Flexible Heating Elements

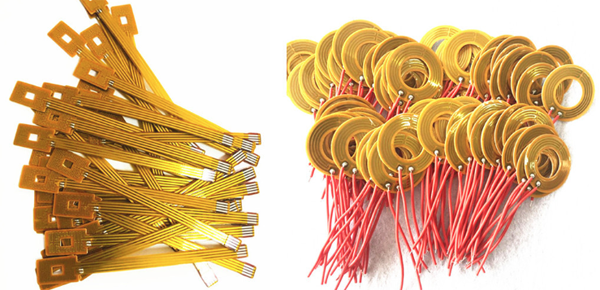

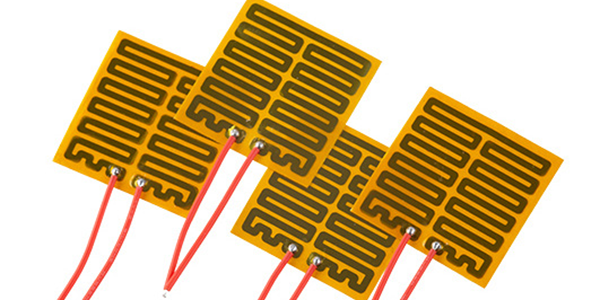

Flexible Heating Elements, or called Flex Heating Elements, are versatile and adaptable heating solutions designed to conform to various shapes and surfaces, made from thin, flexible materials that can be easily shaped and integrated into a wide range of applications, typically consisting of a heating wire or conductive material embedded within a flexible substrate to allow efficient heat distribution across curved or irregular surfaces, making them ideal for spaces where traditional rigid heating elements may not be suitable.

Flexible Heating Elements are commonly used in industries such as automotive, aerospace, medical devices, and consumer electronics. Their ability to be customized to different sizes and forms makes them perfect for heating areas that require uniform temperature distribution, such as seat warmers in vehicles or heating pads for medical treatments. Additionally, they are lightweight and easy to install, offering significant space-saving advantages in compact designs and environments with limited space.

Flexible Heating Elements offer excellent efficiency and durability, capable of providing consistent heat over extended periods without compromising performance. They are also energy-efficient, as they can be tailored to specific heating requirements, minimizing energy waste. With features like fast heating, flexibility, and durability, these heating elements are becoming increasingly popular for both industrial and personal use, providing a reliable and cost-effective solution for various heating needs.

Features of Flexible Heating Elements :

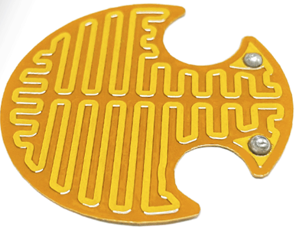

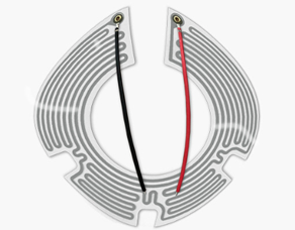

● Flexibility: The primary feature is their ability to bend and conform to various shapes without losing electrical or heating integrity, making them suitable for irregular or curved surfaces.

● Customizable Size and Shape: Flexible Heating Elements can be cut and shaped to fit specific dimensions, allowing for precise application to the area that requires heating.

● Even Heat Distribution: Flexible heating elements are engineered to provide uniform heat across their surface, which is essential for applications that require consistent temperature control.

● Durability: Despite their flexibility, these heating elements are often made from robust materials that can withstand regular use and resist wear and tear.

● Adhesive Backing: Many flexible heaters come with an adhesive backing for easy and secure installation onto a substrate.

● Energy Efficiency: Flexible Heating Elements are designed to convert electrical energy into heat efficiently, minimizing energy loss and providing effective heating with lower power consumption.

● Safety: Flexible heating elements often incorporate safety features such as thermal cutoff switches to prevent overheating and materials that are self-extinguishing or fire-resistant.

● Low Profile: Flexible Heating Elements are thin and unobtrusive, making them ideal for applications where space is limited.

● Silence: Unlike mechanical heating systems, flexible heating elements operate silently, which is beneficial for noise-sensitive environments.

● Versatility: Flexible Heating Elements can be used in a wide range of applications, from personal items like heated clothing to industrial machinery and medical equipment.

● Quick Response Time: Flexible heating elements can reach the desired temperature quickly, which is advantageous for applications that require rapid heating.

● Compatibility with Controls: Many models are compatible with external control systems, including thermostats and timers, for precise temperature regulation.

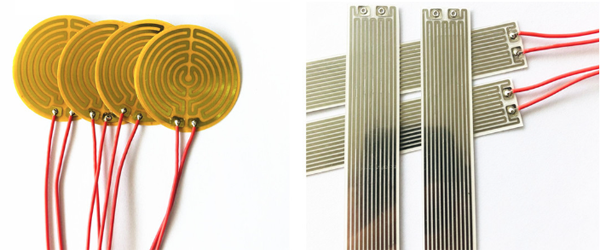

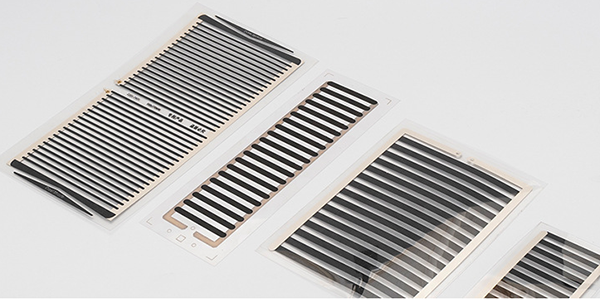

Types of Flexible Heating Elements :

There are two main types of Flexible Heating Elements based on the substrate material and manufacturing process:

|

|

● Polyimide Heating Elements: These elements are made using polyimide films as the base material. Polyimide Heating Elements offer excellent thermal stability, chemical resistance, and flexibility, making them suitable for high-temperature applications.

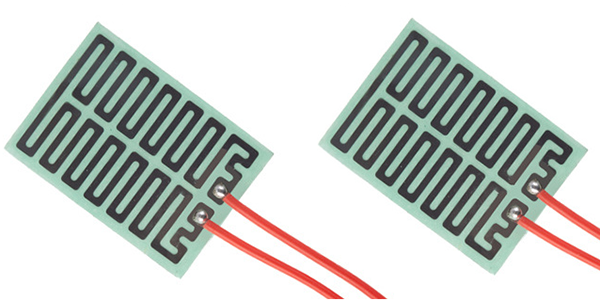

● Polyester Heating Elements: Polyester Heating Elements are constructed using polyester films. They are known for their cost-effectiveness, durability, and flexibility, making them a popular choice for applications where lower temperatures are required.

Polyimide VS Polyester Heating Elements :

● Temperature Resistance: Polyimide heating elements are designed to endure much higher temperatures, often up to 500°F (260°C), which makes them ideal for high-heat applications. Polyester heating elements, on the other hand, are better suited for lower temperature applications, typically up to 250°F (120°C).

● Durability and Lifespan: Polyimide heaters are more durable and tend to have a longer operational lifespan, even when used continuously at high temperatures. Polyester heaters, while versatile, may have a shorter lifespan in high-temperature environments.

● Flexibility and Conformability: Both polyimide and polyester heaters can be made flexible, allowing them to be bent and shaped to fit various surfaces and objects. This feature makes them suitable for a wide array of applications where a custom fit is necessary.

● Cost: Polyester heaters are generally more cost-effective due to the lower cost of the material and the simpler manufacturing process, making them a popular choice for applications where high-temperature resistance is not a primary concern.

● Chemical and Environmental Resistance: Polyimide heaters have excellent resistance to chemicals, moisture, and radiation, which is particularly important in harsh or sensitive environments. Polyester heaters, while also resistant, may not perform as well in extreme conditions.

● Electrical Properties: Polyester materials are known for their excellent electro-insulating properties, making them safe for use in electrical applications. Polyimide also offers good electrical insulation, but its primary advantage lies in its high-temperature stability.

● Applications: Polyimide heaters are often used in aerospace, medical equipment, and high-temperature industrial processes. Polyester heaters find applications in textiles, automotive, and home appliances where lower temperatures are required.

● Safety and Anti-Static Properties: Polyester has good anti-static properties and can be processed to enhance these characteristics, making it suitable for electronics and textiles. Polyimide, while not primarily known for these properties, is used in safety-critical applications due to its reliability at high temperatures.

Applications of Flex Heating Elements :

1, Medical and Healthcare:

● Patient warming systems in hospitals and clinics.

● Temperature regulation for medical equipment and devices.

2, Automotive:

● Windshield and window defrosting systems.

● Seat heaters for increased passenger comfort.

3, Aerospace:

● De-icing systems for aircraft wings and engine inlets.

● Temperature maintenance for sensitive electronics and avionics.

4, Domestic and Residential:

● Underfloor heating systems for homes.

● Heated blankets and clothing for personal comfort.

5, Commercial and Industrial:

● Heating pipes and tanks to prevent freezing and maintain fluid flow.

● Process heating in manufacturing for temperature-sensitive materials.

6, Outdoor and Recreational:

● Heating for tents, gazebos, and recreational vehicles (RVs).

● Snow melting systems for walkways and driveways.

7, Packaging:

● Temperature maintenance in packaging for temperature-sensitive goods during shipping.

8, Footwear and Apparel:

● Heated insoles for shoes and boots.

● Warming elements in gloves and other clothing.

9, Electronics:

● Providing heat to prevent condensation and maintain operational temperatures in outdoor electronics.

10, Military and Field Operations:

● Heated clothing and gear for soldiers in extreme weather conditions.

● Equipment warming to ensure functionality in the field.

11, Aquatics and Terrariums:

● Heating elements for aquariums and reptile enclosures to maintain a stable environment.

12, Beauty and Spa Industry:

● Warming beds and seats in salons and spas.

● Heating elements for beauty equipment.

13, Food and Beverage:

● Keeping food warm in display cases and serving areas.

● Thawing and proofing equipment in commercial kitchens.

14, Office and Workspace:

● Providing localized heating for increased comfort in offices and workspaces.

15, Sports Equipment:

● Heated grips for bicycles, motorcycles, and other sports equipment.

For more information, Please refer to Thick Film Heating Elements.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters