Ceramic-Thick Film Heaters

Ceramic-Thick Film Heaters, also called Thick Film-Ceramic Heaters, are produced by coating a ceramic substrate with a thick layer of resistive material, which is then sintered at high temperatures to create reliable circuits that offer precise heat control and durability, allowing these heaters to operate efficiently in a variety of industrial applications, providing uniform heat distribution and long service life due to the robustness of the ceramic substrate and the advanced thick-film technology.

Ceramic-Thick Film Heaters offer significant customization options, providing flexibility to meet specific heating requirements. Through thick-film technology, manufacturers can precisely control the characteristics of the resistive layer, tailoring the power density, heating speed, and temperature range of the heating elements. This adaptability makes them ideal for use in applications ranging from small-scale devices to large industrial systems. Whether used in medical equipment, automotive heating, or plastic molding processes, Ceramic-Thick Film Heaters can be engineered to fit unique specifications, ensuring optimal performance and energy efficiency for every use case.

Thick Film-Ceramic Heaters are widely used in industries where precise temperature control, durability, and efficiency are essential. These heaters are commonly employed in sectors such as automotive, medical devices, household appliances, and chemical processing. Their high-temperature tolerance and resistance to corrosion make them perfect for use in harsh environments. Additionally, their quick response times and energy-efficient operation have made them a preferred solution for applications like sterilization, plastic forming, and various heating systems. Their ability to be customized further enhances their utility across multiple industries, making them a vital component in many modern technological solutions.

Main Features of Ceramic-Thick Film Heaters :

● High-Temperature Stability: Ceramic Thick Film Heaters are designed to operate at high temperatures without significant degradation, which makes them suitable for demanding environments.

● Uniform Heat Distribution: The thick film technology ensures that heat is distributed evenly across the surface, leading to efficient and consistent heating.

● Long Lifespan: Due to the robustness of the ceramic material and the thick film heating element, these heaters have a longer operational life compared to traditional heating elements.

● Corrosion Resistance: Ceramic is naturally resistant to many corrosive substances, allowing the heaters to be used in environments where other materials might deteriorate.

● Fast Response Time: The quick heat-up and cool-down characteristics of Ceramic Thick Film Heaters make them ideal for applications that require rapid changes in temperature.

● Customizable Design: The thick film technology allows for a high degree of customization in terms of size, shape, and power output to fit specific application requirements.

● Energy Efficiency: Ceramic Thick Film Heaters convert electrical energy into heat very efficiently, which can lead to energy savings in the long run.

● Low Thermal Mass: The low thermal mass means that the heaters can quickly reach the desired operating temperature, which is beneficial for applications with frequent on-off cycles.

● Good Thermal Conductivity: Ceramic materials have good thermal conductivity, which helps in transferring heat effectively to the target area.

● Reliability and Durability: The construction and materials used in Ceramic Thick Film Heaters contribute to their reliability and durability, making them a preferred choice for critical applications.

● Flexibility in Application: They can be used in a wide range of applications, from industrial processes to medical equipment, due to their versatility.

● Low EMI (Electromagnetic Interference): Ceramic heaters typically produce less electromagnetic interference, which is advantageous in sensitive electronic environments.

● Environmentally Friendly: The materials used are often lead-free and RoHS compliant, making them more environmentally friendly.

● Safety Features: Many ceramic thick film heaters are designed with safety in mind, including features that prevent overheating and other potential hazards.

Applications of Thick Film-Ceramic Heaters :

1, Food Industry: In the food industry, Thick Film Ceramic Heaters are commonly used for caramelizing breads, warming and heating foods, and other cooking processes that require precise and uniform heat distribution. Their high thermal conductivity and efficient energy transfer make them ideal for commercial kitchens, bakeries, and food processing facilities.

2, Coating and Curing Applications: Thick Film Ceramic Heaters are extensively employed in coating and curing processes where controlled heating is crucial for achieving desired results. These heaters provide consistent and even heat distribution, ensuring proper curing of coatings on various substrates in industries such as automotive, aerospace, and manufacturing.

3, Plastic Welding and Softening: The ability of ceramic thick film heaters to reach high temperatures quickly makes them suitable for plastic welding and softening applications. They enable efficient bonding of plastic components in industries like automotive, electronics, and packaging, where precision and reliability are paramount.

4, Semiconductor Industry: In the semiconductor industry, ceramic thick film heaters are utilized for critical processing applications requiring ultra-pure conditions. Their low thermal expansion, high temperature stability, and chemical inertness make them ideal for semiconductor manufacturing processes, including wafer processing and cleanroom environments.

5, Medical Equipment: Ceramic thick film heaters play a vital role in medical equipment where precise and consistent heating is essential. From heating elements in diagnostic devices to therapeutic applications requiring controlled temperatures, these heaters provide reliable performance in medical settings.

6, Industrial Heating Systems: Ceramic thick film heaters are integrated into industrial heating systems for applications such as mold heating, plastic extrusion, and temperature control in various manufacturing processes. Their durability, high power density, and rapid response make them a preferred choice for industrial heating requirements.

Application in Automotive of Thick Film-Ceramic Heaters :

● Temperature Control Systems: Thick Film Ceramic Heaters are used for temperature management in various automotive components, such as sensors and batteries. They can provide precise and efficient heating for temperature-sensitive components, ensuring optimal performance and longevity.

● Heating Components: In some high-end vehicles, Thick Film Ceramic Heaters are used for seat heaters, window and mirror defrosters, and even for heating passenger compartments. Their fast response times and uniform heat distribution make them ideal for these applications.

● Engine and Exhaust Systems: Thick Film Ceramic Heaters can be employed to heat engine components or the exhaust system for improved cold-start performance and reduced emissions, particularly in cold climates.

● Electrical Vehicle (EV) Components: With the rise of EVs, Thick Film Ceramic Heaters are used in battery management systems to maintain optimal battery temperature, which is crucial for performance and safety.

● Fuel Systems: Thick Film Ceramic Heaters can be used in fuel systems to ensure proper fuel flow and prevent issues related to cold temperatures, such as waxing in diesel fuel systems.

● Catalytic Converters: They can be used to quickly bring catalytic converters up to operating temperature, reducing the time it takes for the vehicle to meet emission standards.

● Sensors and Actuators: Thick Film Ceramic Heaters are also used to heat sensors and actuators that require a stable and controlled temperature to function correctly.

● Exterior Applications: For exterior applications like lighting systems, Thick Film Ceramic Heaters can provide the necessary heat to prevent fogging or icing, ensuring visibility and safety.

Types of Ceramic-Thick Film Heaters :

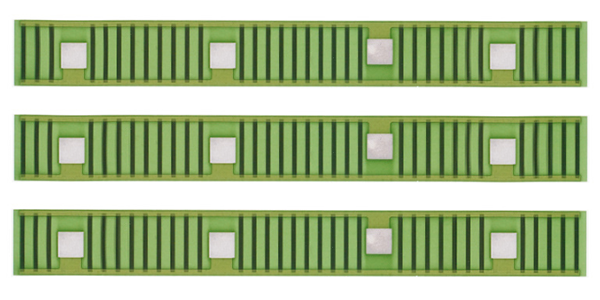

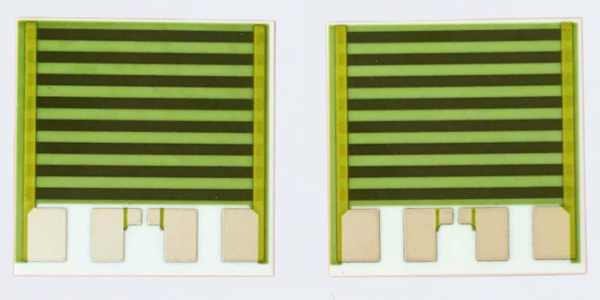

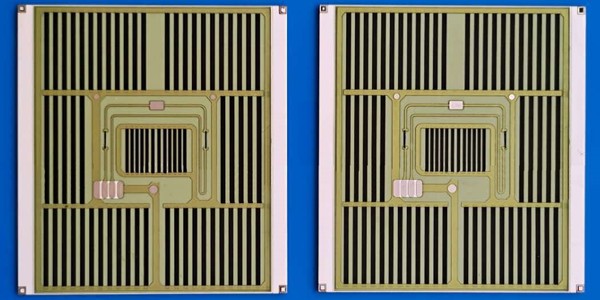

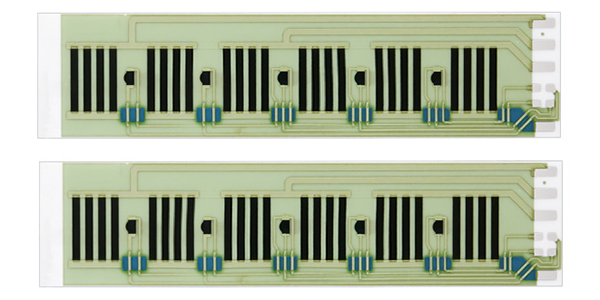

1, Flat Plate Heaters: Flat plate ceramic thick film heaters consist of a flat surface with a heating element printed on a ceramic substrate. These heaters provide uniform heat distribution across the entire surface area, making them ideal for applications such as heating platens, laminating processes, and heat sealing.

2, Cartridge Heaters: Cartridge heaters incorporate a cylindrical design with a ceramic core and thick film heating element. They are commonly used in applications where localized heating is required, such as injection molding, packaging machinery, and hot stamping equipment.

3, Tubular Heaters: Tubular ceramic thick film heaters feature a tubular shape with a heating element coated on the ceramic surface. These heaters are versatile and used in applications such as fluid heating, air heating, and industrial ovens where efficient heat transfer and high power density are essential.

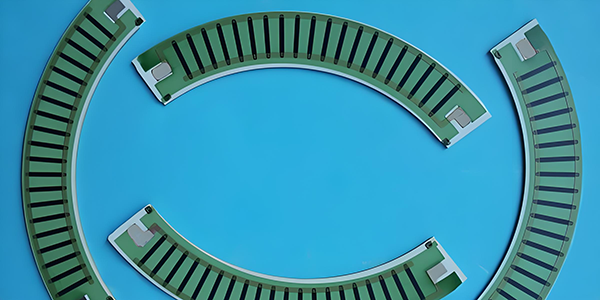

4, Customized Shapes and Sizes: Manufacturers can create customized ceramic thick film heaters in various shapes and sizes to meet specific application requirements. Whether it's a unique geometrical design or a heater tailored for a specialized task, custom ceramic thick film heaters offer flexibility and precision in heating solutions.

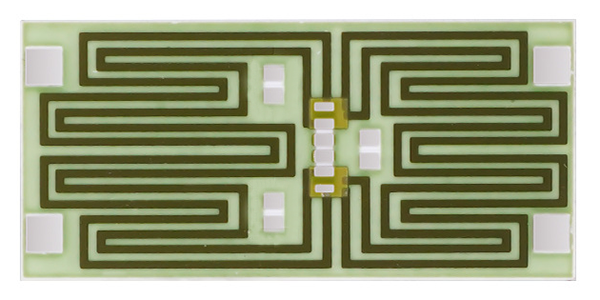

5, Integrated Heating Systems: Some ceramic thick film heaters are integrated into complete heating systems that combine multiple heating elements, temperature sensors, and control mechanisms. These integrated systems are utilized in complex industrial processes requiring precise temperature control and automation.

6, High-temperature Ceramic Heaters: Specialized ceramic thick film heaters designed to operate at extremely high temperatures, exceeding 700°C (1300°F), cater to applications demanding elevated heat levels. These high-temperature heaters are used in industries such as aerospace, metallurgy, and advanced materials processing.

7, Multi-zone Heaters: Multi-zone ceramic thick film heaters feature multiple heating elements controlled independently to create distinct heating zones within a single unit. These heaters are utilized in applications where different temperature gradients or heating profiles are needed, such as semiconductor processing and analytical instrumentation.

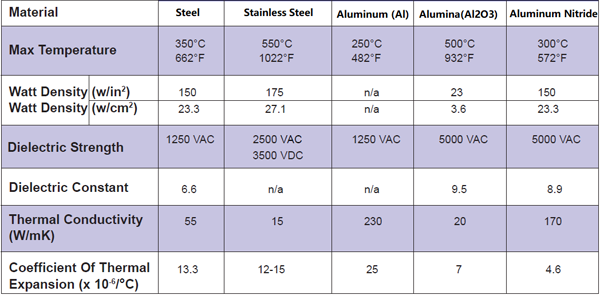

Substrates Comparison of Ceramic-Thick Film Heaters :

Why Deed to Custom Ceramic-Thick Film Heaters ?

● Size and Shape: The physical dimensions of the heater can be altered to fit the space constraints and shape requirements of the application. This could mean creating a heater that is long and narrow, circular, or even a complex shape to match the object being heated.

● Power Output: The power rating of the heater can be adjusted to provide the exact amount of heat needed for a particular process. This prevents over- or under-heating and ensures energy efficiency.

● Thermal Profile: The heat distribution across the surface of the heater can be engineered to match the thermal profile of the application. For instance, a specific area might require more heat, and the design can be adjusted to concentrate the heating element in that region.

● Surface Material: The surface of the ceramic can be coated with different materials to improve its emissivity, corrosion resistance, or to provide a specific type of thermal coupling with the object being heated.

● Connection Options: The terminals and connectors can be customized to fit the electrical interface of the system into which the heater will be integrated.

● Mounting Options: Heaters can be designed with various mounting solutions, such as adhesive backing, clips, or brackets, to ensure secure and efficient installation.

● Control Integration: For applications requiring precise temperature control, the heater can be integrated with control circuits and sensors to provide feedback and maintain a set temperature.

● Resistance to Specific Environments: If the application involves exposure to certain chemicals, moisture, or other environmental factors, the ceramic material and the thick film can be selected or treated to resist these conditions.

● Aesthetics: In some cases, the appearance of the heater might be important, and the design can be customized to match the aesthetic requirements, such as color or finish.

● Regulatory Compliance: Custom designs can ensure that the heaters meet specific regulatory standards or certifications required for the industry or region where they will be used.

● Fail-Safe Mechanisms: Heaters can be designed with built-in safety features, such as thermal fuses or breakaway tabs, that activate in the event of an abnormal condition to prevent damage or failure.

● Energy Efficiency Standards: Custom designs can optimize the heater's performance to meet or exceed energy efficiency standards, which can be important for both environmental and economic reasons.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters