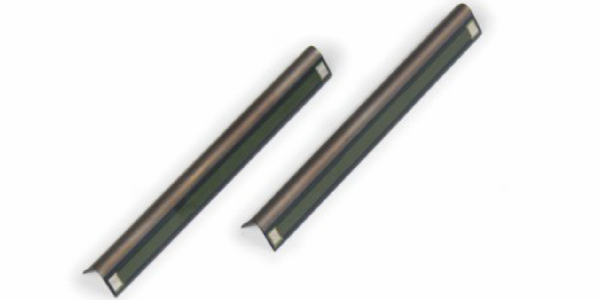

Optical Fibre Fusion Splicer-Heating Elements

Optical Fibre Fusion Splicer-Heating Elements are cutting-edge components specially designed for splicing machines used in optical fibre communication systems, typically utilizing stainless steel or ceramic as substrates, and combined with thick film heating technology to manufacture the core heating elements, enabling efficient and reliable heat generation for seamless fibre fusion.

Optical Fibre Fusion Splicer-Heating Elements are essential components in optical fibre splicing machines, designed to deliver precise and controlled heat for the fusion of fibre ends. Made from high-quality materials like stainless steel or ceramic, these elements use advanced thick film heating technology to generate efficient heat, ensuring minimal signal loss and reliable performance. They play a crucial role in creating permanent optical connections by melting fibre ends and ensuring high-quality splices without damaging the fibres.

Optical Fibre Fusion Splicer-Heating Elements are built for durability, energy efficiency, and long-term reliability. Designed to withstand high temperatures during fusion, they minimize power consumption while maintaining consistent performance. With advanced thermal management systems, these heating elements are ideal for use in various settings, such as telecommunications, data centers, and fibre optic networks. Their versatility allows them to work with different fibre types, making them a reliable choice for both field and factory splicing applications.

Features of Optical Fibre Fusion Splicer-Heating Elements :

● Efficiency: The heating element delivers rapid and uniform heat distribution, ensuring quick and precise fusion splicing of optical fibres.

● Reliability: With its robust design and high-quality materials, the element offers consistent performance and durability over extended usage.

● Energy Efficiency: By leveraging thick film heating technology, the element maximizes energy utilization, reducing power consumption during fusion splicing operations.

● Versatility: Compatible with various fusion splicer models, the element provides flexibility and ease of integration into different optical fibre splicing systems.

● Precision Control: The element enables precise temperature control, facilitating optimal fusion splicing conditions for enhanced splice quality.

Why Used Thick Film Heating Element Technology For Optical Fibre Fusion Splicer ?

● Efficient Heat Transfer: Thick film paste on the substrate offers excellent thermal conductivity, promoting efficient heat transfer and uniform heating across the splicing area.

● Customizable Heating Patterns: Thick film can be precisely printed to create specific heating patterns, allowing for tailored heat distribution as needed for optimal fusion splicing results.

● Reliability and Durability: Thick film heating elements are known for their reliability and longevity, ensuring consistent performance over an extended lifespan.

● Energy Conservation: By generating heat directly where it is needed, the thick film heating element minimizes heat loss and energy wastage, contributing to overall energy efficiency in fusion splicing processes.

Optical Fibre Fusion Splicer-Heating Element stands out as a superior heating solution for modern optical fibre fusion splicing applications, offering unmatched performance, efficiency, and reliability for seamless splicing operations.

For more informations, Please refer to Thick Film Heating Element.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters