High Frequency PCB

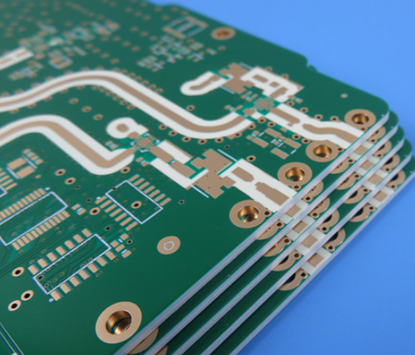

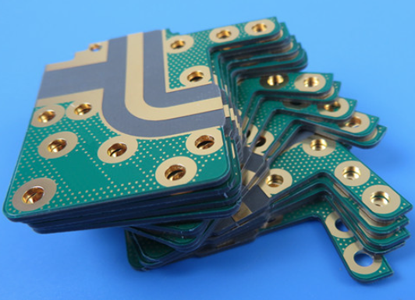

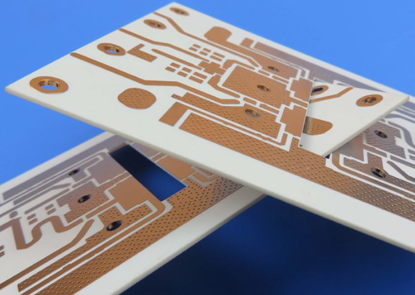

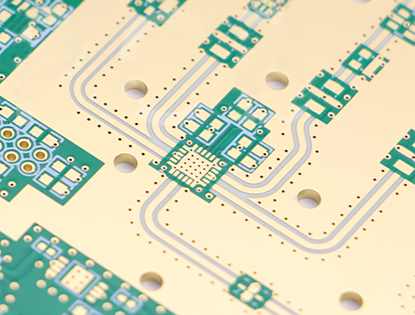

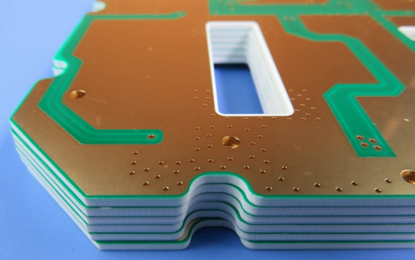

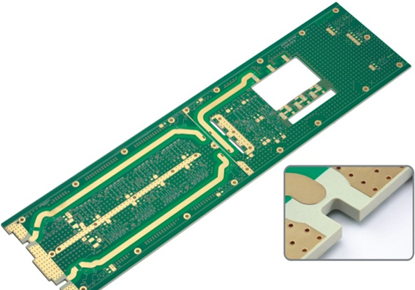

High-Frequency PCBs, also known as Radio Frequency PCBs, are printed circuit boards designed for signal transmission with special requirements, aiming to transmit high-frequency signals with minimal signal loss and impedance mismatch, featuring properties such as low dielectric constant (Dk), low loss factor (Df), and low coefficient of thermal expansion (CTE), typically used in applications operating in the RF range, usually above 100 MHz, extending to several GHz or even tens of GHz. High Frequency PCBs (HF PCBs) are commonly used in wireless communication systems, microwave systems, radar systems, and satellite communications, in particular the popularity of 3G networks exacerbate the market demand for the product on the high frequency PCB, where signal integrity and reliability are critical, so the design and fabrication of High Frequency PCBs require specialized knowledge and techniques to ensure optimal performance of the final product. Radio Frequency PCBs (RF PCBs) made from polytetrafluoroethylene (PTFE), ceramic-filled fluoropolymer, or ceramic-filled hydrocarbon thermosets materials with improved dielectric properties.These materials have a low dielectric constant of 2.0-3.8, a low loss factor, excellent low-loss characteristics, and favourable properties such as high glass transition temperature, very low hydrophilic rate, and excellent thermal durability. Development Prospect of High Frequency PCB : |

|

|

|

High Frequency PCBs have a promising development prospect due to the increasing demand for high-frequency applications across various industries. As technology continues to advance, the need for high-speed and high-frequency electronic devices is growing rapidly, and HF PCBs play a crucial role in meeting these demands by enabling the transmission of signals at frequencies above 100 MHz, extending to several GHz or even tens of GHz, with minimal loss and impedance mismatch. ● One of the key factors driving the growth of the High Frequency PCB market is the expansion of wireless communication systems, including 5G networks, Internet of Things (IoT) devices, and other wireless technologies. These systems require high-performance PCBs to ensure reliable signal transmission and data integrity. |

|

|

● Moreover, the aerospace and defense industries are also significant contributors to the demand for High Frequency PCBs. Radar systems, satellite communications, and other high-frequency applications in these sectors rely on advanced PCB technology to achieve optimal performance in challenging environments. ● Additionally, the automotive industry is another emerging market for High Frequency PCBs. With the development of autonomous vehicles, advanced driver-assistance systems (ADAS), and in-vehicle networking, there is a growing need for high-frequency PCBs to support the increasing complexity of electronic systems in modern vehicles. ● Furthermore, the rise of emerging technologies such as artificial intelligence (AI), virtual reality (VR), and augmented reality (AR) is driving the demand for high-speed data processing and transmission, which can be facilitated by High Frequency PCBs. ● High Frequency PCBs have a bright development prospect, driven by the evolving technological landscape and the increasing adoption of high-frequency applications across various industries. As the demand for faster and more reliable electronic devices continues to rise, High Frequency PCBs will play a crucial role in enabling the next generation of high-performance electronics. |

||

Key Features of High Frequency PCB : |

|

1, Low Dielectric Constant (Dk): High Frequency PCBs are designed with materials that have a low Dk, which is the measure of the ability of a material to store electrical energy in an electric field. This property ensures minimal signal loss and distortion. |

|

|

2, Low Dissipation Factor (Df): High Frequency PCBs have a low Df, which is the measure of the power lost as heat during the transmission of signals. This characteristic ensures minimal signal attenuation and enables high-frequency transmission. 3, Low Coefficient of Thermal Expansion (CTE): High Frequency PCBs exhibit a low CTE, which ensures dimensional stability and prevents damage during temperature changes. 4, High Thermal Stability: These PCBs are designed with materials that can withstand high temperatures, ensuring reliable performance even in demanding environments. 5, Excellent Signal Integrity: High Frequency PCBs are designed to minimize signal loss and distortion, ensuring excellent signal integrity across a wide frequency range. 6, High Frequency Performance: High Frequency PCBs are specifically designed to operate at high frequencies, ranging from 100 MHz up to several GHz or even tens of GHz. |

|

7, Customizable Design: High Frequency PCBs can be customized to meet specific design requirements, enabling the development of high-performance electronic devices for various applications. These key features make High Frequency PCBs ideal for applications that require reliable signal transmission at high frequencies, such as wireless communication systems, radar systems, satellite communications, and other high-speed electronic devices. |

|

Why Needs High Frequency PCB ? |

High Frequency PCBs are needed for various applications that require high-speed signal transmission and minimal signal loss. Here are some reasons why high frequency PCBs are necessary: 1, Signal Integrity: High frequency PCBs are designed to minimize signal loss, distortion, and interference, ensuring the integrity of signals transmitted at high frequencies. |

|

|

2, Reduced Electromagnetic Interference (EMI): High frequency PCBs are engineered to reduce electromagnetic interference, which is crucial for electronic devices operating in high-frequency ranges. 3, Improved Impedance Control: High frequency PCBs offer better control over impedance matching, which is essential for maintaining signal integrity and minimizing reflections in high-speed digital circuits. 4, Lower Loss Tangent: High frequency PCB materials have a lower loss tangent, which results in lower signal attenuation and better signal propagation at high frequencies. 5, High-Speed Data Transmission: High frequency PCBs are essential for applications that require high-speed data transmission, such as telecommunications, wireless communication, radar systems, and high-performance computing. |

6, RF and Microwave Applications: High frequency PCBs are commonly used in RF (radio frequency) and microwave applications due to their superior performance at higher frequencies. 7, Miniaturization: High frequency PCBs allow for the design of compact and lightweight electronic devices, making them ideal for portable and space-constrained applications. High Frequency PCBs are needed for applications that require efficient transmission of signals at higher frequencies, typically above 100 MHz. These PCBs are crucial for minimizing signal loss, interference, and impedance mismatches, which are common at high frequencies. As technology advances, the demand for faster, more reliable communication and high-speed data transmission grows, especially in areas like wireless communication, radar systems, satellite communication, and high-performance electronics. High Frequency PCBs ensure that these devices can function effectively, delivering optimal performance while maintaining signal integrity, which is essential for applications in industries such as telecommunications, aerospace, medical devices, and consumer electronics. |

|

Design Rules of Radio Frequency PCB : |

1, Minimize Vias: To prevent impedance discontinuities and signal integrity issues, minimize the use of vias in the PCB design. If vias are necessary, ensure they are placed away from signal lines or PCB traces. 2, Reduce Crosstalk: Layout considerations play a crucial role in reducing crosstalk. Maintain a center-to-center separation between traces, avoid parallel routing of clock lines, and keep a significant distance between low voltage differential clock signals and high frequency signals. |

|

|

3, Separate Signals and Power Supply: Separate analog and digital signals by designing separate power supply layers. This separation helps in shielding crosstalk. Similar to separating digital and analog signal grounds, establish separate power supplies for these signal types. 4, Avoid Loops: It is advisable to avoid using loops in high frequency PCB designs as they can contribute to crosstalk. If loops are necessary, restrict their area to facilitate signal flow in the circuit board. 5, Signal Ground Isolation: Isolate the digital signal ground from the analog signal ground to prevent interference from higher digital signals affecting analog signals at the PCB's ground plane. 6, Minimize Trace Bends: Keep PCB traces as straight as possible to maintain impedance continuity and enhance coupling of high frequency signals. Avoid using non-straight or bent traces as they can introduce impedance issues. |

7, Parallel Wires with Adequate Spacing: Utilize shorter paralleled wires and provide sufficient spacing between them. This design approach helps reduce electromagnetic field interactions, also known as the "mutual effect," between the wires. |

|

Advantages of High Frequency PCB : |

1, Improved Signal Integrity: High frequency PCBs are designed to minimize signal loss, distortion, and interference, ensuring the integrity of signals transmitted at high frequencies. This results in better overall performance and reliability of electronic devices. 2, Reduced Electromagnetic Interference (EMI): High frequency PCBs are engineered to reduce electromagnetic interference, which is crucial for electronic devices operating in high-frequency ranges. This helps maintain signal quality and prevent disruptions caused by external electromagnetic waves. |

|

|

3, Enhanced Impedance Control: High frequency PCBs offer better control over impedance matching, which is essential for maintaining signal integrity and minimizing reflections in high-speed digital circuits. This allows for more accurate transmission of high-frequency signals. 4, Lower Signal Loss: High frequency PCB materials have lower loss tangents, meaning they exhibit lower signal attenuation. This results in improved signal propagation and reduced signal loss, especially at higher frequencies. 5, High-Speed Data Transmission: High frequency PCBs are essential for applications that require high-speed data transmission, such as telecommunications, wireless communication, radar systems, and high-performance computing. They enable reliable and efficient data transmission at fast rates. |

6, Suitability for RF and Microwave Applications: High frequency PCBs are commonly used in RF (radio frequency) and microwave applications due to their superior performance at higher frequencies. They can handle the unique requirements of these applications, including impedance matching, low signal loss, and reduced EMI. 7, Compact and Lightweight Design: High frequency PCBs allow for the design of compact and lightweight electronic devices. Their smaller form factor and optimized layout contribute to space-saving designs, making them ideal for portable and space-constrained applications. High Frequency PCBs offer advantages in ensuring reliable signal transmission, minimizing interference, and supporting high-speed data communication, making them indispensable in various industries, particularly those involving wireless communication and high-frequency applications. |

|

Typical Applications of Radio Frequency PCB : |

Radio Frequency PCBs find applications in various industries and technologies that require reliable signal transmission and high-speed data communication at elevated frequencies. Some typical applications include: 1, Wireless Communication: Radio Frequency PCBs are extensively used in wireless communication systems such as cellular networks, Wi-Fi routers, satellite communication systems, and Bluetooth devices. These PCBs enable efficient transmission and reception of signals in the radio frequency (RF) range. 2, Microwave Systems: Radio Frequency PCBs are essential components in microwave systems, including microwave transceivers, microwave amplifiers, and microwave antennas. These systems operate at higher frequencies and require precise control of impedance, signal integrity, and low loss. |

|

|

3, Aerospace and Defense: High Frequency PCBs play a critical role in aerospace and defense applications, including avionics systems, radar systems, communication systems, and electronic warfare equipment. They are designed to withstand harsh environments and ensure reliable performance in demanding conditions. 4, Data Centers and High-Performance Computing: High Frequency PCBs are employed in data centers and high-performance computing systems to enable fast and reliable data transfer between servers, network switches, and storage devices. They support high-speed interconnectivity and data transmission at elevated frequencies. 5, Radar Systems: Radar systems rely on high frequency signals for detecting and tracking objects. High Frequency PCBs play a crucial role in radar systems, including weather radar, air traffic control radar, and automotive radar, by ensuring accurate signal processing and transmission. |

6, Satellite Communication: Satellite communication systems involve transmitting and receiving signals over long distances. High Frequency PCBs are integral to these systems, ensuring reliable data transmission at high frequencies between satellites and ground stations or other satellites. 7, Test and Measurement Instruments: Radio Frequency PCBs are utilized in test and measurement instruments such as oscilloscopes, spectrum analyzers, network analyzers, and signal generators. These PCBs enable accurate measurement and analysis of high frequency signals. 8, Medical Imaging Equipment: Radio Frequency PCBs are used in medical imaging equipment such as MRI (Magnetic Resonance Imaging) machines, CT (Computed Tomography) scanners, and ultrasound devices. These PCBs support the high-speed data processing and signal integrity required for accurate medical diagnostics. |

|

Engineering SPEC of High Frequency PCB : |

Typical Properties of High Frequency PCB : |

Raw Materials Used For High Frequency PCB : |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Raw Materials Datasheet of High Frequency PCB : |

High-Frequency PCB have special demands on the material used, Please check material datasheets as following for your reference :

Materials : |

Dk (@10GHz) |

Df (@10GHz) |

Z CTE (ppm/°C) |

Surface Resistivity (MΩ) |

Thermal Conductivity(W/m·K) |

Peel Strength (N/mm) |

2.52 |

0.0013 |

196 |

4.1 x 107 |

0.33 |

2.6 |

|

3.38 |

0.0027 |

46 |

4.2 x 109 |

0.71 |

1.05 |

|

3.48 |

0.0037 |

32 |

5.7 x 109 |

0.69 |

0.88 |

|

2.33 |

0.0012 |

173 |

2 x 107 |

0.22 |

27.2 |

|

2.2 |

0.0009 |

237 |

3 x 107 |

0.2 |

31.2 |

|

3 |

0.0013 |

25 |

1 x 107 |

0.5 |

2.2 |

|

6.2 |

0.002 |

24 |

1 x 105 |

0.79 |

1.2 |

|

10 |

0.0022 |

16 |

1 x 105 |

0.95 |

1.6 |

|

4.5 |

0.008 |

55 |

2.8 x 106 |

– |

1.2 |

|

3.5 |

0.0018 |

64 |

1.5 x 108 |

0.24 |

1.8 |

|

2.5 |

0.0019 |

135 |

1 x 107 |

0.19 |

2.1 |

|

3.2 |

– |

70 |

1 x 107 |

0.24 |

2.1 |

|

4.2 |

0.01 |

55 |

1.6 x 109 |

0.2 |

1.2 |