Thick Film Heating Solution

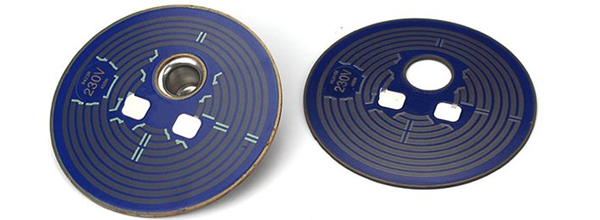

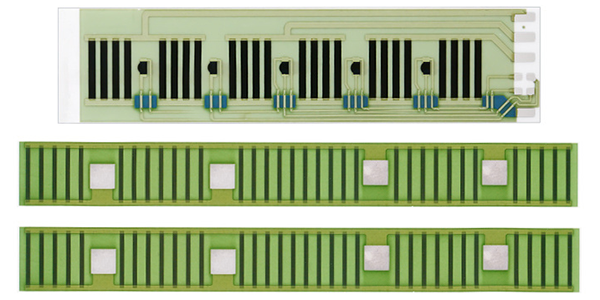

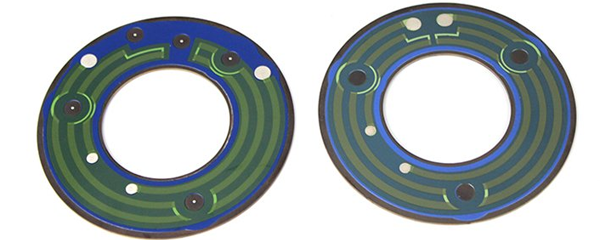

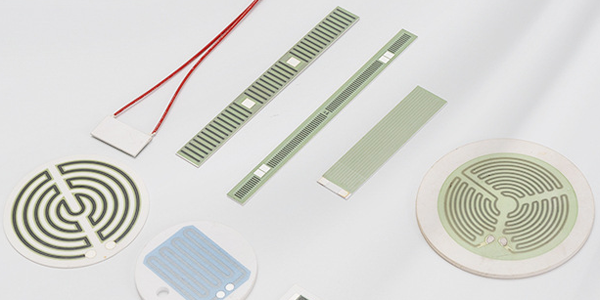

Thick Film Heating Solutions, also known as Thick Film Heating Technologies, are advanced and customizable heating technologies that precisely coat heating materials onto various substrates (such as ceramics or metals) based on customer's specifications (such as heater dimensions, heating patterns, temperature, power, and input voltage) to create highly efficient, precise, and reliable heating elements. Compared to traditional heating elements, thick film heaters feature smaller sizes and higher power densities, enabling them to provide stronger heating capabilities in confined spaces, making them suitable for a wide range of complex applications.

Thick Film Heating Solutions are widely applied in industries such as automotive, medical equipment, electronics, and home appliances. They not only offer efficient heating capabilities but also have advantages such as long lifespans, high-temperature resistance, and corrosion resistance. Additionally, thick film heaters can heat up in a very short time, and through precise control of current and power output, they can meet the demands for temperature accuracy and stability in various fields.

Thick Film Heating Solutions are expected to continue evolving with continuous technological advancements, moving toward higher efficiency, more intelligent control systems, and more environmentally friendly materials. In the future, features like adaptive temperature control and remote monitoring are expected to emerge, further enhancing their application potential across various industrial fields while reducing energy consumption and improving system reliability.

Why Panda PCB For Thick Film Heating Solutions ?

At PANDA PCB, we specialize in providing cutting-edge thick film heating solutions that offer high power density, compact size, high pressure resistance, minimal power loss, rapid thermal response, anti-scaling properties, and an impressive heat conversion rate of up to 96%.

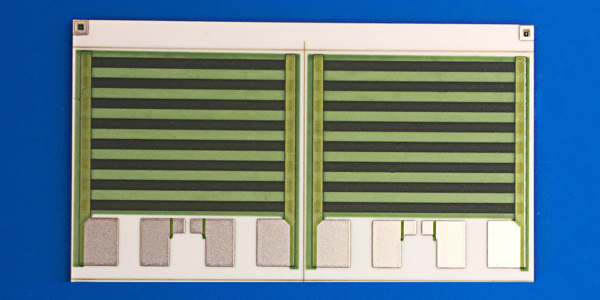

Our portfolio currently features two main types of thick film heating elements:

● Stainless Steel-Thick Film Heating Elements

● Ceramic-Thick Film Heating Elements.

Our team of skilled engineers excels at developing innovative thick film heating solutions tailored to meet the diverse needs of our clients across various industries. From consumer products to medical devices requiring precise and rapid heating, to commercial food equipment necessitating uniformly heated surfaces, we deliver customized solutions that exceed expectations and drive operational efficiency.

At PANDA PCB, we are committed to pushing the boundaries of thick film heating technology, ensuring that our clients benefit from reliable, efficient, and advanced heating solutions that enhance performance and productivity across a wide range of applications.

Benefits of Thick Film Heating Solutions :

1, Quick and Efficient Heating:

Thick film heating solutions excel in rapid heat generation, allowing them to achieve target temperatures swiftly compared to traditional heaters. This quick response time not only enhances operational efficiency but also ensures a comfortable and timely heating experience. Moreover, the ability of ceramic or stainless steel substrates to absorb and retain heat efficiently contributes to energy savings and reduced operating costs.

2, Energy Efficiency and Environmental Sustainability:

With their ability to heat up rapidly and maintain desired temperatures effectively, thick film heating elements are highly energy-efficient. By utilizing electric current efficiently and minimizing power consumption, these heating solutions offer a greener alternative to traditional heating methods that rely on fossil fuels. The energy stored in the substrates further enhances energy efficiency by optimizing heat retention and distribution, ultimately reducing environmental impact and promoting sustainable practices.

3, Portability, Lightweight Design, and Safety Features:

One of the key advantages of thick film heating solutions is their portability and lightweight construction, making them ideal for versatile applications across different settings. Whether used at home or in commercial spaces, these heaters can be easily transported and repositioned to provide targeted heating where needed. Additionally, safety features such as cool-touch housing and overheat protection enhance user safety and prevent potential hazards associated with overheating.

4, Quiet Operation and Rapid Cooling:

In addition to their efficiency and safety features, thick film heating solutions operate quietly, creating a comfortable and noise-free environment. Unlike conventional heaters that may produce disruptive sounds during operation, thick film heating elements offer silent performance, making them suitable for various indoor settings. Furthermore, these heaters cool down quickly once deactivated, enhancing their productivity and allowing for efficient use of energy resources.

Applications of Thick Film Heating Solutions :

1, Home Appliances: Thick film heating solutions are commonly used in home appliances such as electric ovens, toasters, coffee makers, and electric kettles due to their rapid heating capabilities and energy efficiency.

2, Medical Devices: These heating solutions find application in medical equipment such as incubators, warming plates, and fluid heaters, where precise and reliable heating is essential for patient care.

3, Industrial Equipment: Thick film heating elements are utilized in industrial processes for applications like plastics welding, semiconductor manufacturing, and food processing, where consistent and high-performance heating is required.

4, Automotive Industry: They are employed in automotive systems for applications like heated seats, HVAC systems, and fluid heating in vehicles, providing efficient and reliable heating solutions.

5, Aerospace: In the aerospace industry, thick film heating solutions are used in areas such as de-icing systems and environmental control systems in aircraft to ensure optimal performance in extreme conditions.

6, Energy Sector: These heating solutions are applied in renewable energy systems, battery heating, and fuel cell technology, contributing to the efficient operation of energy-related equipment.

7, Consumer Electronics: Thin and compact design makes them suitable for consumer electronics such as hair styling tools, hand dryers, and heated displays, enhancing user experience with quick and responsive heating.

8, Food and Beverage Industry: Thick film heating elements are utilized in commercial kitchen equipment, food processing machinery, and beverage dispensers for efficient and hygienic heating applications.

Thin Film VS Thick Film Heating Technology :

1, Application Method:

● Thick film resistors are created by screen printing a paste made from a mixture of glass and metal oxides onto a substrate and then firing it at high temperatures, which results in a glass-like layer.

● Thin film resistors involve a vacuum deposition process where a metallic film is applied onto an insulating substrate.

2, Material Composition:

● Thick film technology uses a paste that is a mixture of a binder (glassy frit), a carrier, and metal oxides such as those of ruthenium, iridium, and rhenium.

● Thin film technology typically uses an alloy like Nickel and Chromium (Nichrome) for the resistive layer.

3, Tolerance and Temperature Coefficients:

● Thick film resistors generally have larger tolerances (±1 - ±5%) and temperature coefficients (±50 - ±200 ppm/°C) compared to thin film resistors.

● Thin film resistors offer better precision with lower tolerances (±0.1 - ±2%) and temperature coefficients (±5 - ±50 ppm/°C).

4, Performance Characteristics:

● Thin film resistors are known for lower noise, lower parasitic inductance and capacitance, making them suitable for high-precision and high-frequency applications.

● Thick film technology, while generally less precise, is more resistant to moisture due to its glass-like composition and can handle more power and higher surge conditions.

5, Applications:

● Thin film heating solutions are used in precision applications where high tolerance and stability are required, such as in medical equipment, audio installations, and precision controls.

● Thick film heating elements are more common in general applications where precision is less critical and cost is a consideration, such as in consumer electronics and everyday devices.

6, Cost:

● Thin film technology typically comes with a higher cost due to its precision and performance.

● Thick film technology is usually more cost-effective, making it a popular choice for a wide range of applications where high precision is not a necessity.

7, Substrate Material:

● Both technologies can use similar substrate materials like ceramics, stainless steel, and glass, but the choice may depend on the specific requirements of the application and the properties of the resistive pastes and conductor materials.

For more information, Please refer to Thick Film Heating Elements.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

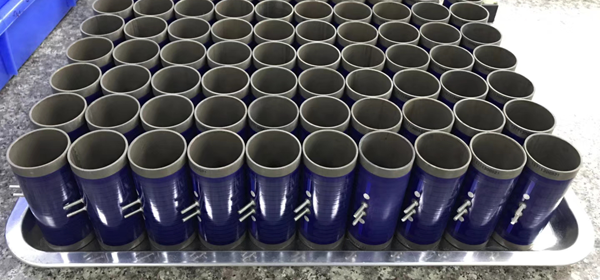

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters