Stainless Steel-Thick Film Heating Elements

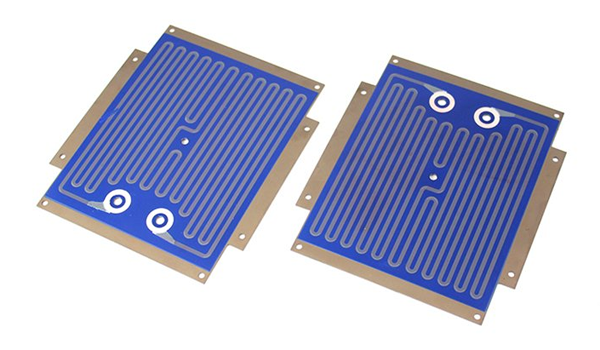

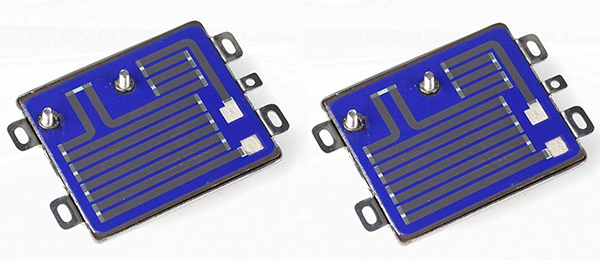

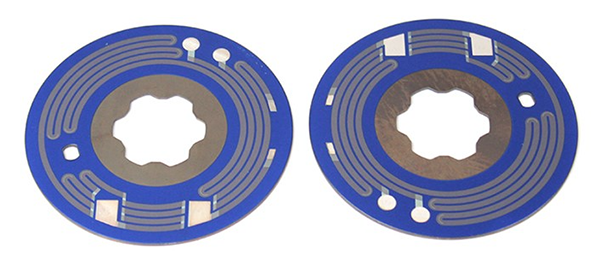

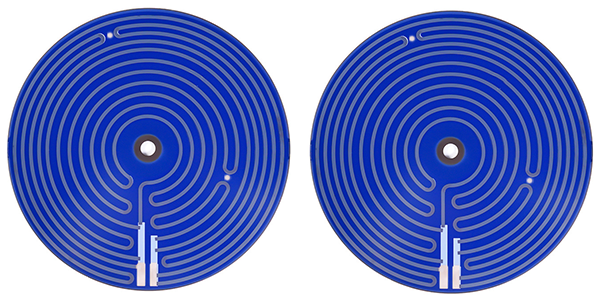

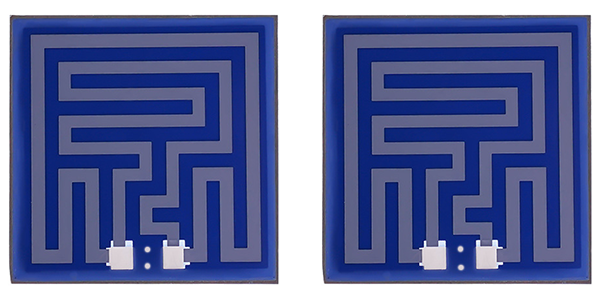

Stainless Steel-Thick Film Heating Elements, also referred to as Stainless Steel-Heating Elements, are highly efficient, safe, and customizable resistive heating devices manufactured using thick-film technology, where dielectric, conductive, resistive, and insulating materials are printed in layers onto a stainless steel substrate and then subjected to a high-temperature firing process, resulting in heating elements that offer high design flexibility, precision, and durability.

Stainless Steel-Thick Film Heating Elements are characterized by exceptional reliability and performance. Their structure and materials can be customized to meet specific application requirements, ensuring optimal heating efficiency. The manufacturing process involves a specialized firing process at temperatures exceeding 400°C, which imparts unique physical properties to the conductor and resistor materials used in the elements. The final product is a fast, efficient, and reliable heating solution that meets the heating demands of various industries, including automotive, military, and industrial applications.

Stainless Steel-Heating Elements also exhibit excellent thermal efficiency and uniform heating characteristics. They respond quickly to temperature changes while maintaining a stable heating effect. Their corrosion resistance and stability make them ideal for use in high-temperature, humid, or corrosive environments. Whether in complex industrial manufacturing processes, automotive engine heating systems, or military equipment, these heating elements provide reliable solutions that ensure efficient operation and safety.

Substrates of Stainless Steel-Thick Film Heating Elements :

● Stainless Steel-Thick Film Heating Elements consist of a dielectric layer, resistor layer, conductor traces, and a protective coating printed on a stainless steel substrate using screen-printing technology and cured at elevated temperatures. The resultant heater is a high-performance solution that is compact, lightweight, and capable of rapidly and efficiently generating heat.

● Stainless Steel-Thick Film Heating Elements offer excellent thermal conductivity and corrosion resistance due to the use of stainless steel as the substrate material. This combination of features makes them ideal for a wide range of applications where reliable and efficient heating is required in a compact form factor. Standard substrates are usually available in the following models (which can also be customized):

SUS304 Stainless Steel

● Dimension : ø10 - 150mm,t 0.5 - 2.5mm

● Details of contents : Ni 8.0~10.5, Cr 18.0~22.0, Mn 2.0MAX, Fe Bal。

● Proper environment : Air heating,Kettle heating plate。

● Limit service temperature : 400°C or less。

SUS430 Stainless Steel

● Dimension : ø10 - 150mm,t 0.5 - 2.5mm

● Details of contents : Ni ≦ 0.60, Cr 16.0~18.0, Mn 1.0MAX, Fe Bal.

● Proper environment : Air heating,Kettle heating plate.

● Limit service temperature : 400°C or less.

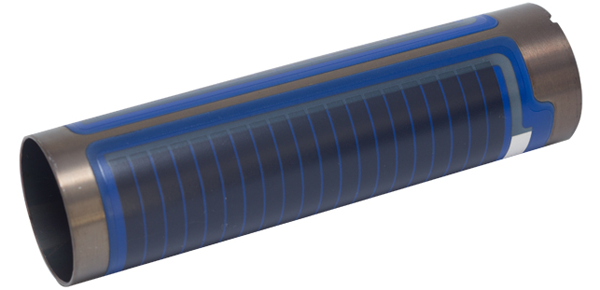

● Stainless Steel-Thick Film Heating Elements are suitable for a variety of applications such as steam generation, grills & griddles, packaging lines, 3D printing and many others. Stainless steel-heating elements are capable for applications that need high temperatures of up to 840 °F (450 °C). The heaters can be applied to complex shapes to generate targeted heat. The heat flux (watt density) can be as high as 200 W/in² (31 W/cm²).

Advantages of Stainless Steel-Thick Film Heating Elements :

1, High-Temperature Capability: These heating elements can operate at temperatures up to 700°C, making them suitable for high-temperature requirements in industrial processes.

2, High Compression Strength: The stainless steel substrate provides excellent compression strength, ensuring durability and reliability under varying conditions.

3, Exceptional Hardness and Wear Resistance: Stainless steel heating elements are very hard and resistant to wear, resulting in long-term performance and minimal maintenance requirements.

4, Superior Material Flexibility and Bend Strength: The material used in these heating elements offers flexibility and bend strength, allowing for customized shapes and configurations to fit specific applications.

5, Versatile Size and Shape Capability: Stainless steel heating elements can be manufactured in various sizes and shapes to accommodate different heating requirements and spatial constraints.

6, Precise and Repeatable Patterning: These elements enable precise and repeatable patterning with distributed wattage, ensuring uniform heat distribution and optimized performance.

7, Temperature Sensor Integration: They can integrate temperature sensor systems into the design, allowing for accurate temperature control and seamless integration with other systems.

8, Highly Efficient with High Thermal Power Density: Stainless steel heating elements are highly efficient, offering a high thermal power density for rapid and effective heat generation.

9, Fast Reaction Times: Due to their low thermal mass, these heating elements have fast reaction times, resulting in quick heating and response to temperature changes.

10, Uniform Heat Distribution: They provide homogeneous and targeted heat distribution, ensuring consistent heating across the surface area.

11, Space-Efficient Installation: Stainless steel heating elements require minimal space for installation, making them ideal for applications where space is limited or needs to be optimized.

Appilcations of Stainless Steel-Heating Elements :

1, Industrial Heating Processes: These heating elements are widely used in industrial ovens, furnaces, and heat treatment equipment due to their high-temperature capability, uniform heat distribution, and rapid response times.

2, Food Processing Equipment: In the food industry, stainless steel heating elements are utilized in cooking appliances, food warmers, and commercial kitchen equipment, where hygiene, durability, and precise temperature control are essential.

3, Medical and Laboratory Equipment: They are employed in medical sterilization equipment, incubators, and laboratory ovens, where reliable, uniform heat distribution and precise temperature control are critical for maintaining optimal operating conditions.

4, Aerospace and Defense: Stainless steel heating elements are used in applications such as aircraft de-icing systems, aerospace testing equipment, and military devices, benefiting from their high compression strength, corrosion resistance, and reliability under extreme conditions.

5, Automotive Industry: These heating elements are integrated into automotive systems for applications like seat heaters, fluid heating, and climate control systems, leveraging their durability, efficient heat transfer, and compact design.

6, Semiconductor and Electronics Manufacturing: They find use in semiconductor processing equipment, soldering systems, and electronics production, providing precise and controlled heating for various manufacturing processes.

7, Energy Generation and Renewables: Stainless steel heating elements play a role in energy generation systems, including solar panels, wind turbines, and geothermal applications, where they provide consistent and reliable heat in challenging environments.

8, Plastics and Rubber Processing: They are applied in extrusion and molding equipment for plastics and rubber processing, offering efficient and uniform heat transfer for shaping and forming processes.

9, Pharmaceutical and Biotechnology: These heating elements are utilized in pharmaceutical production, bioreactors, and drug manufacturing, ensuring precise temperature control and sterile conditions.

10, Commercial and Residential Appliances: Stainless steel heating elements are found in various consumer appliances such as coffee makers, water heaters, and electric stoves, delivering reliable and efficient heat for everyday use.

Manufacturing Challenges of Stainless Steel-Heating Elements :

1, Stress Management:

● Challenge: Thick film technology can introduce stress into the heating element, which may lead to delamination, cracking, or reduced performance over time.

● Overcoming: Stress can be managed by carefully controlling the printing process, using materials with matching thermal expansion coefficients, and employing stress-relief processes.

2, Uniformity of the Thick Film:

● Challenge: Achieving a uniform thick film layer is critical for consistent heating and performance.

● Overcoming: This is addressed through precise screen-printing techniques, proper selection of paste viscosity, and maintaining uniform substrate surface conditions.

3, Adhesion to the Substrate:

● Challenge: Ensuring strong adhesion between the thick film and the stainless steel substrate is essential to prevent peeling or delamination.

● Overcoming: Surface treatments such as cleaning, etching, or the use of adhesion promoters can improve the bond between the film and the substrate.

4, Environmental Stability:

● Challenge: The thick film heating elements must remain stable and functional in various environmental conditions, including exposure to moisture, chemicals, and temperature fluctuations.

● Overcoming: The choice of thick film materials with high environmental stability and the application of protective coatings can enhance the stability of the elements.

5, Temperature Control and Uniformity:

● Challenge: Maintaining a uniform temperature across the heating element can be challenging, especially in large or complex shapes.

● Overcoming: Design optimization, including the use of thermal modeling and simulation, can help in achieving uniform temperature distribution.

6, Material Compatibility:

● Challenge: The choice of thick film materials must be compatible with the stainless steel substrate to ensure long-term reliability.

● Overcoming: Material selection should be based on extensive compatibility testing and understanding the thermal and chemical properties of both the thick film and the substrate.

7, Electrical Resistivity and Power Handling:

● Challenge: The resistive materials used in thick film technology must handle the required electrical power without overheating or failing.

● Overcoming: Using materials with appropriate resistivity and thermal conductivity, and designing the heating element to distribute the power load evenly, can mitigate this challenge.

8, Reliability and Longevity:

● Challenge: Ensuring the long-term reliability of the thick film heating elements is critical for many applications.

● Overcoming: Rigorous testing, including accelerated aging tests and thermal cycling, can help validate the longevity of the elements.

For more information, Please refer to Thick Film Heating Elements.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters