Ceramic-Thick Film Heating Elements

Ceramic-Thick Film Heating Elements, also called Thick Film-Ceramic Heating Elements, based on thick-film technology, are efficient and reliable heating components made from high-performance ceramics such as alumina (Al2O3), aluminum nitride (AlN), and beryllium oxide (BeO), offering excellent thermal stability, electrical insulation, and corrosion resistance, with ceramic substrates providing superior resistance to deformation at high temperatures, a low coefficient of thermal expansion to prevent issues in harsh environments, and electrical insulation properties that reduce the risk of electrical faults, while thick-film technology ensures precise control over the resistor layer for stable operation in high-temperature, high-load applications.

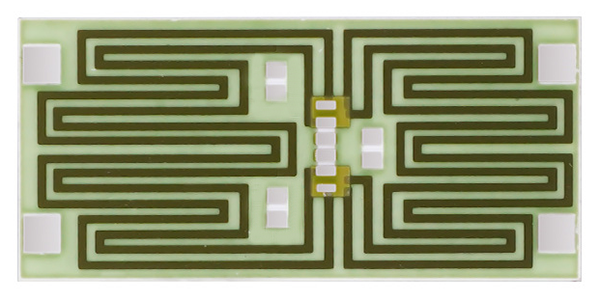

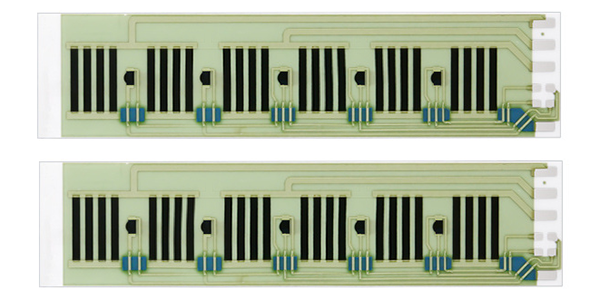

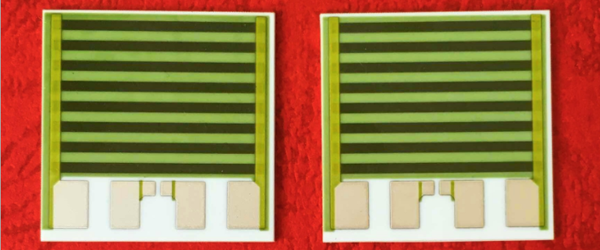

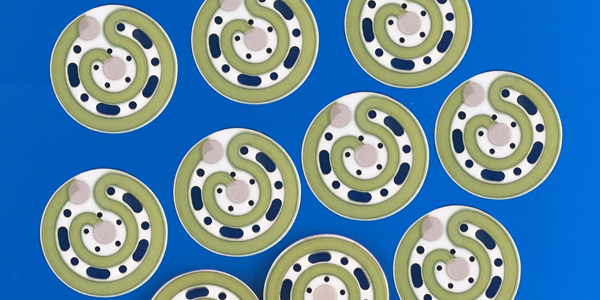

Ceramic-Thick Film Heating Elements are highly customizable, offering significant flexibility in design. Through thick-film technology, manufacturers can precisely control the thickness, width, and distribution of the resistor layer, allowing for the fine-tuning of the heating element’s power, power density, and heating speed. This flexibility makes it possible to create tailored solutions for various customer requirements. Whether it’s for small appliances requiring precise temperature control or high-power industrial heating systems, Ceramic-Thick Film Heating Elements can meet a wide range of complex application needs, ensuring optimal performance for each specific use.

Thick Film-Ceramic Heating Elements are widely used in industries such as manufacturing, healthcare, electronics, and home appliances. In industrial settings, they are commonly employed in high-temperature heating systems; in medical equipment, they provide accurate temperature control; and in home appliances, they are found in heating devices, water heaters, and more. With their exceptional thermal energy conversion efficiency, durability, and high performance, Ceramic-Thick Film Heating Elements have become an essential heating solution in various industries, consistently delivering reliable and efficient heating services across multiple applications.

Features of Ceramic-Thick Film Heating Elements :

1, Customizable Heating Patterns: These elements can be tailored to specific applications, allowing for precise control over heat distribution and power density.

2, Thermal Uniformity: They provide even heat distribution across a surface, ensuring consistent temperature levels for efficient heating.

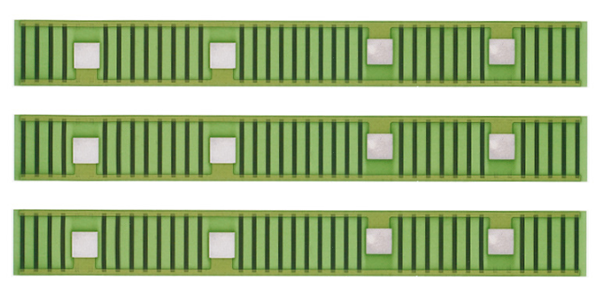

3, Ultra-Thin Design: With the resistive and conductive layers screen-printed directly onto ceramic substrates, these heating elements have a slim profile, making them ideal for space-constrained environments.

4, Advanced Heating Technology: The use of ceramic materials such as alumina, aluminum nitride, and beryllium oxide results in high-performance heating components with superior thermal properties.

5, Targeted Power Delivery: The elements can deliver varying power densities in different areas, allowing for specific heat requirements to be met within an application.

Ceramic Thick Film Heating Elements offer versatility, efficiency, and precision in heating applications, making them suitable for a wide range of industrial and commercial uses.

How Ceramic-Thick Film Heating Elements Work ?

● Ceramic Thick Film Heating Elements operate based on the principle of resistive heating, utilizing the passage of an electric current through a conductor to generate heat. These elements can be categorized into two main types: Radiant Ceramic Heaters and Convective Ceramic Heaters, each functioning uniquely with distinct characteristics.

● The superior thermal conductivity of ceramic materials stems from their high resistance to electrical current. In the construction of Ceramic Thick Film Heating Elements, metal coils are employed with a ceramic substrate sandwiched between them. When an electric current flows through the metal coils, heat is generated and transferred to the ceramic plates. Subsequently, the ceramic material absorbs this heat and releases it into the surrounding air.

● As the air circulates around the Ceramic Thick Film Heating Element, it warms up efficiently due to the heat emitted from the ceramic substrate. This process not only ensures consistent and uniform heating but also enhances the overall thermal efficiency of the element. Furthermore, as water molecules attempt to permeate through the ceramic substrate, additional heat is generated, contributing to the overall heating capacity of the element.

Types of Ceramic-Thick Film Heating Elements :

1, Radiant Ceramic Thick Film Heating Elements:

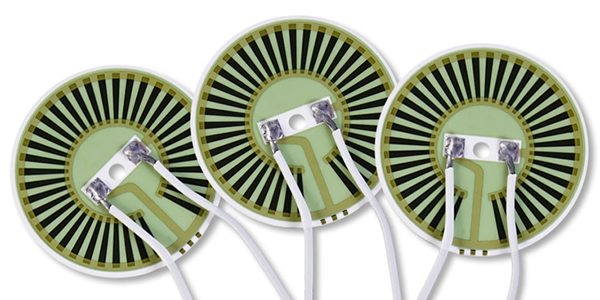

Radiant ceramic thick film heating elements are widely recognized for their superior heat distribution compared to electric or oil-filled radiators. These elements function by using electricity to heat the ceramic plate without the aid of a fan for air circulation. Instead of emitting heat into the surrounding air, the thick film heating element directly absorbs heat through contact with objects in its vicinity. While it may not uniformly disperse heat throughout the space like convection heaters, it effectively retains heat within objects for longer durations.

2, Convective Ceramic Thick Film Heating Elements:

Convective ceramic thick film heating elements are commonly employed in convection heating applications. In this heating method, electricity heats a series of aluminum components (referred to as fins), which subsequently transfer heat to a ceramic thick film heating element. Most convection heaters incorporate a fan to facilitate the rapid circulation of heated air within the room. This arrangement expedites the overall distribution of warmth throughout the space. Additionally, the fan draws in cool air from the base of the heating element, propelling it over the ceramic element and metal components, thereby heating the air and dispersing it throughout the area.

Advantages of Thick Film-Ceramic Heating Elements :

● Exceptionally High Temperature Capability: With the ability to reach temperatures up to 700°C, Thick Film Ceramic Heating Elements provide reliable and consistent high-temperature heating solutions for diverse industrial processes.

● High Compression Strength: The robust construction of Thick Film Ceramic Heating Elements ensures high compression strength, making them durable and long-lasting even under demanding operating conditions.

● Superior Hardness and Wear Resistance: The inherent hardness and wear resistance of ceramic materials ensure prolonged lifespan and minimal maintenance requirements, contributing to cost-effective heating solutions.

● Enhanced Material Flexibility and Bend Strength: Thick Film Ceramic Heating Elements exhibit superior material flexibility and bend strength, allowing for versatile and customized heating element designs to suit specific application requirements.

● Excellent Size and Shape Flexibility: These heating elements offer excellent size and shape capabilities, enabling precise tailoring to fit various heating profiles and spatial constraints.

● Precise and Repeatable Wattage Distribution: The advanced technology used in ceramic thick film heating elements allows for precise and repeatable wattage distribution across the heating surface, ensuring uniform heating performance.

● Integrated Temperature Sensor System: Ceramic thick film heating elements can be equipped with temperature sensor systems that seamlessly integrate into other control systems, offering enhanced monitoring and regulation capabilities.

● Highly Efficient Thermal Power Density: These heating elements boast high thermal power density, providing efficient heat transfer and rapid response times for optimized heating processes.

● Fast Reaction Times: Due to their low thermal mass, ceramic thick film heating elements exhibit fast reaction times, delivering quick and precise heating output as needed.

● Space-Efficient Installation: With minimal space requirements for installation, Thick Film Ceramic Heating Elements offer a compact heating solution ideal for applications where space is limited.

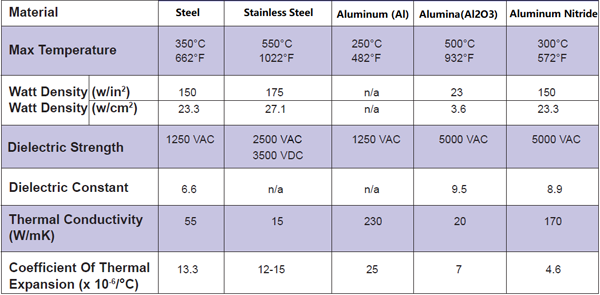

Substrates of Ceramic-Thick Film Heating Elements :

Design Considerations of Thick Film-Ceramic Heating Elements :

● Substrate Material Selection: The substrate material should have high mechanical strength and good thermal insulation properties. Common substrate materials include ceramics such as aluminum oxide (Al2O3) and aluminum nitride (AlN), known for their excellent thermal stability and electrical insulation.

● Thermal Conductivity: The thermal conductivity of the substrate is crucial for heat dissipation and should be tailored to the application's requirements.

● Resistive Material Properties: The resistive material used for the heating element should have stable resistivity over the operating temperature range and should be compatible with the substrate material.

● Heating Element Configuration: The design of the heating element, including its shape and size, affects the heat distribution and power density. The configuration should be optimized for uniform heating and rapid thermal response.

● Operating Temperature: The maximum operating temperature of the heating element must be determined and should not exceed the thermal limits of the materials used.

● Power Requirements: The power density and total power requirements will influence the design, as higher power densities may require additional thermal management strategies.

● Environmental Conditions: The heating element must be able to operate in the intended environmental conditions, which could include exposure to moisture, chemicals, or mechanical stress.

● Reliability and Durability: The design should ensure long-term reliability and durability, with consideration given to the number of heating cycles the element will undergo.

● Safety Considerations: Safety features such as over-temperature protection and fault monitoring may need to be integrated into the design.

● Manufacturability: The design should be compatible with the manufacturing processes, such as screen printing and firing cycles, to ensure reproducibility and cost-effectiveness.

● Customization: As applications for ceramic thick film heating elements can be diverse, the design may need to be customized to fit specific application requirements, such as shape, size, and power output.

● Regulatory Compliance: The design must comply with relevant industry standards and regulations, particularly if used in medical, aerospace, or other highly regulated fields.

● Thermal Expansion Coefficient: The material's thermal expansion coefficient should be considered to prevent mechanical stress and failure due to thermal cycling.

● Uniform Heating: The heater design should aim to produce uniform heating across the active area without hotspots, which can be achieved by varying the resistance and using high thermal conductive layers.

● Mechanical Stability: The substrate should be capable of withstanding the maximum temperature for the intended applications without significant deformation.

● Response Time: A short response time is desirable for efficiency and to reduce power consumption, which can be achieved through careful design and selection of materials.

For more information, Please refer to Thick Film Heating Elements.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters