What is FLS PCB ?

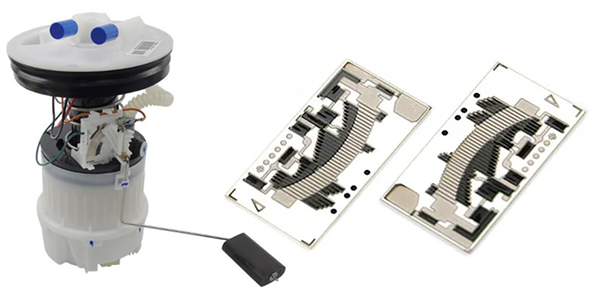

FLS PCBs, short for Fuel Level Sensor Printed Circuit Boards, are specialized electronic components designed for precise monitoring and measurement of fuel levels in various industrial and automotive applications, using ceramic-based substrates combined with thick-film technology to ensure high durability and resistance to harsh environments like temperature fluctuations and vibrations, playing a critical role in fuel management systems by providing a reliable and accurate method for detecting fuel levels in vehicles, machinery, and other equipment, thereby offering essential data for efficient operation and management.

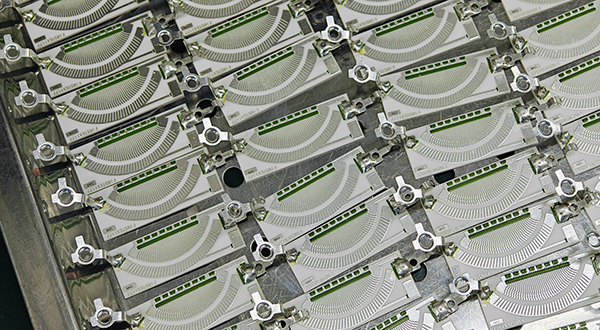

FLS PCBs are produced using a manufacturing process that involves the application of thick-film technology onto ceramic substrates. Conductive materials such as silver and copper are printed onto the ceramic substrate through a screen printing process to create the circuit. This ensures the precision and reliability of fuel level sensing. The ceramic material used in the process provides the necessary mechanical strength and heat resistance, making the PCBs suitable for use in environments subjected to high temperatures and mechanical stress. The entire manufacturing process is carefully controlled to guarantee consistent sensor performance and accuracy throughout its lifespan.

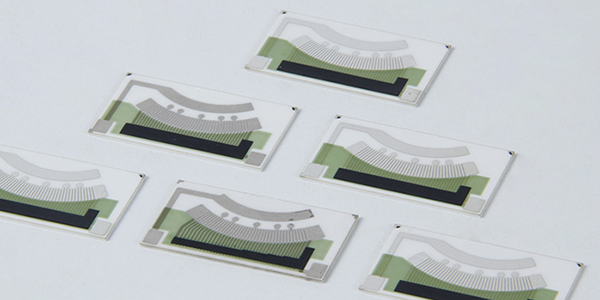

FLS PCBs are known for their exceptional durability, precision, and ability to resist harsh environmental conditions. By using ceramic substrates and thick-film technology, these PCBs can withstand extreme temperatures, vibrations, and other environmental challenges typically found in industrial and automotive settings. These sensors offer high accuracy in detecting fuel levels, which ensures reliable operation of fuel management systems. Moreover, the robust design of FLS PCBs allows them to function over long periods, delivering long-term performance even in demanding environments, making them ideal for applications requiring high reliability and precision.

Fuel Level Sensor Printed Circuit Boards are widely utilized in various industrial and automotive applications where monitoring fuel levels is critical. They are essential components in fuel management systems for vehicles like cars, trucks, and machinery, as well as for specialized equipment used in industries such as construction, agriculture, and transportation. By providing real-time data on fuel levels, FLS PCBs help optimize fuel usage, improve fuel efficiency, and ensure safe operation. Their durability and reliability make them suitable for use in challenging environments, ensuring accurate fuel level measurements even under extreme conditions.

Main Features of FLS PCB :

● Ceramic Substrate: The core of the FLS PCB is a high-quality ceramic substrate that offers excellent thermal and mechanical stability.

● Thick-Film Technology: Employing thick-film technology allows for the creation of robust conductive patterns that can endure extreme temperatures and pressures.

● High-Temperature Resistance: Capable of operating in high-temperature environments without performance degradation.

● Chemical Resistance: Resistant to various chemicals, including fuels and lubricants, ensuring a long service life.

● Precision Sensing: Equipped with sensitive components that accurately detect even the slightest changes in fuel levels.

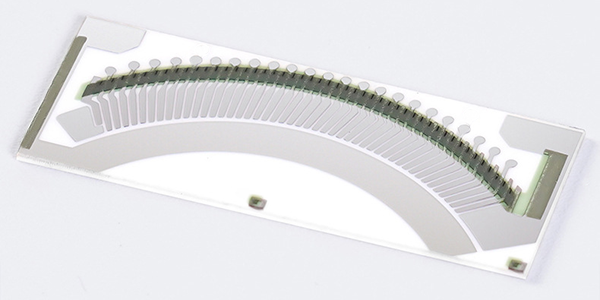

● Compact Design: Space-efficient design suitable for integration into tight spaces within fuel tanks and other confined environments.

Advantages of FLS PCB :

● Durability: The use of ceramic materials and thick-film technology results in a highly durable product with a long lifespan.

● Reliability: Consistent performance in a wide range of operating conditions, reducing the likelihood of sensor failure.

● Accuracy: High-precision measurements ensure that fuel levels are accurately reported, enhancing safety and efficiency.

● Environmental Resistance: The ability to resist harsh environmental factors makes the Fuel Level Sensor PCB suitable for various industries.

● Cost-Effectiveness: While offering premium performance, the Fuel Level Sensor PCB is designed to be cost-effective for long-term use.

Applications of FLS PCB :

● Automotive Industry: FLS PCBs are integral components in fuel management systems for cars, trucks, and other vehicles. They help monitor fuel levels in real time, ensuring efficient fuel usage and optimizing performance.

● Machinery: FLS PCBs are used in heavy machinery and construction equipment to ensure that the fuel systems operate efficiently and to prevent fuel-related issues by providing accurate fuel level readings.

● Agriculture and Construction Equipment: These PCBs are used in specialized equipment like tractors, harvesters, and construction vehicles, where fuel management is crucial for performance and safety.

● Transportation: For transportation fleets, FLS PCBs provide real-time fuel data, helping operators optimize fuel consumption, reduce costs, and ensure safe operation, particularly in long-distance transportation.

● Industrial Machinery: In industries with high operational demands, FLS PCBs ensure that fuel levels are accurately monitored to avoid downtime due to fuel shortages, ensuring smoother operations and efficiency.

● Emergency and Backup Generators: In backup power systems, FLS PCBs help monitor fuel levels to ensure that generators operate without interruption, particularly in critical situations like power outages.

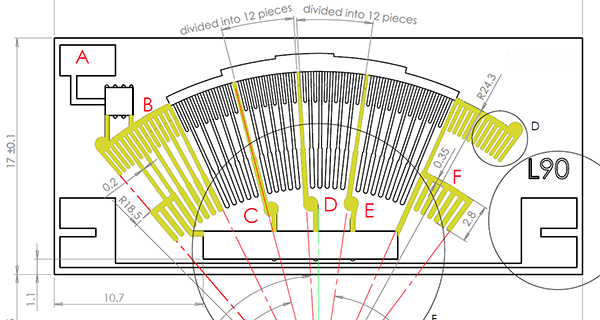

Design Guidelines of FLS PCB :

● Material Selection: Choose the appropriate ceramic material based on the application's thermal and mechanical requirements.

● Thick-Film Patterning: Design the conductive patterns using thick-film technology to ensure optimal electrical performance.

● Component Integration: Integrate sensing components that are compatible with the ceramic substrate and capable of withstanding the application's environmental conditions.

● Testing and Validation: Conduct rigorous testing to validate the performance of the FLS PCB under various conditions.

● Customization: Offer design flexibility to meet the specific needs of different applications, including size, shape, and sensor type.

● Dimensional Considerations: Design FLS PCB dimensions to fit within the available space in the fuel tank or application environment.

● Electrical Specifications: Ensure adherence to electrical parameters suitable for accurate fuel level measurement.

● Testing and Calibration: Implement rigorous testing procedures to validate performance and calibrate as needed for precise measurements.

For more information, Please refer to Thick Film Ceramic PCB.