Polyimide Heaters (PI Heaters)

Polyimide Heaters, also known as PI Heaters, are electric heating elements constructed using polyimide film as the substrate material. These thin, lightweight, and flexible heaters are engineered to deliver uniform and efficient heat distribution for a wide range of industrial, commercial, and consumer applications, offering exceptional versatility in heating solutions.

Polyimide Heaters are ideal for flexible heating applications in environments with space and weight constraints, or where exposure to extreme conditions such as vacuum, oil, or chemicals is expected. They are particularly suited for applications that require low outgassing in vacuum environments, as well as resistance to radiation, fungus, and various chemicals, making them an optimal choice for challenging operating conditions.

Polyimide Heaters utilize polyimide film, which provides excellent thermal stability, superior chemical resistance, and outstanding mechanical strength, ensuring durability in demanding environments. Manufactured using advanced thin-film technology, these heaters allow for precise control over heat distribution and temperature gradients, ensuring optimal performance and energy efficiency.

PI Heaters can be custom-designed to meet specific requirements in terms of shape, size, and integration with additional components such as sensors and insulation. They are widely used in industries such as aerospace, medical devices, automotive, electronics, and food processing, where flexibility, durability, and high-performance heating are critical to the success of the application.

Main Features of Polyimide Heaters :

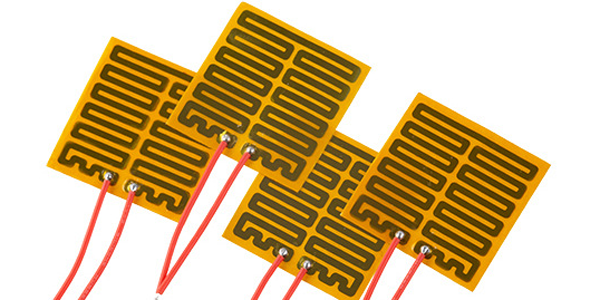

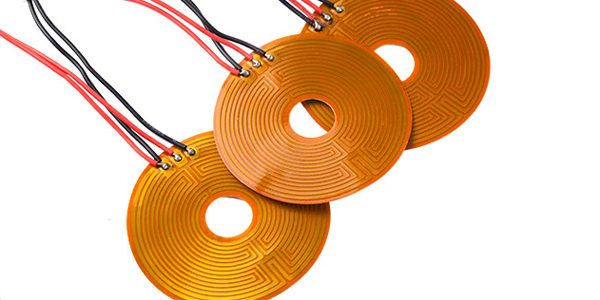

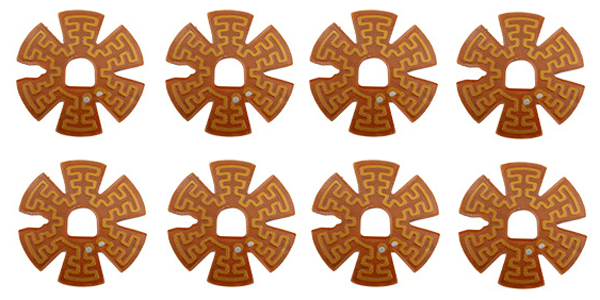

1, Flexibility: Polyimide Heaters are highly flexible and can be easily customized to fit various shapes and contours, allowing for versatile installation in complex geometries and space-constrained environments.

2, Thin Profile: These heaters have a low profile and are exceptionally thin, enabling their integration into applications where space is limited without adding significant bulk or weight.

3, Rapid Heating: Polyimide Heaters offer fast and efficient heating capabilities, reaching operating temperatures rapidly to provide prompt thermal response and energy-efficient performance.

4, Uniform Heat Distribution: The advanced thin-film construction of Polyimide Heaters ensures uniform heat distribution across the entire heating area, minimizing temperature variations and hot spots.

5, Chemical Resistance: Polyimide film, the primary component of these heaters, exhibits excellent resistance to a wide range of chemicals, oils, and solvents, enhancing the durability and longevity of the heating element.

6, Thermal Stability: These heaters demonstrate exceptional thermal stability, maintaining consistent performance across a broad temperature range and withstanding fluctuating environmental conditions.

7, Customizable Design: Polyimide Heaters can be tailored to specific voltage requirements, power outputs, shapes, and sizes, offering a high degree of customization to suit diverse application needs.

8, Integration Capabilities: They can be integrated with sensors, thermostats, and control systems to facilitate precise temperature control and monitoring, enhancing operational safety and efficiency.

9, Durability: With robust construction and resistance to mechanical stress, Polyimide Heaters are durable and reliable in demanding industrial environments.

Applications of PI Heaters :

PI Heaters, renowned for their versatility and efficiency, find wide-ranging applications across numerous industries. Their flexible and customizable nature makes them ideal for various heating needs.

1, Test and Research: PI Heaters are utilized in crystal ovens, IC testers, mechanically-heated structures, and flasks, providing precise and uniform heating essential for research and testing processes.

2, Medical Care and Beauty Industries: In the medical and beauty sectors, Polyimide Heaters are integral components in electric heating waistbands, knee pads, insoles, gloves, mouse pads, clothing, pet garments, baby bottle warmers, and more, ensuring consistent and reliable heat for therapeutic and comfort purposes.

3, Agriculture and Animal Husbandry: These heaters are employed in seedling breeding, poultry and livestock warming, fish breeding, incubators, and electric blankets for animal care, facilitating optimal environmental conditions for growth and nurturing.

4, Medical Instruments: PI Heaters play a crucial role in maintaining the temperature for medical instrument disinfection, blood storage, and for warming injections and drips, ensuring the efficacy and safety of medical procedures.

5, Instruments Temperature Control: PI Heaters are utilized in gyro-accelerating detectors, tail-wing operating devices, and aero-photographic apparatus, contributing to stable and controlled operating temperatures for precise instrument functionality.

6, Electric Appliances: In the realm of electric appliances, Polyimide Heaters are integrated into electric cookers, refrigerator defrosting systems, accumulators, electric blankets, greenhouse heating, wardrobe warmers, coffee pots, crystal-electric cookers, bathroom-mirror defoggers, and electronic-thermos devices, serving diverse heating requirements.

7, Transportation: PI Heaters are applied for defogging car mirrors and signals, as well as for water tank heating in various transportation vehicles, ensuring clear visibility and operational readiness.

8, Other Applications: Additional uses include electronic copiers, food fermentation, food warming boxes, circuit heating, water bed heating systems, and more, demonstrating the adaptability and broad utility of Polyimide Heaters across different domains.

Why Choose PANDA PCB for Polyimide Heaters ?

At PANDA PCB, We specialize in producing flexible Polyimide Heaters and PET Heaters that cater to a wide array of applications ranging from apparel, automotive seat warming, aerospace, food service, to health care and medical sectors. Our innovative heating technology sets us apart from traditional methods, offering superior performance and design versatility.

● Advanced Heating Technology: Unlike conventional wire or coil-based heaters that often result in uneven heating patterns, our Polyimide Heaters ensure consistent warmth across the entire surface. With self-regulating capabilities, these heaters maintain the desired temperature without the need for external controls, leading to enhanced safety and reliability.

● Design Flexibility: PANDA-PCB's Flexible Heaters empower you to think creatively and solve thermal management challenges with ease. Our heaters can be tailored to fit complex shapes and geometries, providing efficient heat distribution while maximizing space utilization. Engineers at PANDA PCB design around your equipment's contours, ensuring a seamless integration that doesn't compromise on performance.

● Optimized Performance: Our Polyimide Heaters are crafted using flexible, printed positive temperature coefficient materials that offer superior heat regulation and uniformity. By utilizing resistive alloys such as Inconel and Cupro-Nickel, we achieve precise control over resistance values based on supply voltage, resulting in efficient heat generation for diverse applications.

● Wide Range of Applications: Whether you require heating solutions for consumer goods, medical equipment, aerospace technologies, or automotive systems, PANDA-PCB's Polyimide Heaters deliver exceptional performance and reliability. Our single-layer flexible circuits are designed to meet the most demanding requirements, making them an ideal choice for various industries.

● Efficiency and Value: By choosing PANDA PCB for your heating needs, you benefit from cost-effective solutions that prioritize efficiency and value. Our heaters operate optimally in open-loop systems, reducing field issues and ensuring long-term performance without the need for constant adjustments.

PANDA PCB stands out as a trusted provider of Polyimide Heaters and PET Heaters, offering cutting-edge technology, design flexibility, and unmatched performance across diverse applications. Choose PANDA PCB for innovative heating solutions that meet your unique requirements with precision and reliability.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters