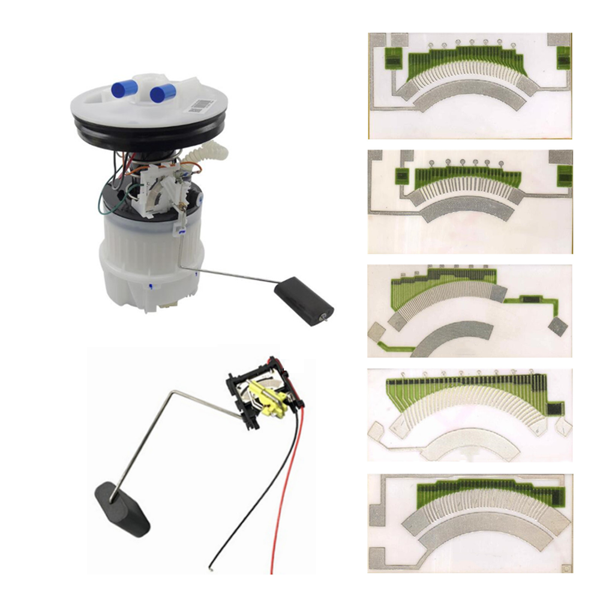

Fuel Level Sensor Thick Film Ceramic PCB

What's Fuel Level Sensor Thick Film Ceramic PCB?

Fuel Level Sensor Thick Film Ceramic PCB for automobile is suitable for the measurement of various fuel oils under normal temperature and pressure. The output damping time is adjustable from 30 to 180s and can be equipped with 485 communication, In fuel level sensor assemblies . Fuel Level Sensor Thick Film Ceramic PCB communicates with the vehicle fuel gauge. We can supply individual Fuel Level Sensor Thick Film Ceramic PCB assemblies consisting of the fuel card and tank wire harness. They are used in passenger cars, heavy trucks, motor cycles and scooters.

The Fuel Level Sensor Thick Film Ceramic PCB in automotive applications is typically measured by a float and lever arm assembly that operates a variable resistor mechanism. In many cases, this assembly (known as a fuel sender or fuel level sender) is mounted in the fuel tank and integrated into the fuel delivery module. This module removes fuel from the tank and delivers pressurized fuel to the power train.

SPEC: Resistane Value 0-200 K ohm +/-10% (Customizable)

Linearity tolerance: < +/-1.2%

Fuel Level Sensor Thick Film Ceramic PCB Specification :

1,Ceramic Substrate can be 96% or 98% Alumina (Al2O3) or Beryllium Oxide (BeO), thickness range: 0.25, 0.38, 0.50mm, 0.635mm (default thickness), 0.76mm, 1.0mm. Thicker thickness such as 1.6mm or 2.0mm can be customized too.

2, Conductor layer materail is silver palladium, gold palladium, or Mo/Mu+Ni (for Ozone).

3, Thickness of conductor >= 10 miron (um), and Max can be 20 micron (0.02mm).

4, Min trace width and space for volume production:0.30mm & 0.30mm, 0.20mm/0.20mm is also okay but cost will be higher, and 0.15mm/0.20mm only available for prototype.

5, Tolerance for final trace layout will be +/-10%.

6, Both gold and silver palladium is workable for gold-wire bonding, but customer need to mention that so that we will use special silver palladium which is suitable for that artwork.

7, Gold palladium is much more expensive than silver, about 10~20 times higher.

8, More different resistor value on the same board, more expensive the board will be.

9, Normally layers are 1L and 2L (with plated through hole (PTH), and plated material is the same like the one used for conductor).

10, Soldermask is also available upon request, working temperature >500 C, and color is semi-transparent.

For more information, Please refer to "Thick Film Ceramic PCB"

|