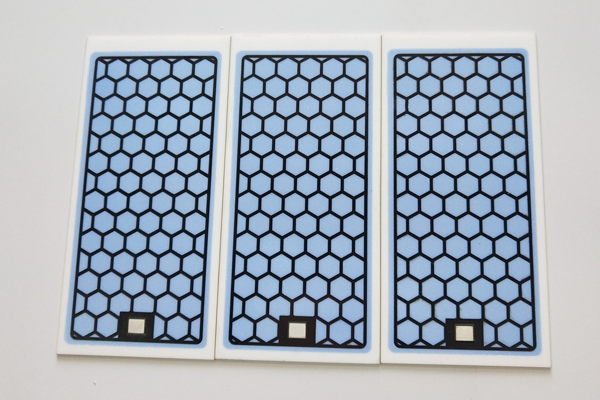

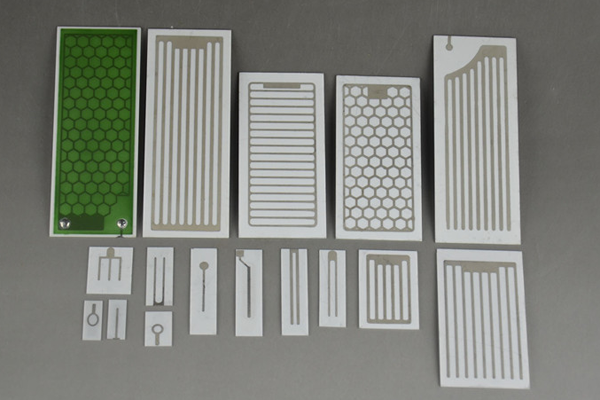

Ozone Generator Ceramic PCB

What's Ozone Generator Ceramic PCB ?

|

Ozone Generator Ceramic PCB Using thick film carbon printing and high-temperature sintered nickel electrode process, It has the advantages of stable electrode operation, large amount of ozone, moisture resistance, oxidation resistance, electrode not easy to fall off, short start-up time, low power consumption and long service lifece. Ozone Generator Thick Film Ceramic PCB technology is a new material that will improve the process of embedded resistors by eliminating the need for special termination treatment, such as immersion silver,or silver palladium, gold palladium, Also speed up the laser trim process with tighter TCR’s; and increase the reliability performance with a stable binder system.Thus far, The environmental and mechanical testing of Ozone Generator Thick Film Ceramic PCB processing has also been successful. Continuing to test and formulate higher resistivity values will prove these thick film resistor technology has a future in the embedded passives market. Layers:1 Layer For more information, Please refer to "Thick-Film-Hybrid-Circuit" |

|

|

|

|

|