Flexible Heaters

Flexible Heaters, or called Flex Heaters, are versatile electric heating devices designed to function efficiently even when bent or flexed around curves and corners, constructed from thin, flexible materials that incorporate heating elements, making them adaptable to a wide range of applications in spaces where traditional rigid heating elements may not fit, and often backed with adhesive, they allow for easy installation on various surfaces, making them perfect for industries like automotive, medical devices, and electronics, where precise, flexible heating solutions are required.

Flexible Heaters offer superior performance due to their use of high-quality materials such as organic polyimide, silicone, and polyester films. These materials provide excellent tensile strength, tear resistance, and dimensional stability, making Flexible Heaters durable and reliable in diverse environments. The flexibility of these heaters ensures they maintain their efficiency even in complex, irregular shapes, making them ideal for customized heating applications in tight or constrained spaces.

Flexible Heaters are designed to meet a wide range of temperature needs with their advanced construction. By using materials like polyimide (PI), silicone, and polyester (PET), they offer high-performance characteristics, including excellent heat distribution and energy efficiency. This makes them an essential solution for applications that require consistent, controlled heat, such as in medical devices, electronic components, and automotive systems, where precise temperature regulation is critical.

Types of Flexible Heaters :

Based on the substrate material and manufacturing process, Flexible Heaters can be categorized into two main types:

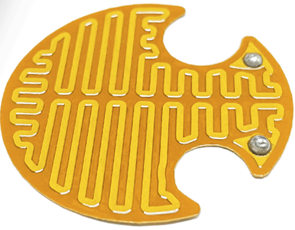

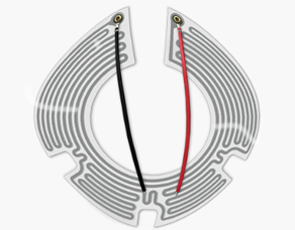

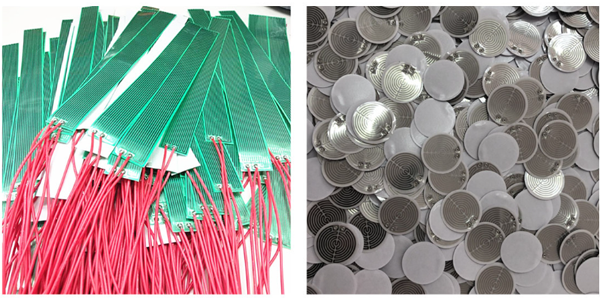

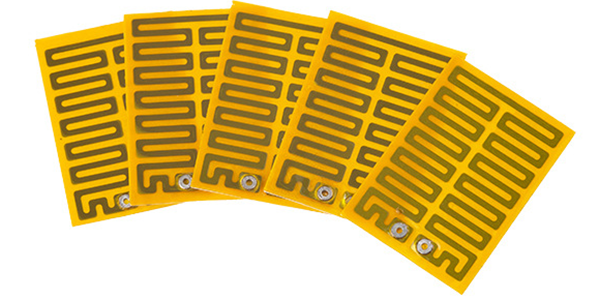

● Polyimide Heater: Constructed using polyimide film, these heaters offer exceptional thermal stability and flexibility, suitable for high-temperature applications.

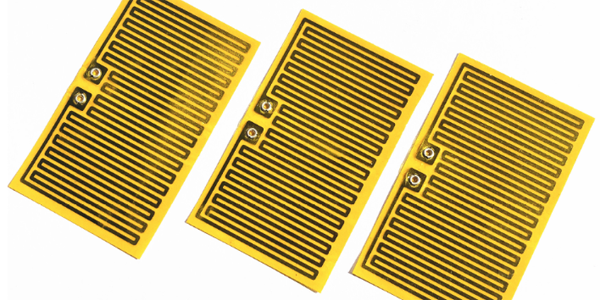

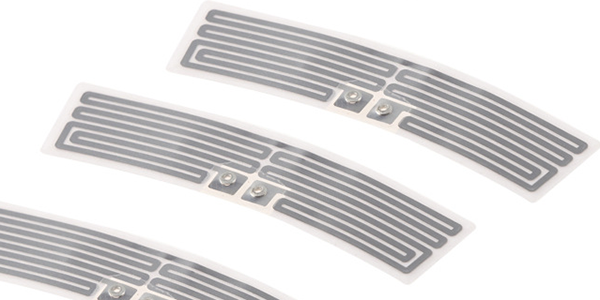

● Polyester Heater: Made from polyester film, these heaters provide cost-effective heating solutions with durability and flexibility, ideal for applications not requiring high-temperature performance.

|

|

Features of Flexible Heaters :

● Flexibility: The primary feature of flexible heaters is their ability to bend and conform to different shapes and surfaces without losing their heating capabilities. This makes them ideal for heating irregularly shaped objects or for use in tight spaces.

● Uniform Heat Distribution: Flexible heaters are engineered to distribute heat evenly across their surface, ensuring that the heat is applied consistently, which is crucial for applications requiring precise temperature control.

● Customizable Sizes and Shapes: Flexible Heaters can be cut and shaped to fit specific dimensions, allowing for a tailored fit to the object or area that needs to be heated.

● Energy Efficiency: Many flexible heaters are designed to be energy-efficient, converting a high percentage of electrical energy into heat with minimal energy loss.

● Safety Features: Modern flexible heaters often incorporate safety features such as automatic shut-off in the event of overheating, and they may be made with materials that are resistant to high temperatures to reduce the risk of fire.

● Durability: High-quality flexible heaters are made with durable materials that can withstand regular use and resist wear and tear, making them long-lasting even in demanding environments.

● Easy Installation: Flexible Heaters are typically easy to install, often requiring only an adhesive backing or clips to secure them in place.

● Low Maintenance: Once installed, flexible heaters require minimal maintenance and have a low risk of mechanical failure.

● Silence: Unlike some mechanical heating systems, flexible heaters operate silently, making them suitable for environments where noise is a concern.

● Versatility: Flexible Heaters can be used in a wide range of applications, from household items like under-desk heaters to industrial processes requiring precise temperature control.

● Resistance to Corrosion and Moisture: Some flexible heaters are made with materials that make them resistant to corrosion and moisture, allowing them to be used in humid or wet environments.

● Quick Response Time: Flexible heaters can quickly reach the desired temperature, which is beneficial for applications that require rapid heating.

Polyimide Heaters VS Polyester Heaters :

● Material and Temperature Resistance:

Polyimide heaters are crafted from a high-temperature polymer that can endure temperatures up to 500°F (260°C), making them suitable for high-temperature industrial applications. In contrast, polyester heaters, made from a more common polyester film, are designed for lower temperature applications, typically up to 250°F (120°C), and are more cost-effective for such uses.

● Durability and Lifespan:

The robustness of polyimide material results in heaters that are more durable and have a longer lifespan, even in continuous high-temperature operations. Polyester heaters, while versatile, tend to have a shorter lifespan due to the limitations of the polyester material when exposed to high temperatures for extended periods.

● Flexibility and Conformability:

Both polyimide and polyester heaters can be manufactured to be flexible, allowing them to be conformed to various shapes and surfaces. This flexibility is advantageous for applications where the heater needs to fit specific contours.

● Electrical Properties:

Polyimide heaters generally offer better electrical insulation properties, making them a safer choice for environments where electrical sensitivity is a concern.

● Heat Distribution:

Polyester heaters are recognized for their even heat distribution, which is ideal for applications requiring uniform heating across a surface.

● Cost:

The cost of polyimide heaters is typically higher due to the more expensive material and the intricate manufacturing process required to produce them. Polyester heaters, on the other hand, are more cost-effective, making them a popular choice for applications where high-temperature resistance is not a primary concern.

Applications of Flexible Heaters :

● Medical Equipment: Flexible Heaters are used to maintain a comfortable temperature in medical devices and equipment, such as warming beds and incubators for newborns.

● Industrial Processes: Flexible Heaters are employed in industrial settings to maintain the temperature of machinery, prevent pipe freezing, and ensure the proper flow of viscous liquids.

● Automotive: Flexible Heaters are used to de-ice windshields and to keep car interiors warm during cold weather.

● Aerospace: In aerospace applications, flexible heaters are critical for maintaining the temperature of sensitive electronic components and for de-icing aircraft surfaces.

● Domestic Use: Flexible Heaters are popular for personal use in items like heated blankets, insoles for shoes, and even as a heating source for outdoor patios and terraces.

● Packaging: Flexible Heaters can be integrated into packaging to keep food and other temperature-sensitive goods at a safe temperature during transit.

● Construction: Flexible Heaters are used to prevent pipes from freezing in cold climates and to heat construction materials to ensure they set properly.

● Outdoor Applications: For outdoor events or in recreational vehicles (RVs), flexible heaters can provide localized warmth in tents, gazebos, or other temporary structures.

● Commercial Settings: In commercial kitchens, they can be used to keep food warm, and in retail settings, they can provide supplemental heat.

● Electronics: Flexible Heaters are used to prevent condensation and maintain a stable temperature in sensitive electronic devices.

● Military: Flexible Heaters serve as a source of warmth in military field gear, such as clothing and shelters.

● Aquariums and Terrariums: To maintain a consistent temperature in aquatic and terrarium environments for the well-being of the inhabitants.

● Manufacturing: In the manufacturing of certain products, flexible heaters can facilitate processes like curing, drying, or maintaining a stable temperature for chemical reactions.

● Footwear and Clothing: Built into the design of heated socks, gloves, and other garments to provide warmth in cold conditions.

Design Considerations for Flex Heaters :

1, Temperature Range: Ensure that the Flex Heater selected can operate within the required temperature range for the specific application. Consider factors such as ambient temperature variations and the maximum temperature the heater needs to reach.

2, Power Density: Determine the appropriate power density based on the heating requirements and the size of the area to be heated. Balancing power density with temperature uniformity is crucial to prevent hotspots and ensure even heating.

3, Voltage and Wattage: Select a Flex Heater that matches the voltage and wattage specifications of the power source available in the application. Proper matching prevents overheating or underperformance of the heater.

4, Size and Shape: Customize the size and shape of the Flex Heater to fit the contours of the target surface accurately. Consider the dimensions and geometry of the heating area to maximize efficiency and coverage.

5, Mounting Method: Choose a suitable mounting method that securely attaches the flexible heater to the surface to be heated. Options include adhesives, clamps, fasteners, or insulating materials, depending on the application requirements.

6, Flexibility and Durability: Ensure that the Flex Heater material offers the required flexibility to conform to curved or irregular surfaces without compromising performance. Verify the durability of the heater against mechanical stress, bending, and repeated use.

7, Moisture and Chemical Resistance: If the application involves exposure to moisture or chemicals, select a Flex Heater with appropriate protective coatings or materials to ensure reliability and longevity in harsh environments.

8, Thermal Insulation: Incorporate thermal insulation in the design to enhance efficiency and minimize heat loss to the surroundings. Proper insulation can improve the performance of the flexible heater and reduce energy consumption.

9, Temperature Control and Safety Features: Integrate temperature control mechanisms such as thermostats, thermal fuses, or temperature sensors to maintain safe operating temperatures and prevent overheating. Implement safety features to detect malfunctions and ensure user protection.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters