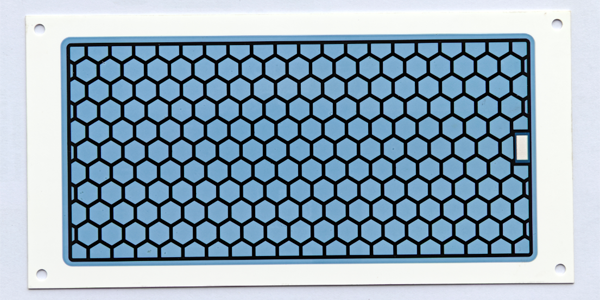

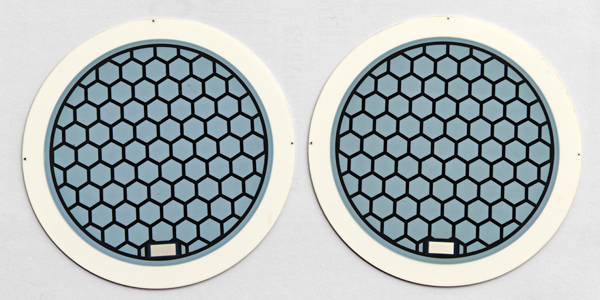

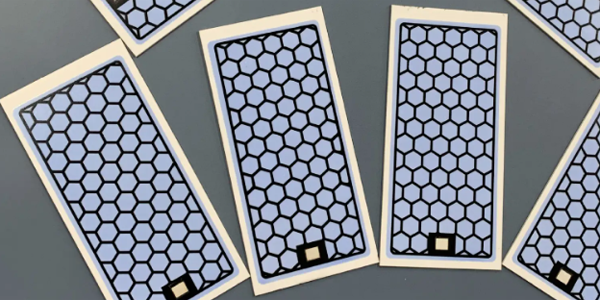

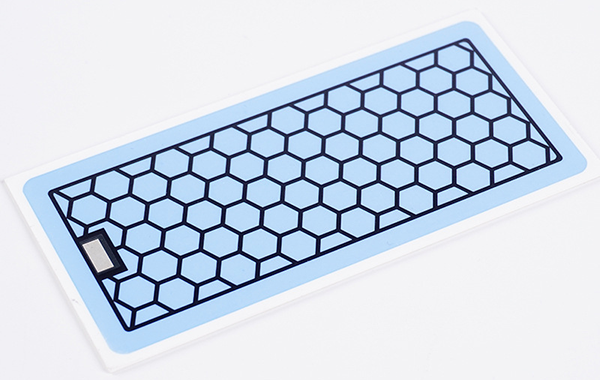

Ceramic Ozone Plates

Ceramic Ozone Plates, also called Ozone Ceramic Plates, are advanced components designed to generate ozone in applications such as air purifiers, water treatment systems, and industrial ozone generators; these plates are crafted from high-quality ceramic materials engineered to facilitate ozone production through corona discharge and are typically coated with an ozone-generating material that becomes activated when high voltage is applied, causing the surrounding oxygen to ionize and produce ozone (O3).

Ceramic Ozone Plates are renowned for their high efficiency and exceptional durability. Their resistance to corrosion and wear makes them ideal for long-term use in continuous ozone generation. The ceramic material can withstand high temperatures and electrical stresses, ensuring a longer lifespan for the plates. Additionally, these plates are engineered to provide stable and consistent ozone output, which is vital for maintaining the effectiveness of ozone-based systems across a wide range of industrial and environmental applications.

Ceramic Ozone Plates operate based on a high-voltage electrical discharge across the ceramic surface, which splits oxygen molecules (O2) into individual oxygen atoms. These atoms then recombine with other oxygen molecules to form ozone (O3). The ceramic material's unique properties allow for efficient ozone production while minimizing plate degradation. As a result, products using ceramic ozone plates benefit from reliable ozone output, making them indispensable for air and water purification, odor removal, and disinfection processes.

Main Features of Ceramic Ozone Plates :

● Material Composition: Ceramic ozone plates are made from materials like aluminum oxide (alumina) or other ceramic compounds known for their high dielectric strength and thermal stability. They may include additives like tungsten, nickel, or molybdenum alloys for the electrode material, which contribute to their stability and performance .

● High Ozone Output: These plates are designed to produce a significant amount of ozone. The ozone generation rate can be substantial, making them suitable for various applications .

● Long Service Life: Ceramic ozone plates are known for their longevity, with some products offering a service life that can range from 3000 to 10,000 hours, depending on the quality and maintenance.

● Resistance to Harsh Conditions: They exhibit resistance to moisture and oxidation, ensuring reliable operation in humid or corrosive environments .

● Low Power Consumption: The plates are engineered to have a low power consumption rate while maintaining high efficiency in ozone production, which is beneficial for energy-saving .

● Temperature Stability: Ceramic ozone plates are designed to operate effectively over a range of temperatures, with some manufacturers taking measures to control the operating temperature to optimize ozone output and reduce the formation of nitrogen oxides (NOx) .

● Easy Integration: They can be easily integrated into ozone generators due to their modular design and are often used in combination with other components to form a complete ozone generation system .

● Safety and Reliability: The design of ceramic ozone plates focuses on safety, ensuring that they can operate for extended periods without the risk of electrode breakdown or other failures .

● Customizability: Some manufacturers offer customizable ceramic ozone plates, allowing for adjustments to suit specific application needs, such as different sizes, shapes, or designs .

● Wide Application Range: They are used in a variety of applications, from air and water treatment to medical and industrial processes, highlighting their versatility .

● Low Maintenance: Due to their robust construction and material properties, ceramic ozone plates require minimal maintenance, which reduces downtime and operational costs .

Operating Principle of Ozone Ceramic Plates :

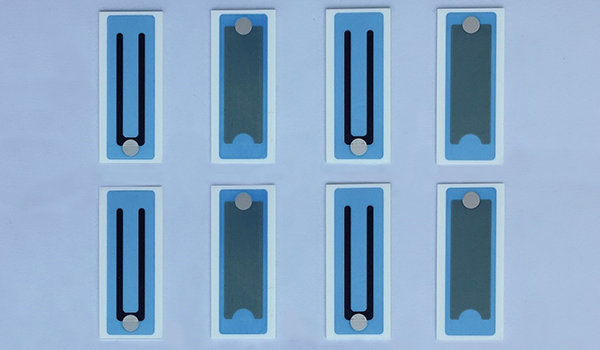

● High Voltage Discharge: Ceramic ozone plates operate by applying high voltage to a dielectric material, typically ceramic. This high voltage creates an electric field strong enough to ionize the oxygen molecules present in the air or pure oxygen gas passing over the ceramic surface.

● Oxidation Process: The ionization process leads to the formation of oxygen ions and electrons. The oxygen ions then react with other oxygen molecules to produce ozone (O3), which is a highly reactive form of oxygen with strong oxidizing properties.

● Dielectric Property: The ceramic material used for the plates is chosen for its high dielectric strength, which allows it to withstand the high voltage without breaking down. This property is crucial for the efficient generation of ozone.

● Electrode Configuration: The ceramic plate is part of an electrode system where it acts as one of the dielectric surfaces between which the discharge occurs. The design of the electrode and the ceramic plate ensures a uniform and stable discharge pattern, which is essential for consistent ozone production.

● Cooling Mechanism: Since the generation of ozone is an exothermic process that produces heat, the ceramic plates may be cooled to maintain optimal operating temperatures. This can be done through water cooling or air cooling systems, which prevent the degradation of ozone due to high temperatures and ensure the longevity of the ozone plates.

● Ozone Collection: The ozone produced is then collected and directed towards its application, such as air or water treatment. The concentration and yield of ozone can be controlled by adjusting the voltage, frequency, and gas flow rate.

● Safety and Stability: Ceramic ozone plates are designed to be stable and safe under the high voltage conditions required for ozone generation. They are also resistant to the corrosive effects of ozone, which can be a problem with other materials.

● Efficiency and Longevity: The ceramic material allows for a high efficiency in ozone production and offers a long service life, with some plates having a lifespan of thousands of hours.

Application of Ceramic Ozone Plates :

● Air Purification: Ozone plates are a core component in air purifiers, where they generate ozone to clean indoor air by breaking down contaminants like volatile organic compounds (VOCs), bacteria, viruses, and odors.

● Water Treatment: In water treatment processes, ozone is used for disinfection and oxidation. Ceramic ozone plates can be integrated into systems to produce ozone, which is then dissolved in water for the removal of harmful substances, including bacteria, viruses, and certain chemicals.

● Wastewater Treatment: Ozone generated by ceramic plates is effective for the degradation of pollutants and the removal of color and odor from wastewater streams, making it useful in both industrial and municipal wastewater treatment plants.

● Food and Beverage Industry: Ozone is used for sanitization in the food and beverage industry to ensure the safety and quality of products. Ceramic ozone plates can be used to generate ozone for cleaning equipment and processing areas, as well as for treating water used in the industry.

● Medical Applications: In medical facilities, ozone can be used for sterilization and disinfection, making ceramic ozone plates useful in operating rooms, laboratories, and other areas where a high level of hygiene is required.

● Swimming Pool and Water Features: Ozone generated by ceramic plates is used as an alternative to chlorine for water sanitation in swimming pools and other water features, providing a more environmentally friendly and less irritating option for users.

● Agriculture: Ozone can be used for soil treatment and water purification in agriculture, helping to control pests and diseases without the use of harsh chemicals.

● Industrial Odor Control: In industries that produce strong odors, such as the food processing and rendering industries, ozone can be used to neutralize the odors at the source.

Safety Considerations of Ozone Ceramic Plates :

● When using ozone generators, ensure adequate ventilation to prevent the accumulation of high ozone concentrations, which can be harmful to human health.

● Follow manufacturer instructions for proper installation and operation to avoid electrical hazards.

● Keep ozone generators away from water to prevent damage and potential electric shock.

● Regularly check for any signs of wear or damage to the components and immediately replace or repair as needed.

More information, Please refer to Thick Film Heating Elements.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters