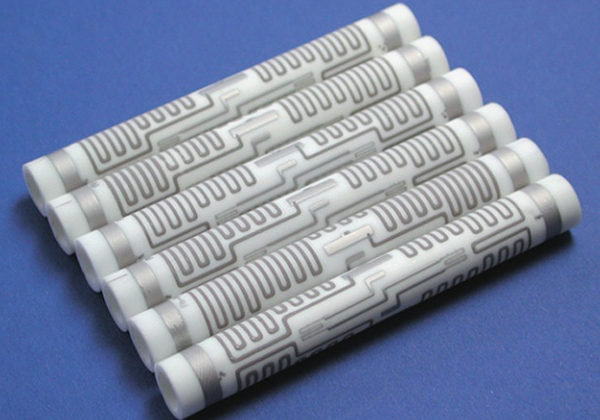

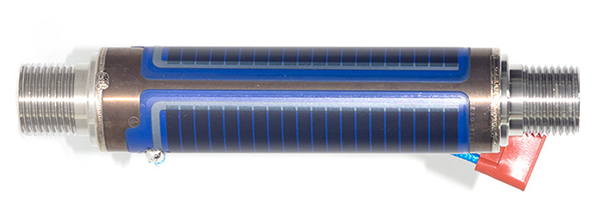

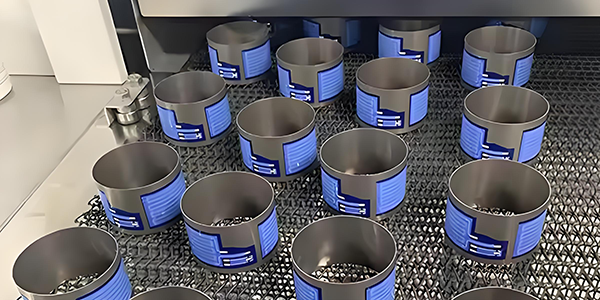

Thick Film Tubular Heaters

Thick Film Tubular Heaters, also called Thick Film Cylindrical Heaters, are high-efficiency heating devices that use tubular stainless steel or ceramic as the substrate, applying thick film heating technology to precisely coat the surface with conductive materials, heating resistors, and insulating materials, which allows them to convert electrical energy into thermal energy through the Joule heating effect to provide stable and precise heating, achieve high thermal efficiency at low power, ensure even heat distribution, reduce the risk of overheating, and deliver durable performance.

Thick Film Tubular Heaters have several standout characteristics. First, their stainless steel or ceramic substrate materials provide strong durability in high-temperature and corrosive environments. The thick film technology enables excellent thermal efficiency, ensuring that most of the input energy is converted into radiant heat (up to 92%). They typically operate within a temperature range of 300°C to 700°C, emitting infrared wavelengths that are ideal for various applications, especially where temperature control and energy efficiency are critical. Additionally, the design of these heaters helps prevent localized overheating, ensuring uniform heating.

Thick Film Cylindrical Heaters are widely used in multiple fields that require precise heating. In the food industry, they are employed for heating and baking bread, warming food, and maintaining temperature. They are also used in coating curing processes and plastic softening or welding. In the medical field, these heaters are found in heating systems and experimental equipment. In aerospace and automotive industries, Thick Film Tubular Heaters are ideal for high-demand environments due to their efficiency and reliability. By providing a stable heat source, they meet the needs of various industrial and commercial applications.

Types of Thick Film Tubular Heaters :

● Straight Tubular Heaters: Straight tubes with a uniform resistive coating along their length, suitable for heating applications requiring uniform heat distribution.

● U-Shaped Tubular Heaters: Tubular thick film heaters bent into a U-shape, ideal for applications where space constraints or specific heating patterns are required.

● Finned Tubular Heaters: Tubular thick film heaters with fins attached to increase the surface area for improved heat transfer, commonly used in air heating applications.

● Immersion Tubular Heaters: Designed to be immersed in liquids or gases for heating purposes, featuring a sealed construction to prevent corrosion.

Features of Thick Film Tubular Heaters :

● High Thermal Efficiency: Thick Film Tubular Heaters are designed to convert a large portion of electrical energy into thermal energy, with up to 92% of input energy being emitted as radiant heat, ensuring effective heat transfer and reducing energy waste.

● Durable Construction: Made with durable materials such as stainless steel or ceramic, these heaters offer excellent resistance to high temperatures, corrosion, and mechanical stress, ensuring long-lasting performance in harsh environments.

● Uniform Heat Distribution: The precise application of thick film technology ensures uniform heat distribution across the heating surface, minimizing hot spots and ensuring more efficient and consistent heating.

● Compact and Versatile Design: The tubular shape of the heater allows for compact installation and easy integration into various systems and applications, including industrial, medical, and food-related processes.

● Temperature Control: Thick Film Tubular Heaters operate within a wide temperature range, typically from 300°C to 700°C, making them adaptable to various heating requirements with precise temperature control.

● Energy Efficiency: With their efficient radiant heat emission, these heaters optimize energy use, reducing electricity consumption while providing consistent and reliable heating performance.

● Fast Response Time: Due to their advanced construction and material properties, Thick Film Tubular Heaters can heat up quickly and provide rapid response times, making them ideal for applications requiring quick and precise temperature changes.

Applications of Thick Film Cylindrical Heaters :

● Food Industry: Thick Film Cylindrical Heaters are commonly used in the food industry for applications like baking, toasting, caramelizing, and warming foods. Their ability to emit infrared radiation makes them ideal for achieving uniform heat distribution, ensuring consistent food quality.

● Coating Curing: These heaters are widely used in the curing process of coatings, including paint and varnish. The precise and efficient heat generated by Thick Film Cylindrical Heaters helps in speeding up the curing process, ensuring a high-quality finish.

● Plastic Processing: In the plastic industry, Thick Film Cylindrical Heaters are used for softening and welding plastics. Their ability to provide controlled, even heat makes them perfect for molding, shaping, and joining plastic materials in various manufacturing processes.

● Medical Devices: These heaters are applied in the medical field, especially in diagnostic and therapeutic devices, where precise and consistent heating is required. They are used for heating medical equipment or fluids and maintaining the necessary temperature in various healthcare applications.

● Industrial Heating: Thick Film Cylindrical Heaters are extensively used in industrial heating applications, including heating gases, liquids, or solids in a wide range of processes, from temperature control in manufacturing to process heating in energy-intensive industries.

● Automotive and Aerospace: Due to their high efficiency and reliability, these heaters are found in automotive and aerospace industries, where they are used for de-icing, heating, and maintaining temperature in critical systems under extreme conditions.

● Laboratory and Research: In laboratory settings, Thick Film Cylindrical Heaters are employed for heating samples, reactors, and specialized equipment. Their ability to deliver precise and controlled heat makes them essential for scientific research and testing procedures.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters