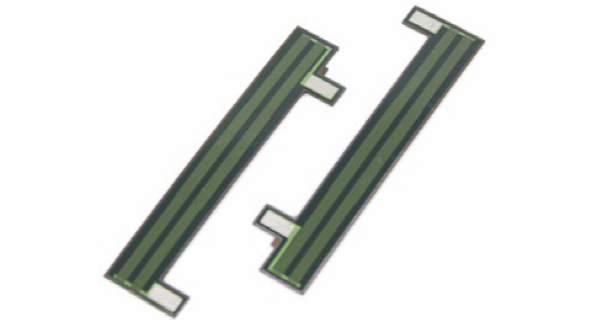

Optical Fibre Fusion Splicer-Heaters

Optical Fibre Fusion Splicer-Heaters are advanced heating elements designed to support prolonged on-site heating processes in optical fibre fusion splicers, utilizing thick film heating technology with stainless steel or ceramic substrates and a printed thick film paste (conductive, resistive) as the core heating conductor, ensuring efficient, energy-saving, and reliable heating capabilities for seamless fusion splicing operations.

Optical Fibre Fusion Splicer-Heaters are engineered for precision and durability, offering high thermal performance to meet the demanding requirements of fibre splicing. Their advanced thick film technology allows for uniform heat distribution, ensuring the fibre ends are fused consistently, minimizing the risk of splice loss or damage. This precision enhances the overall quality of the optical fibre network, making it more reliable for data transmission.

Optical Fibre Fusion Splicer-Heaters are designed for long-term use in various environments, offering energy efficiency and reduced power consumption. Their robust construction withstands frequent thermal cycling and harsh conditions, making them ideal for both field and factory applications. The combination of durability, efficiency, and reliable heating performance ensures these heaters maintain high-quality fusion splices, reducing maintenance costs and increasing the overall lifespan of fusion splicing equipment.

Features of Optical Fibre Fusion Splicer-Heaters :

● Advanced Thick Film Heating Technology: Optical Fibre Fusion Splicer-Heaters utilize thick film technology, incorporating conductive and resistive materials on stainless steel or ceramic substrates. This allows for efficient and uniform heat distribution, which is essential for achieving high-quality fusion splices.

● Energy Efficiency: These heaters are designed with energy-saving features, ensuring low power consumption without compromising on heating performance. This reduces operational costs and helps extend the battery life of portable splicing equipment.

● High Durability: Built to withstand the rigors of frequent use, Optical Fibre Fusion Splicer-Heaters are made from robust materials that resist wear and tear. They can endure repeated thermal cycles and harsh working conditions, ensuring long-lasting reliability.

● Precise Temperature Control: These heaters offer precise temperature regulation, ensuring the fibre is heated evenly during the splicing process. This accuracy helps reduce the risk of splice defects and improves the overall quality of the fusion splice.

● Quick Heating Time: Optical Fibre Fusion Splicer-Heaters are designed for rapid heating, allowing technicians to perform splicing operations efficiently. This short heating time helps increase overall productivity during fibre splicing tasks.

● Compatibility with Various Fibre Types: These heaters are versatile and can be used with a variety of fibre types, including single-mode and multi-mode fibres. This feature makes them suitable for a wide range of applications in telecommunications, data networks, and other fibre optic systems.

● Compact and Portable Design: Optical Fibre Fusion Splicer-Heaters are designed to be compact and portable, making them ideal for on-site use. Their lightweight construction ensures ease of transport, allowing technicians to carry them to different job locations effortlessly.

● Improved Safety Features: Many models of these heaters are equipped with built-in safety features, such as overheat protection and automatic shut-off mechanisms, to prevent accidents and ensure safe operation in both field and factory environments.

Advantages of Optical Fibre Fusion Splicer-Heaters :

● Efficient and Uniform Heating: The thick film paste on the substrate ensures efficient heat conduction and uniform heating distribution, vital for achieving high-quality fusion splicing results.

● Stability and Reliability: Thick film heaters offer stable and reliable performance, capable of sustaining prolonged on-site heating processes without compromising quality.

● Rapid Heat Transfer: The technology enables fast heat conduction, contributing to swift heat-up times and overall operational efficiency.

● Energy Conservation: By minimizing heat loss and optimizing heat transfer, thick film heaters promote energy conservation and cost-effective operation, aligning with modern energy efficiency standards.

Optical Fibre Fusion Splicer-Heaters represent an indispensable solution for sustained and efficient heating requirements in optical fibre fusion splicing. With their robust features and energy-saving capabilities, these heaters are essential for achieving reliable and high-performance fusion splicing operations.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters