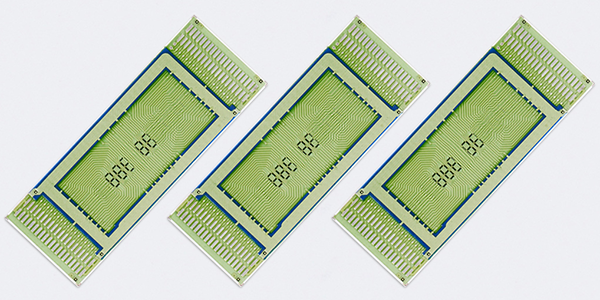

Thermosensitive-Ceramic Heating Elements

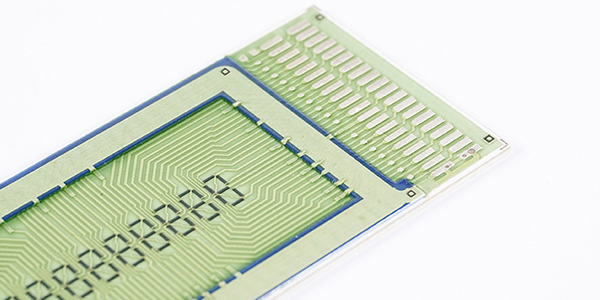

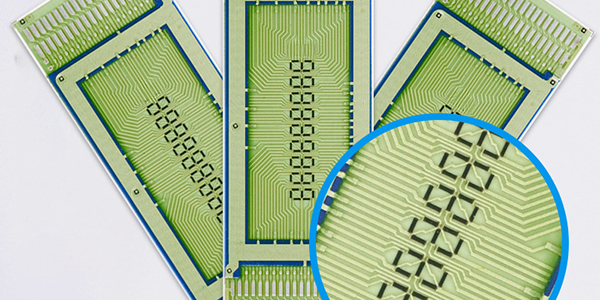

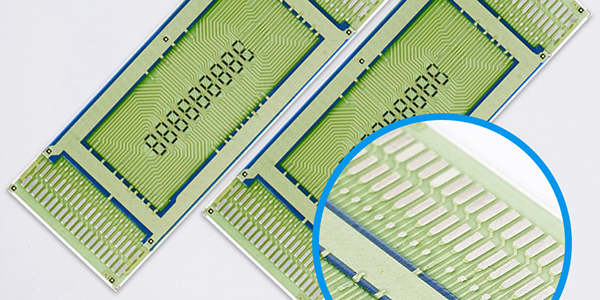

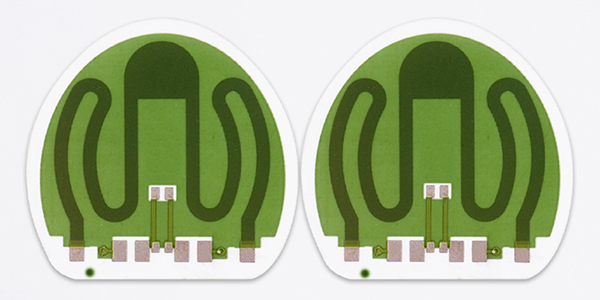

Thermosensitive-Ceramic Heating Elements, also referred to as Thermosensitive-Ceramic Thick Film Circuits, are high-temperature, highly reliable hybrid integrated circuits made by combining ceramic substrates with thick-film technology through advanced printing, high-temperature sintering, and laser trimming techniques that enable rapid temperature response and uniform heating, meeting the high-precision requirements of thermosensitive components.

Thermosensitive-Ceramic Heating Elements boast excellent temperature control capability and stability as their main features, with the ceramic substrate offering good thermal conductivity and high-temperature resistance, while the thick-film printing technique ensures the even distribution of heating elements, effectively preventing hot spots; furthermore, the thick-film technology allows the heating plate to handle higher current densities, providing more efficient heating, and the corrosion resistance of the ceramic substrate enhances the durability of the heating plate, making it suitable for use in a variety of complex environments.

Thermosensitive-Ceramic Thick Film Circuits are widely used in various thermosensitive devices, particularly in fields such as lasers, CNC systems, and temperature sensors. Due to their ability to heat quickly and maintain a stable temperature, they are commonly used in applications that require precise temperature control, such as in laser equipment and high-precision thermosensitive sensors. Their excellent performance makes them essential in fields like precision instruments, industrial automation, and medical devices, effectively supporting the efficient operation and long-term stability of the equipment.

Features of Thermosensitive-Ceramic Heating Elements :

● Excellent Temperature Control: Thermosensitive-Ceramic Heating Elements are designed to provide precise temperature control. They are ideal for applications requiring stable and consistent heat distribution.

● Good Thermal Conductivity: The ceramic substrate has high thermal conductivity, allowing for efficient heat transfer and preventing heat buildup, which enhances overall system performance.

● High-Temperature Resistance: Ceramic materials used in these heating elements are resistant to high temperatures, making them suitable for demanding environments where standard materials might fail.

● Even Heat Distribution: Thanks to the advanced thick-film printing technique, the heating elements are evenly distributed across the ceramic surface. This helps prevent hot spots, ensuring uniform heating across the PCB.

● Efficient Heating: The thick-film technology supports high current densities, allowing for faster and more efficient heating. This feature is critical for applications requiring quick temperature adjustments.

● Durability and Corrosion Resistance: The ceramic substrate offers strong resistance to corrosion, ensuring the heating element remains reliable over time, even in harsh or chemically aggressive environments.

● Versatile Applications: Thermosensitive-Ceramic Heating Elements are widely used in various industries, including electronics, medical devices, automotive, and industrial automation, where precise temperature control and durability are essential.

Stable Performance in Complex Environments: The combination of high thermal conductivity, corrosion resistance, and thermal stability ensures that these Thermosensitive-Ceramic Heating Elements perform reliably in complex and challenging environments.

Applications of Thermosensitive-Ceramic Heating Elements :

Thermosensitive-Ceramic Heating Elements are widely used across various industries due to their excellent temperature control properties, good thermal conductivity, and high-temperature resistance. Below are some typical application areas:

1, Electronic Devices:

● LED Lighting: Thermosensitive-Ceramic Heating Elements are used in LED lighting systems for heat dissipation and temperature control, ensuring that LEDs do not overheat during high-efficiency operation and extending their lifespan.

● Smartphones and Laptops: Used for efficient heat dissipation to prevent devices from overheating, especially during high-speed processing or heavy load operations.

2, Automotive Industry:

● Electric Vehicles: In battery packs, electronic control units (ECUs), and other critical components, Thermosensitive-Ceramic Heating Elements can regulate temperature to prevent performance degradation or component failure due to high temperatures.

● Automotive Seat Heating: Thermosensitive-Ceramic Heating Elements are integrated into seat heating systems to provide uniform and comfortable heating.

3, Medical Devices:

● Temperature Regulation Devices: Used in medical equipment to precisely control patient temperature, such as in temperature-controlled mattresses or therapeutic devices.

● Heating Therapy Equipment: In physical therapy devices, they provide a stable heat source to help patients relieve pain or accelerate recovery.

4, Industrial Automation:

● Industrial Heating Systems: Used for temperature control in high-temperature equipment and processes, ensuring that devices operate at optimal temperatures to improve efficiency and product quality.

● Sensor Heating: Used to heat environmental sensors, pressure sensors, and other devices to ensure their normal operation in low-temperature environments.

5, Aerospace:

● Spacecraft Temperature Control: Thermosensitive-Ceramic Heating Elements are used in spacecraft to control the temperature of sensitive electronic components, preventing extreme temperatures from affecting device performance.

● Aircraft Cabin Heating: They are used to provide a comfortable cabin temperature for passengers, especially in cold high-altitude environments.

6, Home Appliances:

● Electric Kettles and Heaters: Thermosensitive-Ceramic Heating Elements are widely used in appliances like electric kettles and space heaters to ensure efficient heating and safety.

● Refrigerators: Used to provide additional heating functions in cold environments to prevent freezing and ensure optimal performance.

7, New Energy Sector:

● Solar Energy Equipment: In solar water heaters or solar power generation systems, Thermosensitive-Ceramic Heating Elements help maintain a stable operating temperature, improving system efficiency.

● Energy Storage Systems: Used in thermal energy storage or battery management systems, temperature control helps enhance energy conversion and storage efficiency.

The wide applications of Thermosensitive-Ceramic Heating Elements highlight their advantages in precise temperature control, heat dissipation management, and high-temperature tolerance. Whether in consumer electronics, automotive, medical, industrial automation, or energy and aerospace sectors, these heating elements provide stable and reliable temperature control solutions to ensure the efficient and safe operation of devices.

For more information, Please refer to Thick Film Heating Elements.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters