PCB Assembly Services (PCBA)

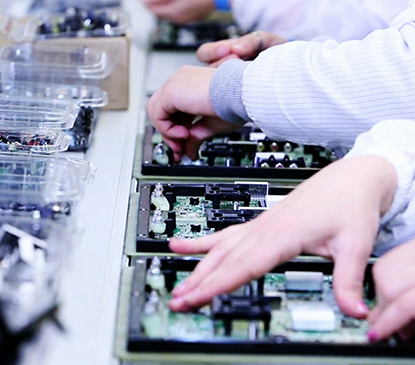

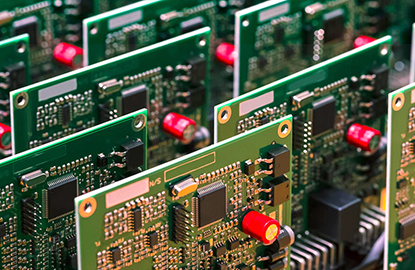

PCB Assembly Services, also called PCBA Services, refer to the processes of mounting electronic components onto printed circuit boards (PCBs). These services include multiple steps such as designs, assemblies, solderings, and testing. Initially, the PCB assembly providers manufacture the circuit boards based on the clients’ design schematics, then mount various electronic components (such as resistors, capacitors, transistors, IC chips, etc.) through Surface Mount Technology (SMT) or Through-Hole Technology. PCB Assembly Services involve the entire process, from raw material procurement and PCB manufacturing to final product testing. Soldering is one of the key steps, and modern SMT equipment can achieve high-speed, efficient component installation through automated production lines. After soldering, electrical testing (such as ICT, AOI, and FCT) is typically performed to ensure correct circuit connections and functionality. Through this series of processes, PCB Assembly Service ensures high-quality circuit board assembly to meet the needs of different clients, widely applied in consumer electronics, telecommunications, automotive electronics, and more. Component Procurement of PCB Assembly Services : |

|

|

|

1, Why Outsource Electronic Components ? ● Customers only need to provide design files, allowing electronic manufacturers to source components and complete the PCBA production process as per the design specifications. This "turnkey" approach helps save on labor and inventory costs, as well as the costs associated with building an in-house procurement and inspection system. |

|

2, Ensuring Quality in Component Procurement: 3, Advantages of Sourcing Electronic Components: ● When customers source components themselves, they often buy from various online distributors, which may lead to inconsistent quality and suboptimal pricing. |

||

|

4, Storing Electronic Components: ● Electrostatic Protection: Electrostatic discharge can severely damage electronic components, especially integrated circuits (ICs). Therefore, it is essential to use electrostatic protective packaging materials, such as anti-static bags or foams, and take precautions with anti-static workstations and tools to reduce static damage. ● Categorized Storage: To facilitate management, electronic components should be stored in an organized manner by type, specification, or model. For example, using drawer-style storage boxes or racks specifically designed for electronic components allows for easy identification and retrieval. |

|

● Dust Prevention: Dust and debris can negatively impact the functionality of electronic components, so it is important to maintain a clean environment during storage. Anti-dust packaging and sealed storage boxes can effectively prevent dust from entering components. ● Corrosion Prevention: Some electronic components, such as metal pins and surfaces, can be prone to corrosion. Using anti-corrosion agents, desiccants, and other materials can help protect components from oxidation or other corrosive elements during storage. ● Shelf Life: Certain components, particularly those containing chemical substances (e.g., electrolytic capacitors and some types of semiconductor components), may have a recommended storage or shelf life. After this period, their performance may degrade, or they may become unreliable. It is important to check the manufacturing date and mark the storage duration of components. |

||

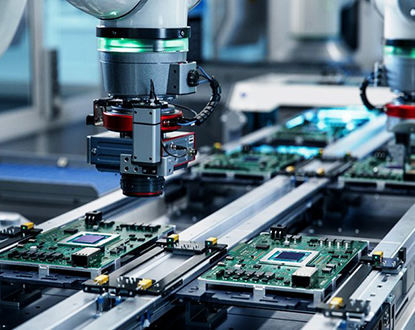

SMT (Surface Mount Technology) of PCB Assembly Services : |

PANDA PCB offers high-end SMT Assembly Services, equipped with three fully automated, high-speed SMT production lines, automatic placement machines, automatic solder paste printers, SPI solder paste thickness detectors, multi-zone reflow ovens, AOI optical inspection systems, X-ray machines, and baking ovens. We provide long-term processing and manufacturing services to both domestic and international companies. Our company is certified with ISO 9001:2015 quality management system and IATF 16949 automotive electronics certification. We support assembly of precision electronic components such as 0201, 0.4mm pitch BGAs, QFNs, etc. |

|

|

1, Advantages of SMT Assembly: ● Our team of 15 electronic engineers checks manufacturability (DFM) and provides constructive suggestions to improve product quality and production efficiency. ● We implement a Quick Response mechanism, with professional sales representatives ready to respond to any issues within one hour. ● We utilize MES electronic information systems to track and monitor production plans, ensuring timely delivery. ● ESD static protection materials such as anti-static foam or bags are used for safe packaging, ensuring product safety during transport. |

2, How to Collaborate on SMT Assembly: |

|

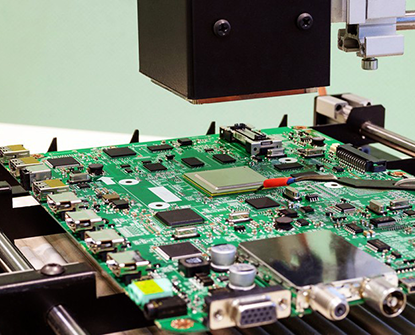

DIP (Dual In-line Package) Assembly of of PCBA Services : |

DIP assembly is a part of the PCBA electronic manufacturing process, involving more manual labor and requiring stricter management. We have implemented a comprehensive quality management system (ISO 9001:2015, IATF 16949) and continuously upgraded automation equipment, such as automatic depaneling machines, automatic dispensing machines, and automatic soldering machines, ensuring a high level of consistency and reliability in our DIP services, which has earned us customer praise. DIP Assembly Capabilities: ● Our skilled operators, trained in soldering, ensure controllable speed and quality. ● We maintain designated temporary storage areas for different stages of the process (e.g., waiting for assembly, awaiting repairs, QC inspection, defective products, QA inspection) to prevent board mix-ups. ● Strict IPQC and QA lot sampling standards ensure the reliability of the DIP process. |

Final PCBA Testing of PCB Assembly Services : |

|

PCBA Testing refers to the process of checking the electrical connectivity and input/output values on a mounted PCBA circuit board. 1, PCBA Testing Principles: ● The MCU program captures user actions (e.g., pressing a switch for 3 seconds) and controls the nearby circuit to perform actions (e.g., turning on LEDs or rotating motors). ● By observing voltage and current values between test points and verifying whether the input/output actions match the design, we complete testing of the entire PCBA board. |

2, Types of PCBA Testing: ● FCT (Functional Test): Requires uploading an MCU program into a program IC, performing functional tests (e.g., button press triggers LED light). ● Burn-In Test: Involves simulating user input/output over an extended period to check durability and soldering reliability. |

|

Conformal Coating of PCB Assembly : |

Conformal Coating is a special formulation used to protect circuit boards and related devices from environmental damage. It has excellent high and low-temperature resistance and, after curing, forms a transparent protective layer that provides insulation, moisture-proof, anti-leakage, anti-vibration, anti-dust, anti-corrosion, and anti-aging properties. We are equipped with two specialized conformal coating production lines, which include two coating machines, UV detection, and automatic baking systems. If your PCBA requires protection from temperature, humidity, durability, insulation, or waterproofing, we can meet those needs. |

|

|

1, Supported Conformal Coating Types: ● PCBA carriers to ensure uniform edge coating. ● Suitable for densely populated PCBA boards with tall components. ● Combines fan-shaped and dot spraying techniques to cover various component surfaces. ● Allows selective coating for specific components like connectors, antennas, Wi-Fi modules, and heat sinks. ● Dual-side coating and baking. ● Automatic equipment with an average coating time of 0.5-3 minutes per board. |

Final Assembly of PCBA Services : |

PANDA PCB offers electronic product assembly services, including industrial controllers, consumer electronics, IoT modules, and electrical equipment. After testing, we assemble the PCBA boards with enclosures, wiring, motors, and other components to form complete products for end-users. Electronic assembly, as an essential part of EMS (Electronic Manufacturing Services), involves more manual labor and requires stringent process control and quality management. 1, Advantages of Final Product Assembly: ● Strict SOPs are followed, covering operational techniques, quality standards, tooling, and statistical analysis. ● On-site QC ensures 100% inspection, and QA performs AQL standard sampling to identify and control defects. ● OBA (Outgoing Box Audit) inspection is done before product shipment. ● The production line is equipped with the necessary tools such as electric screwdrivers, magnifying glasses, torque meters, dispensing machines, and testing racks. ● A clear division of material areas on the assembly line prevents material and board mix-ups. ● We have extensive experience in assembling precise and complex products. |