What is Laser Trimming ?

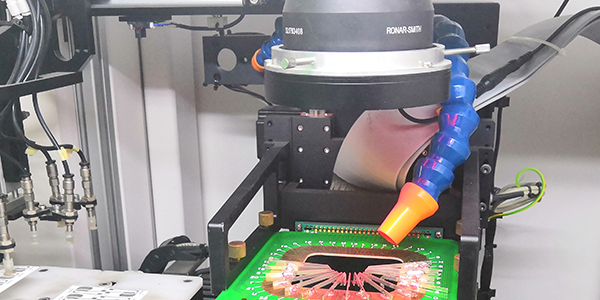

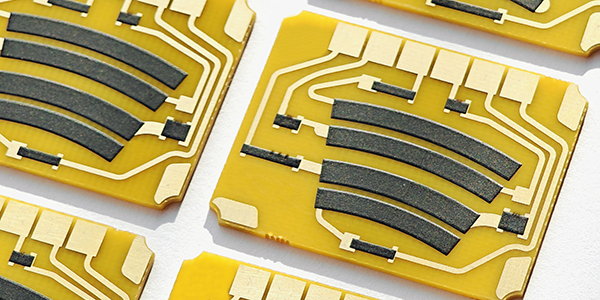

Laser Trimming is a precision process used to adjust the resistance values of resistors, particularly thick-film resistors, to achieve high accuracy and linearity. It involves using a laser to selectively remove small portions of the resistor material, fine-tuning its resistance to meet specific requirements. This method allows for precise adjustments without affecting the overall structure of the component. Laser trimming is commonly employed in the manufacturing of electronic components where resistance stability is critical, ensuring that the final product meets stringent performance standards.

Why Laser Trimming Important for APP Sensor ?

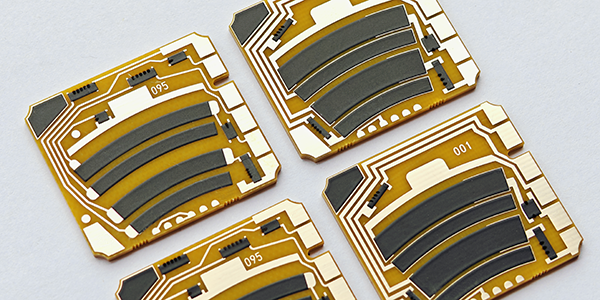

In the automotive industry, the Accelerator Pedal Position Sensor (APP Sensor) plays a vital role in converting the driver's accelerator pedal position into an electronic signal, which is then transmitted to the engine control unit (ECU) or other vehicle control systems. The precision of the resistor linearity in the APP Sensor is crucial, as even small errors can affect acceleration response and, consequently, vehicle safety and driving experience. Laser trimming is particularly important in APP Sensor-PCBs, where thick-film resistors are used. It ensures the resistor's linearity and minimizes manufacturing process errors, ultimately enhancing the sensor's performance, stability, and durability. By employing laser trimming, manufacturers can ensure high reliability and accuracy, meeting the rigorous demands of the automotive industry.

Advantages of Laser Trimming Technology :

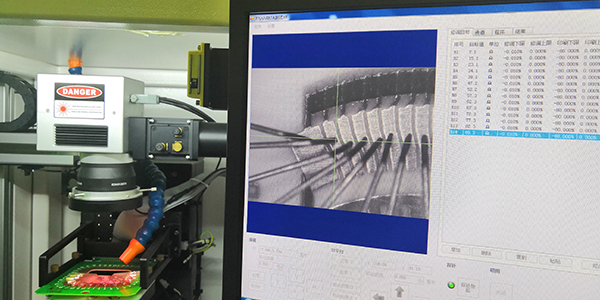

● To overcome this problem, laser trimming technology has been applied in the manufacturing process of thick-film resistors. Laser trimming uses a high-precision laser beam to precisely adjust the resistance value, significantly improving the resistor linearity. This technology allows for fine adjustments to the resistor path to ensure smooth and consistent changes in resistance, thus optimizing its linearity.

● With laser trimming, the resistor linearity of thick-film resistors can be controlled within a smaller error range, usually within +/-1.0%, and high-precision trimming processes can reduce the error range to +/-0.25%. This significant improvement in resistor linearity is crucial for the accelerator pedal position sensor, as it greatly enhances the sensor's performance and stability.

Impact of Laser Trimming For Resistor Linearity :

1, Improved Sensor Accuracy and Responsiveness :

The working principle of the accelerator pedal position sensor relies on the variation in resistance to reflect the pedal position, which is then converted into an electrical signal transmitted to the ECU. If the resistor linearity is poor, the change in resistance may be irregular, causing inaccurate signals to be sent to the ECU, which can affect the engine's acceleration response. Laser trimming technology optimizes the resistor linearity, enabling the sensor to more accurately reflect the pedal position and ensuring a more precise response from the engine and vehicle control systems, providing a smoother and safer driving experience.

2, Enhanced Durability and Stability :

Accelerator pedal position sensors typically operate in environments with significant temperature fluctuations and variable humidity. The instability of resistance could exacerbate with environmental changes, affecting the sensor's performance. Laser trimming improves the resistor linearity, thereby enhancing the sensor's stability in complex working environments, reducing the impact of external factors on sensor performance, and improving the product's durability and long-term reliability.

3, Reduced System Errors and Noise :

Poor resistor linearity can lead to signal fluctuations and noise, which impacts the quality of the accelerator pedal position sensor's output signal. Laser trimming eliminates factors that destabilize the resistance, reduces signal errors, and minimizes noise, thus ensuring the accuracy and clarity of the sensor signal. This is particularly important in automotive electronic control systems that require high-precision signals, especially in autonomous driving and driver-assistance systems, where any signal error could pose safety risks.

4, Improved Production Efficiency and Cost-effectiveness :

Laser trimming technology also offers the advantage of improving production efficiency. By precisely correcting resistance values, fewer defective resistor components are produced, reducing the scrap rate and saving on production costs. At the same time, the laser trimming process is fast and efficient, allowing for large-scale application in production lines, increasing production speed, and ensuring consistency and high quality of the product.

In the Thick Film Resistor PCB production of accelerator pedal position sensors, the linearity of thick-film resistors directly affects the accuracy and reliability of the sensor. By adopting laser trimming technology, the resistor linearity can be effectively improved, significantly enhancing the sensor’s performance and stability. Laser trimming not only optimizes resistor linearity, allowing the accelerator pedal position sensor to more accurately reflect the driver’s actions, but also enhances its durability and long-term stability in complex operating environments. With ongoing technological advancements, laser trimming will play an increasingly important role in the automotive electronics industry, driving the development of intelligent vehicles and improving driving safety and comfort.

By optimizing resistor linearity, the quality and performance of Accelerator Pedal Position sensor PCBs will be greatly improved, enabling them to gain a competitive edge in the increasingly demanding market.