E-Cigarettes Heaters

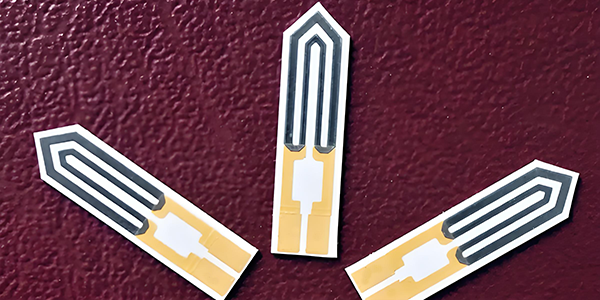

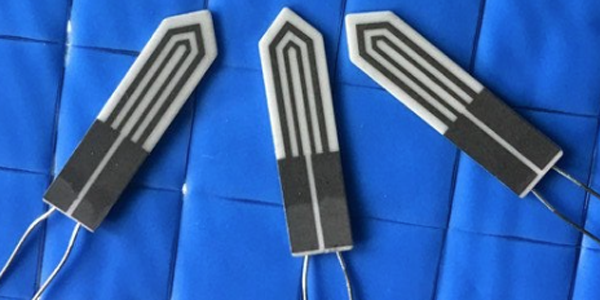

E-Cigarettes Heaters, also called Electronic Cigarettes Heaters, are common heating methods in Heat-Not-Burn (HNB) electronic cigarettes and utilize resistance heating technology, where the basic principle involves generating Joule heat through current passing through resistors to heat tobacco sticks or e-liquid cartridges, with the heaters, as some of the core components in electronic cigarettes, functioning to heat the tobacco or e-liquid in the cartridges to specific temperatures to produce inhalable vapor.

E-Cigarettes Heaters are specialized heating elements that utilize metal resistance paste printed on the surface of ceramic substrates, with the resistance material serving as the core component for heating. This design allows for rapid heating, making the devices highly efficient. E-Cigarettes Heating Elements are versatile and applicable to a wide variety of non-burning smoke devices, and they also support customized services, offering flexibility to cater to different product designs and consumer preferences.

Electronic Cigarettes Heaters, based on Thick Film Ceramic Heater Technology, have their origins in hybrid circuits that were developed for military and automotive applications, thanks to their high reliability and performance under harsh conditions. The term "thick film" refers to a manufacturing process where the circuit or heating element is applied to the substrate through screen printing. This process involves using inks that contain a blend of ceramics and metals to fabricate resistors and conductors. Common materials used in the manufacturing of these heating elements include metals such as silver, gold, silver palladium, gold platinum, copper, and ruthenium, which provide the necessary conductivity and durability for optimal performance in electronic cigarettes.

Our engineering team specializes in developing innovative thick film heating solutions across a broad spectrum of applications. These solutions cater to diverse needs, from consumer products and medical devices requiring rapid and precise heating to commercial food equipment necessitating uniformly heated surfaces.

Substrates of E-Cigarettes Heaters :

The substrate in thick film heating technology forms the foundation material for heating elements, commonly using materials like stainless steel, ceramics, and other high-temperature resistant materials.

● Stainless Steel: Stainless steel, known for its corrosion resistance and mechanical strength, can withstand the high temperatures and thermal cycles during the heating process.

● Ceramics (Alumina, Zirconia, etc.): Ceramic materials offer excellent high-temperature resistance and thermal stability, often used in manufacturing heating elements. Alumina ceramics are widely applied due to their high insulation, abrasion resistance, and good thermal conductivity, while zirconia ceramics are favored for their higher mechanical strength and thermal stability.

Heating Paste Materials of E-Cigarettes Heaters :

Heating paste is a crucial material for manufacturing resistance heating elements, comprising conductors, carbon ink, and insulators.

● Conductors: Typically metal powders like silver, copper, providing necessary electrical conductivity in the paste, forming the core part of the heating element.

● Carbon Ink: Used as a conductive filler, carbon ink enhances the electrical conductivity of the heating paste and contributes to uniform heating.

● Insulators: Insulators such as glass powder, alumina, are utilized to isolate conductive particles, prevent short circuits, and act as a framework during curing and sintering processes.

Production Processes of Electronic Cigarettes Heaters :

● Printing: Precisely coating the heating paste onto the substrate through screen printing or other techniques to create the desired resistance pattern.

● Curing: The printed substrate undergoes curing to remove organic solvents from the paste, resulting in a mechanically robust cured layer.

● Sintering: The cured substrate undergoes high-temperature sintering to form strong metal bonds between conductive particles, enhancing resistance stability and durability.

Advantages of E-Cigarettes Heaters :

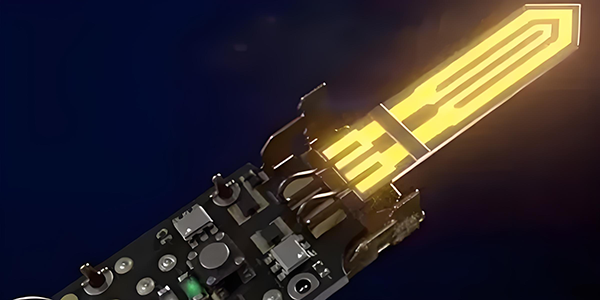

● Exceptional Mechanical Strength and Uniform Temperature:

Utilizing specialized ceramic substrates, E-Cigarettes Heaters deliver optimal mechanical strength and ensure uniform temperature distribution, contributing to reliable and consistent heating performance.

● High Accuracy and Stable Load Characteristics:

The metal resistance components exhibit high accuracy and stable load characteristics, enabling precise control over the heating process for an enhanced vaping experience.

● Strong Adhesion and Durability:

The resistance film demonstrates strong adhesion with ceramics, safeguarding against detachment even after repeated use, ensuring long-term reliability and durability.

● Resilient High-Temperature Glaze Coating:

The heater is coated with a high-temperature glaze, making it suitable for operation in harsh environments, ensuring resilience and longevity under demanding conditions.

● Enhanced Soldering Pad Surface:

Soldering pad surfaces are plated with gold, improving solderability and weldability, facilitating efficient assembly and maintenance processes.

● Customizable Solutions:

E-Cigarettes Heaters can be customized and developed according to specific customer requirements, ensuring compatibility with a wide range of electronic cigarette designs and configurations.

● Compact, Lightweight, and Energy-Efficient Design:

Featuring high watt density and excellent thermal efficiency, Ceramic Heaters are compact, lightweight, and energy-efficient, allowing for multiple heating elements to be layered into a single unit, optimizing space utilization and power consumption.

● Superior Thermal Properties:

Ceramic Heaters reach high temperatures rapidly and can be designed with custom heat distribution patterns, while their strong insulation properties enable direct contact with various materials, including water, kerosene, and metals.

● High Reliability and Safety:

E-Cigarettes Heaters boast superior dielectric strength, electrical insulation, and chemical resistance, ensuring outstanding reliability and safety throughout their operational lifespan.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters