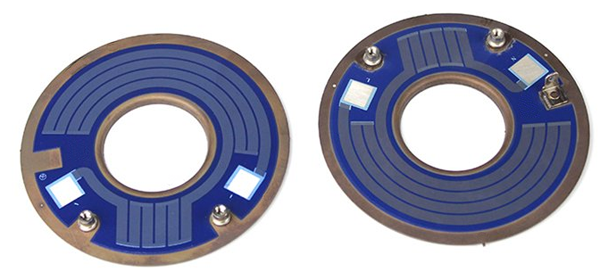

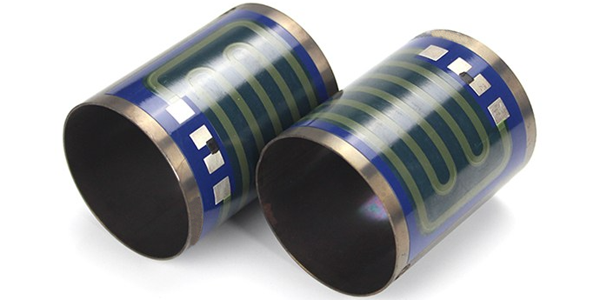

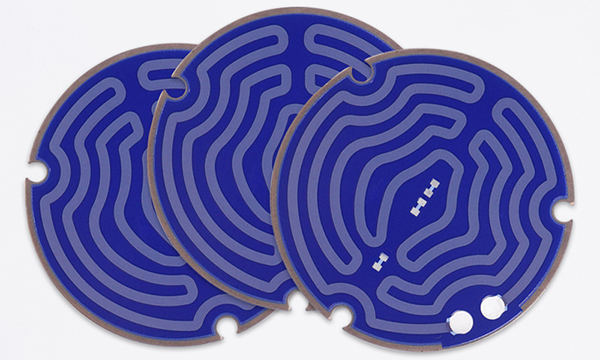

Stainless Steel-Thick Film Heaters

Stainless Steel-Thick Film Heaters, also known as Stainless Steel-Heaters, are high-efficiency, reliable, corrosion-resistant, and precise heating elements made from stainless steel substrates in either flat or tubular forms, combined with thick-film heating technology, which involves precisely printing conductive, insulating, and resistive materials as thin films onto the stainless steel surface, followed by a high-temperature sintering process that forms a uniform heating layer, ensuring excellent heat distribution, high-temperature resistance, and long-term stability.

Stainless Steel-Thick Film Heaters are widely used in various industries, such as automotive, medical devices, aerospace, industrial equipment, and semiconductor processing, due to their exceptional durability, corrosion resistance, fast response time, uniform heating performance, and efficient heat transfer characteristics. They can operate stably in high-temperature, humid, or corrosive environments and offer high customization capabilities, allowing for the design of heating elements in different sizes, shapes, and power outputs to meet diverse requirements, providing excellent heating solutions in complex applications.

Stainless Steel-Thick Film Heaters not only exhibit outstanding physical and chemical properties but also enable efficient energy utilization through precise thermal control. Their corrosion resistance makes them ideal for use in chemical processing, liquid heating, and other harsh environments, while their excellent thermal response and fast start/stop characteristics make them the preferred choice in applications requiring high heating precision. For example, in the medical device field, thick-film heaters are widely used in critical processes such as blood heating, drug temperature control, and surgical instrument heating, improving work efficiency and accuracy while ensuring safety.

Stainless Steel-Heaters also have an excellent long lifespan, maintaining high performance even during prolonged continuous operation or under extreme conditions, reducing the costs and maintenance work associated with frequent equipment replacements. Their flexibility and customizability allow engineers to optimize parameters such as shape, power, and temperature control accuracy according to specific technical requirements, adapting to different industrial needs, such as heating requirements in high-temperature, high-pressure environments in aerospace.

Materials of Stainless Steel-Thick Film Heaters :

Stainless Steel-Thick Film Heaters consist of several key materials that work together to provide efficient and reliable heating performance. These materials include:

1, Substrates: The substrate of a Stainless Steel-Thick Film Heater is typically made of stainless steel, such as SUS304 or SUS430, which provides a sturdy base for the heating element. Stainless steel offers excellent thermal conductivity, corrosion resistance, and mechanical strength, making it ideal for high-temperature applications.

● SUS304 Stainless Steel

Dimension : ø 10 - 150mm,Thickness 0.5 - 2.5mm

Details of contents : Ni 8.0~10.5, Cr 18.0~22.0, Mn 2.0 MAX, Fe Bal。

Proper environment : Air heating,Kettle heating plate。

Limit service temperature : 400°C or less。

● SUS430 Stainless Steel

Dimension : ø 10 - 150mm,Thickness 0.5 - 2.5mm

Details of contents : Ni ≦ 0.60, Cr 16.0~18.0, Mn 1.0 MAX, Fe Bal.

Proper environment : Air heating,Kettle heating plate.

Limit service temperature : 400°C or less.

2, Conductive Paste: The conductor paste is used to create the resistive heating element on the stainless steel substrate. This paste is formulated with materials such as silver, copper, or nickel to achieve the desired electrical conductivity and heat generation properties.

3, Resistive Paste: The resistor paste is applied over the conductor paste to form the resistive layer of the heater. This paste is designed to have a specific resistivity to control the amount of heat generated by the heater when an electrical current passes through it.

4, Dielectric Paste: The dielectric layer paste is used to insulate the resistive layer and prevent electrical shorts. This layer is crucial for maintaining the integrity and safety of the heater, especially in high-voltage applications.

5, Insulation Paste: The insulation layer paste is applied over the entire heating element to provide additional protection and thermal insulation. This layer helps to improve the efficiency of the heater by minimizing heat loss and ensuring uniform heat distribution.

By carefully selecting and applying these materials, Stainless Steel-Thick Film Heaters can deliver precise and consistent heating performance across a wide range of industrial and commercial applications.

Features of Stainless Steel-Thick Film Heaters :

1, Efficient Heating: Stainless Steel-Thick Film Heaters are designed to provide efficient and rapid heating due to their high thermal conductivity and uniform heat distribution across the heating element.

2, Versatility: These heaters can be customized to suit a wide range of applications and requirements, making them versatile for various industrial and commercial heating needs.

3, Compact Design: Stainless Steel-Thick Film Heaters have a compact and space-saving design, allowing for easy integration into different systems and equipment.

4, Durability: With a stainless steel substrate and protective layers, these heaters offer excellent durability and resistance to corrosion, ensuring long-term reliability even in harsh operating conditions.

5, Fast Response Time: The thin layers of materials used in these heaters enable quick response times for heating and temperature control, making them ideal for applications that require rapid heating cycles.

6, Precise Temperature Control: Stainless Steel-Thick Film Heaters can achieve precise temperature control and maintain consistent heating profiles, contributing to accurate and reliable performance.

7, Customizability: These heaters can be tailored to specific wattages, voltages, shapes, and sizes to meet the unique heating requirements of different applications.

Advantages of Stainless Steel-Heaters :

1, Rapid Heating: Stainless Steel-Heaters provide quick and efficient heating due to their high thermal conductivity and responsive design.

2, Durability: With a stainless steel substrate and protective layers, they offer excellent durability and corrosion resistance for long-term reliability.

3, Versatility: Stainless Steel-Heaters can be customized to suit various applications and are adaptable to different shapes and sizes.

4, Precise Temperature Control: Stainless Steel-Heaters enable accurate and consistent temperature control, ensuring reliable performance.

5, Compact Design: Stainless Steel-Heaters have a space-saving design, allowing for easy integration into different systems and equipment.

6, Customizability: Stainless Steel-Heaters can be tailored to specific wattages, voltages, and heating profiles to meet diverse application requirements.

Applications of Stainless Steel-Heaters :

● Industrial Processes: Used in processes that require precise temperature control, such as chemical reactions or material curing.

● Medical Equipment: For heating components in medical devices where sterility and reliability are crucial.

● Automotive: In heating systems for vehicle interiors or for defrosting windshields.

● Aerospace: For in-flight heating systems or for maintaining equipment at optimal temperatures.

● Domestic Appliances: In appliances like toasters, ovens, and water heaters for efficient and even heating.

● Process Control Systems: For maintaining consistent temperatures in manufacturing and processing equipment.

● Laboratory Equipment: In scientific and laboratory settings for controlled heating of samples or reactions.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters