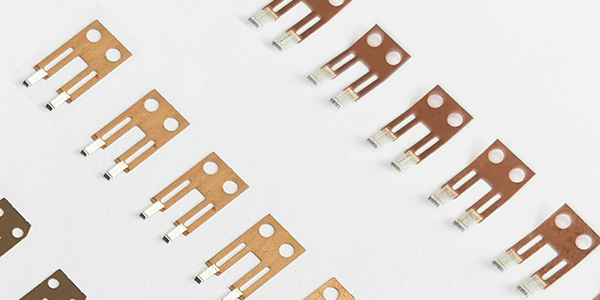

Precious Metal Spring Contacts

Precious Metal Spring Contacts, also called Precious Metal Spring Brushes, are high-performance sliding contacts designed for potentiometer sensors. They feature precious metal alloy wires mounted on beryllium copper spring bases. Their multi-finger design ensures redundant and reliable contact, offering exceptional durability, corrosion resistance, and stable performance under extreme temperatures. These contacts are critical in harsh environments, ensuring precise, noise-free signal transmission in automotive position sensors, aerospace controls, and industrial instrumentation.

Functions of Precious Metal Spring Contacts :

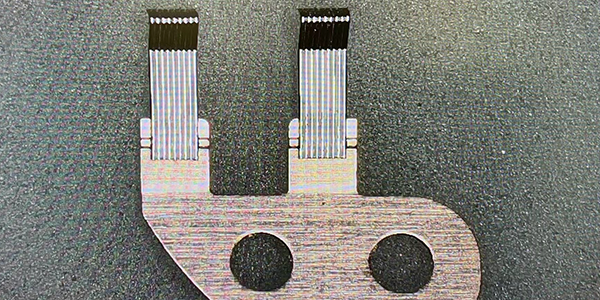

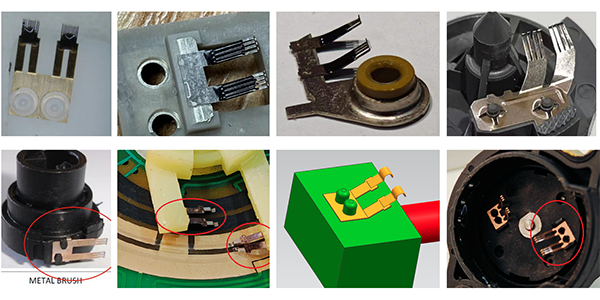

Precious Metal Spring Contacts are essential sliding contact components in potentiometer-type sensors, establishing reliable electrical connections with resistive conductors to transmit precise signals. These contacts operate as multi-point brush systems, maintaining continuous electrical engagement with conductive tracks, typically made of conductive plastic, carbon film, or precious metal thick film, while accommodating rotational or linear movement. Their primary role is to ensure stable, low-resistance signal transmission with minimal electrical noise, enabling accurate position sensing in applications such as throttle position sensors, pedal sensors, and rotary encoders. The multi-wire brush design creates redundant contact points that enhance reliability by preventing signal interruption even if individual wires encounter debris or wear.

Processes of Precious Metal Spring Contacts :

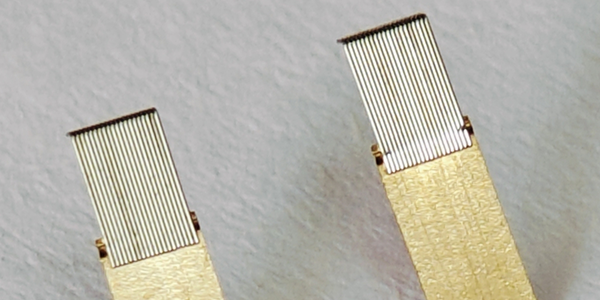

The manufacturing process involves precision engineering that combines precious metal alloys with resilient spring bases. The contacts are fabricated by spot-welding proprietary precious metal alloy wires (containing gold, silver, platinum, palladium, copper, and zinc in controlled compositions) onto hardened CuBe2 beryllium copper spring bases to achieve specific hardness levels (HV 240-330). Advanced techniques include drawing and sample-based manufacturing for OEM customization, rapid prototyping for quick validation, and precision clamping between phenolic fiber insulating strips. For scratch brush variants, high-performance precious metal clad materials are selectively applied only to contact areas to optimize the cost-performance ratio. The process ensures unit pressure exceeding 10,000 psi while maintaining elasticity within the spring's fatigue limit, eliminating welded joint failure modes.

Features of Precious Metal Spring Contacts :

These contacts deliver exceptional longevity, exceeding 2 million mechanical cycles, far surpassing standard brushes rated at approximately 0.5 million cycles, due to superior material properties and mechanical design. Key characteristics include:

● Ultra-low and stable contact resistance ensured by gold/silver content.

● Excellent corrosion resistance from platinum/palladium for harsh automotive and industrial environments.

● High mechanical durability that resists flattening and deformation.

● Multi-point contact structure providing redundancy and high reliability.

● Low-torque operation suitable for miniaturized designs.

● Stable contact force maintained by spring materials.

The multi-wire configuration (3-28 wires of φ0.05-0.15mm) enables reading signals from fine-patterned circuits, facilitating product miniaturization while maintaining consistent performance across temperature ranges from -65°C to +220°C.

Applications of Precious Metal Spring Brushes :

Precious Metal Spring Brushes are extensively used in high-reliability applications that demand precise positional feedback under severe environmental conditions. Primary applications include automotive sensors (throttle position, pedal position, vehicle height, and EGR systems), high-precision potentiometers for aerospace and military controls, industrial process control equipment, camera controls, and coal cutting machinery. They are critical in conductive-plastic rotary potentiometers for aircraft fly-by-wire systems, where multi-finger precious metal sliding contacts combined with conductive-plastic tracks achieve virtually infinite resolution, low noise, and excellent vibration/shock performance. Additional uses include flexible displays, medical devices, wearable electronics, and instrumentation counters requiring repeatability and superior performance in extreme conditions.

For more information, Please refer to Multi-Wire Wipers.