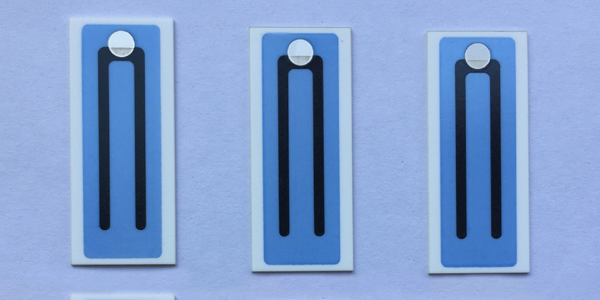

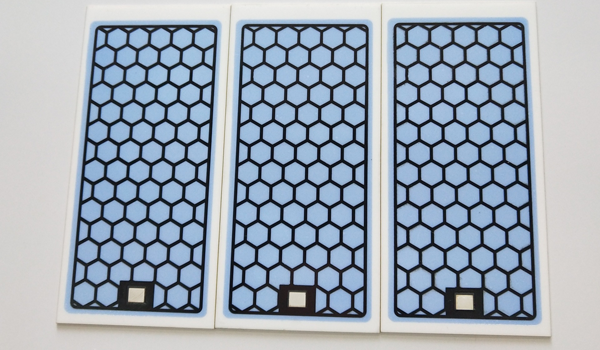

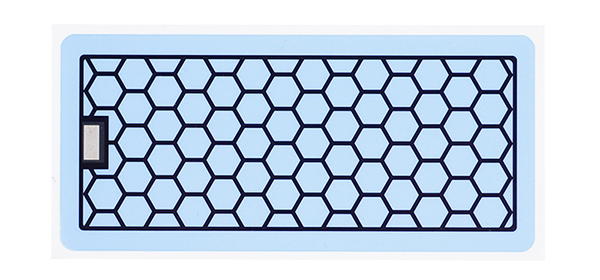

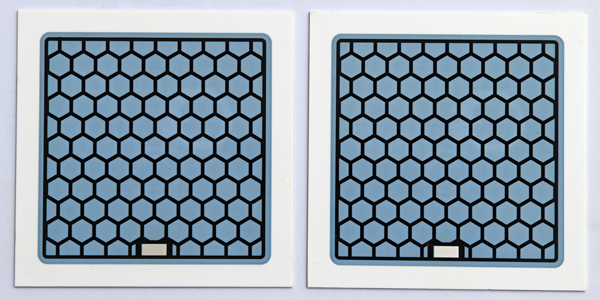

Ozone Generator-Ceramic Plates

Ozone Generator-Ceramic Plates, also called Ozone Generator-Ceramic Sheets, are core components of air purification devices manufactured using ceramic thick-film technology, where materials such as silver-palladium (electrodes) and carbon film (high-value resistors) are printed onto ceramic substrates and formed through high-temperature sintering processes. With their compact structures and stable performance, they efficiently generate ozone, effectively removing odors, harmful gases, bacteria, viruses, and other pollutants from the air, making them indispensable key elements in efficient and eco-friendly equipment.

Ozone Generator-Ceramic Plates serve as a key part of the ozone generator system, acting as a dielectric or insulator. During operation, they facilitate the conversion of regular oxygen (O2) molecules into ozone (O3) through the application of an electric field. Ozone molecules contain an additional oxygen atom, giving them strong oxidative properties that allow them to break down bacteria, viruses, harmful gases, and organic substances, thereby purifying and disinfecting the air.

Ozone Generator-Ceramic Sheets are known for their high ozone generation efficiency, stable performance, and long service life. These characteristics make them indispensable core components in air purification equipment, industrial exhaust treatment, wastewater treatment, food preservation, and many other applications.

Features of Ozone Generator-Ceramic Plates :

● Dielectric Strength: Ozone Generator-Ceramic Plates are made from materials like alumina (Al2O3), which provide high dielectric strength, enabling them to withstand the high voltage required for ozone production without breaking down.

● Heat Resistance: Due to their composition, ceramic plates can endure the heat generated during the ozone generation process, maintaining their structural integrity and performance.

● Chemical Stability: Ceramic materials are chemically inert and resistant to corrosion, which is essential as ozone is a powerful oxidant and can react with more reactive materials.

● High Purity: The ceramic used in ozone plates is of high purity, which is critical for ensuring the efficiency and purity of the ozone produced.

● Customizability: Ceramic plates can be manufactured to meet specific application requirements, including different sizes, shapes, and designs to fit various ozone generator models and applications.

● Long Service Life: Under proper maintenance and operating conditions, ceramic ozone plates can have a long service life, with some manufacturers offering lifespans of thousands of hours.

● Efficient Ozone Production: The design of the ceramic plate, including the discharge gap, contributes to efficient ozone production. A narrow(discharge gap) of less than 0.2mm can improve micro discharge density and heat dissipation, enhancing ozone yield.

● Safety: When used correctly, ceramic ozone plates contribute to a safe ozone generation process. However, it's important to follow safety guidelines and ensure that ozone generators are used in unoccupied spaces to prevent health issues associated with high concentrations of ozone.

● Low Maintenance: With their robust construction, ceramic plates require minimal maintenance. However, periodic cleaning may be necessary to ensure optimal performance and longevity.

● Compatibility with High-Frequency Power Supplies: Modern ozone generators often use high-frequency power supplies, and ceramic plates are designed to work efficiently with these systems, which can result in energy savings and improved ozone generation efficiency.

● Environmental Considerations: Ceramic plates do not contribute to environmental pollution as they are made from natural materials and do not produce harmful by-products during the ozone generation process.

● Versatility: Ozone Generator-Ceramic Plates are used in a wide range of applications, from air and water purification to medical and industrial processes, showcasing their versatility and reliability.

Operating Principle of Ozone Generator-Ceramic Plates :

● High Voltage Discharge: Ozone Generator-Ceramic Plates are used as a dielectric medium in the ozone generation process. When a high voltage is applied across the ceramic plate, it creates a strong electric field between two electrodes that are in close proximity to the plate.

● Oxygen Conversion: Oxygen molecules (O2) from the air or pure oxygen gas are passed through the electric field created by the ceramic plate. The high-energy electrons in the field ionize the oxygen molecules, breaking them apart into individual oxygen atoms (O).

● Ozone Formation: The free oxygen atoms then react with other oxygen molecules to form ozone (O3), a molecule consisting of three oxygen atoms. Ozone is a potent oxidant with various applications, including air and water purification.

● Heat Management: Due to the exothermic nature of the reaction, heat is generated during the process. Ceramic plates are designed to withstand these temperatures and may include features to help dissipate heat, ensuring the stability and longevity of the ozone generation process.

● Efficiency and Safety: The ceramic material's properties, such as its high dielectric strength and chemical inertness, contribute to the efficiency and safety of the ozone generation system. It prevents electrical breakdown and resists the corrosive effects of ozone.

● Maintenance: Although ceramic plates are robust, they may require periodic cleaning to remove any accumulated prints that could reduce the efficiency of ozone production over time.

Application of Ozone Generator-Ceramic Sheets :

● Air Purification: Ozone is used to eliminate odors and purify the air by oxidizing volatile organic compounds (VOCs) and inactivating airborne bacteria and viruses. This application is common in residential, commercial, and industrial settings.

● Water Treatment: Ozone is highly effective for disinfecting water by killing bacteria, viruses, and other pathogens without leaving harmful residues. Ceramic plates are used in ozone generators that treat drinking water, wastewater, and water in swimming pools.

● Medical Applications: In healthcare facilities, ozone is used for sterilization of surfaces and equipment, as well as for the treatment of certain medical conditions due to its antimicrobial properties.

● Food Industry: Ozone is used to sanitize food processing equipment, extend the shelf life of fresh produce, and decontaminate fruits and vegetables by eliminating bacteria and other microorganisms.

● Waste Treatment: Ozone generation is used to reduce odors and neutralize harmful substances in waste treatment facilities.

● Agriculture: Ozone can be used for soil treatment and water purification in agriculture, helping to control pests and diseases without the use of harsh chemicals.

● Disinfection in Aquariums: Ozone is used to kill bacteria and other microorganisms in aquarium water, improving the health of fish and reducing the need for chemical additives.

● Industrial Oxidation: In industrial processes, ozone is used for the oxidation of certain chemicals and in the production of various chemicals and materials.

● Surface Disinfection: Ozone can be used to disinfect surfaces in laboratories, hospitals, and food processing plants.

● Environmental Remediation: Ozone is used to break down pollutants and contaminants in soil and water for environmental cleanup.

● Cosmetics Industry: Ozone is used for the purification of air and water in the production of cosmetics to ensure a sterile environment.

● Textile Industry: Ozone treatment can remove impurities and odors from fabrics, improving the quality of textiles.

For more information, Please refer to Thick Film Heaters.

Custom Thick Film Heaters

- Custom Thick Film Heating Elements

- Thick Film Heating Solutions

- Ceramic-Thick Film Heaters

- Stainless Steel-Thick Film Heaters

- Polyimide Heaters (PI Heaters)

- Polyester Heaters (PET Heaters)

- Flexible Heaters

- Mica Heaters

- Flexible Heating Elements

- Thick Film Tubular Heaters

- Ceramic Ozone Plates

- Thermosensitive-Ceramic Heating Elements

- Hair Straightener-Thick Film Heaters

- Vacuum Packer-Thick Film Heaters

- Optical Fibre Fusion Splicer-Heating Elements

- E-Cigarettes Heaters

- Laser Printer-Thick Film Heaters