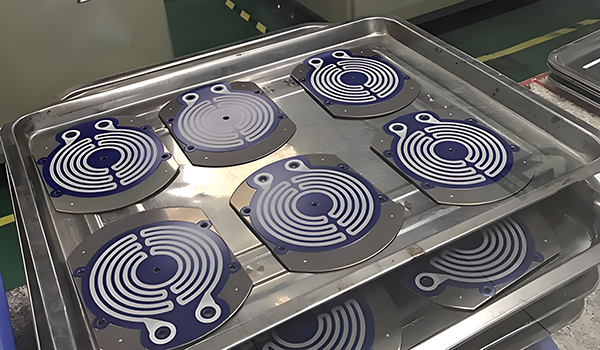

Custom Thick Film Heating Elements

Custom Thick Film Heating Elements are a highly efficient heating solution widely used in industries, home appliances, and medical devices, employing thick film technology that operates on the principle of Joule heating, where electrical energy is converted into heat to achieve the desired heating effect, typically using ceramic or stainless steel substrates that offer exceptional heat resistance and stability, ensuring reliable performance even under high-temperature conditions.

Custom Thick Film Heating Elements are known for their high heat conversion efficiency and uniform heat distribution. When electrical current passes through the resistive layer, electrical energy is transformed into heat, ensuring that the entire heating surface has an even temperature distribution, which enhances heating performance. These elements also feature rapid response times and short heating periods, reaching the target temperature quickly while saving energy. Furthermore, they have a long lifespan and can operate stably in harsh environments, reducing maintenance frequency and costs.

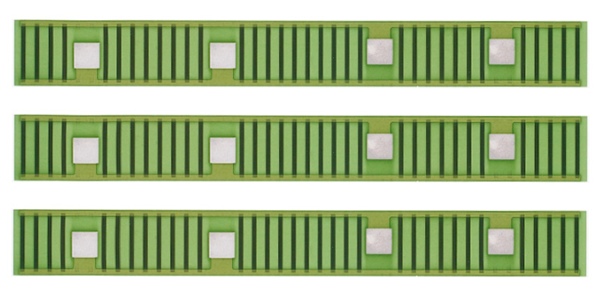

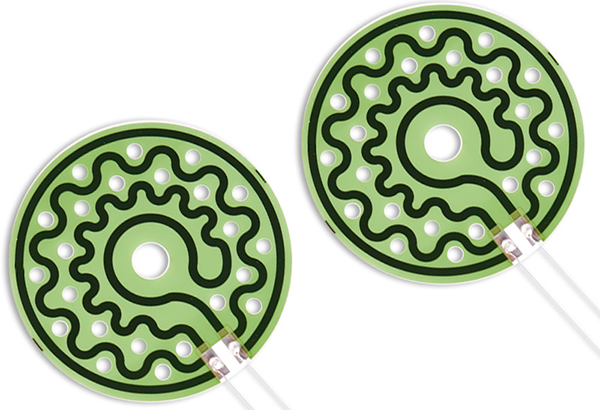

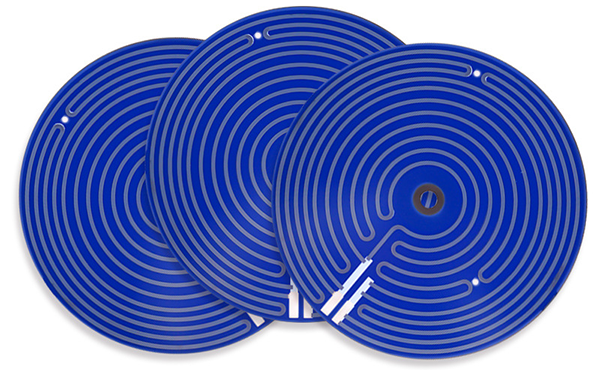

Custom Thick Film Heating Elements also offer significant design flexibility. Depending on customer requirements, heating elements can be customized in various sizes, shapes, and power ratings to meet diverse application needs. From high-temperature heating to precise temperature control, custom designs ensure optimized performance, enhancing overall operational efficiency. Therefore, thick film heating elements have broad market potential across a range of specialized applications, providing extensive design possibilities and a variety of choices.

Substrate Selection of Custom Thick Film Heating Elements :

The substrate of Custom Thick Film Heating Element forms the foundation of its structure, with commonly used substrates being ceramics and stainless steel.

● Ceramic Heaters: Ceramic substrates possess good thermal stability and electrical insulation properties, able to withstand high-temperature environments while maintaining stable electrical performance. Additionally, ceramic materials are hard, wear-resistant, and suitable for heaters requiring long-term stable operation.

● Stainless Steel Heaters: Stainless steel substrates are widely used due to their excellent corrosion resistance and strength. They can maintain performance in various harsh environments, are easy to shape into various forms, and are suitable for applications requiring high mechanical strength.

Heating Composition of Custom Thick Film Heating Elements :

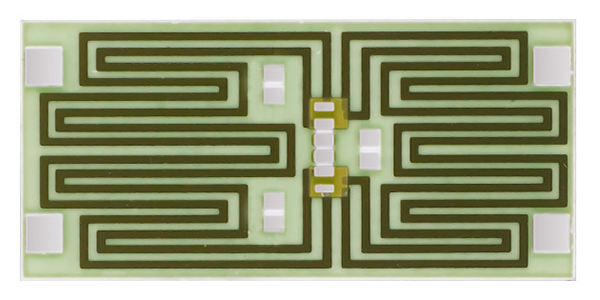

The heating conductor is the core component of a thick film heater, primarily composed of a conductive material, resistive material, dielectric material, and insulating material.

● Conductive Material: Responsible for transferring electrical current, commonly used materials include silver, copper, etc., known for their excellent electrical and thermal conductivity to effectively convert electrical energy into heat.

● Resistive Material: The main heating element, the material selection significantly impacts heating efficiency and lifespan. Common resistive materials include nickel-chromium alloys, iron-chromium alloys, which can work stably for extended periods, providing continuous heat output.

● Dielectric Material: Used for circuit isolation ensuring the safe operation of the heater. Typically possessing good electrical insulation properties to prevent current leakage and ensure safety during use.

● Insulating Material: Used to isolate various parts of the heater, preventing short circuits while also serving as a support structure to enhance overall heater strength.

Production Process of Custom Thick Film Heating Elements :

● Design and Specification: The first step is to design the heater based on the customer's specifications, which includes the size, shape, power output, and any other specific requirements.

● Substrate Preparation: A substrate, often made of a material like Ceramic, PI, PET, or Stainless Steel , is prepared. It serves as the base for the heater.

● Screen Printing: Using a screen printing process, conductive inks are applied to the substrate in the pattern of the heating element. This is done through a stencil that has the design of the heating element.

● Drying and Curing: The ink is then dried and cured, which solidifies the conductive path on the substrate.

● Resistor Integration: A resistance element is integrated into the design to control the amount of heat produced.

● Layering: Additional layers of inks may be applied for insulation or protection. These are also dried and cured.

● Testing: Each heater is tested for electrical continuity and heat output to ensure it meets the specifications.

● Assembly: The individual heaters are assembled into the final product, which may include attaching them to a frame or integrating them into a larger system.

Heating Principle of Custom Thick Film Heating Elements :

● The heating principle of Custom Thick Film Heating Element is based on the joule heating effect, where electrical energy is converted into heat as current passes through the resistive material. Precise control of the resistance value of the resistive material and the current passing through it allows for adjusting the heater's output power, enabling precise temperature control.

Advantages of Custom Thick Film Heating Elements :

● Efficiency: Optimized design of the resistive and conductive materials allows the Custom Thick Film Heating Element to efficiently convert electrical energy into heat, reducing energy losses.

● Uniform Heating: Ensures even surface temperature distribution, eliminating issues of local overheating or inadequate heating.

● Rapid Response: Capable of quickly responding to temperature changes, achieving rapid heating and cooling.

● Long Lifespan: High-quality materials and precise craftsmanship ensure long-term stable operation and extended lifespan of the heater.

● Design Flexibility: The shape and size of the heater can be customized according to specific application requirements, adapting to various installation environments.

Applications of Custom Thick Film Heating Elements :

● New Energy Vehicles: In new energy vehicles, Custom Thick Film Heating Elements can be used for battery pack heating and cabin air conditioning heating, ensuring vehicle performance and comfort in low-temperature environments.

● Medical Equipment: In medical devices, Custom Thick Film Heating Elements can be used for precise temperature control, such as in applications within constant temperature boxes, incubators, etc.

● Industrial Heating: In industrial production processes, Custom Thick Film Heating Elements can be used for various heating and insulation processes, improving production efficiency and product quality.

● Household Appliances: In household appliances like water heaters, ovens, etc., Custom Thick Film Heating Elements provide efficient and safe heating solutions.

Design Considerations for Custom Thick Film Heating Elements :

When designing Custom Thick Film Heating Elements, several key factors must be considered to ensure optimal performance, safety, and reliability. Below is a comprehensive overview of these design considerations:

● Substrate Selection: Choose an appropriate substrate material based on thermal conductivity, mechanical strength, and compatibility with the target application. Common substrates include ceramics and stainless steel.

● Heating Element Design: Design the heating element layout and pattern to achieve the desired heating profile while optimizing energy efficiency and uniformity of heating. Consider factors such as conductor width, spacing, and configuration.

● Temperature Control: Incorporate temperature sensing and control elements into the heater design to maintain precise temperature control within the desired range. Choose appropriate temperature sensors (e.g., thermistors, thermocouples) and control algorithms for accurate temperature regulation.

● Safety Features: Implement safety features such as overheat protection, current limiting, and short circuit protection to prevent damage to the heater and ensure user safety. Ensure compliance with relevant safety standards and regulations.

● Environmental Considerations: Evaluate the operating environment for factors such as humidity, corrosive gases, vibration, and mechanical stress, and design the heater to withstand these conditions for reliable long-term performance.

● Mounting and Integration: Consider how the heater will be mounted and integrated into the overall system design. Design mounting features and electrical connections to facilitate easy installation and maintenance.

● Electrical Design: Calculate the electrical parameters of the heater, including voltage, current, power density, and resistance, to ensure compatibility with the power source and electrical system requirements.

Why Deed to Custom Thick Film Heating Elements ?

● Precision and Accuracy: Custom Thick Film Heating Elements can be designed to meet exact specifications regarding power output, temperature range, and response time, ensuring they perform accurately for their intended use.

● Application-Specific Requirements: Different applications may require heaters with unique shapes, sizes, or configurations. Customization allows for the creation of heaters that fit perfectly into the application's design, whether it's for a small device or a large industrial process.

● Material Compatibility: By customizing the material used in the thick film heater, it's possible to ensure compatibility with the surrounding components and the environment in which the heater will operate, enhancing the longevity and reliability of the system.

● Efficiency and Energy Use: Custom Thick Film Heating Elements can be optimized for energy efficiency, reducing power consumption and operating costs without compromising performance.

● Reliability and Durability: Customized heaters are often built to be more robust and reliable, with the ability to withstand harsh conditions or specific operational demands that off-the-shelf products might not be able to manage.

● Thermal Performance: Tailoring the design of the thick film heater allows for precise control over thermal performance characteristics, such as uniformity of heat distribution and heat-up times, which are critical in many applications.

● Integration with Control Systems: Customized heaters can be integrated with control systems for precise temperature management, which is particularly important in applications like medical devices or precision manufacturing processes.

● Cost-Effectiveness: While there may be an initial investment in customization, it can lead to cost savings over time by reducing the need for modifications, replacements, and optimizing manufacturing processes.

● Innovation: Customization enables the development of innovative solutions that may not be possible with standard products, allowing companies to stay ahead in a competitive market.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters