High Energy Ceramic Resistors

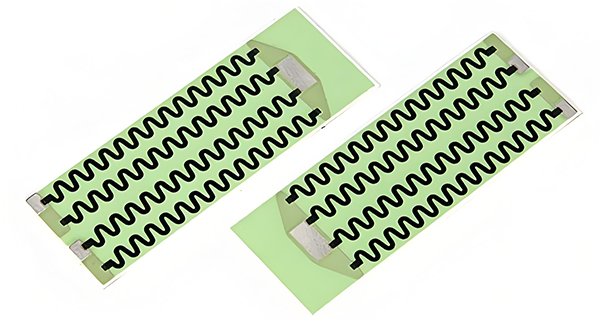

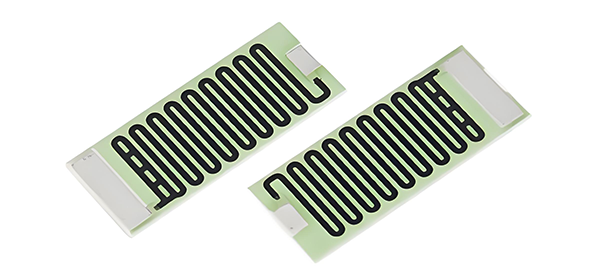

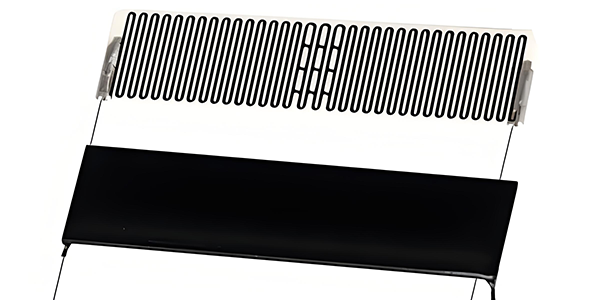

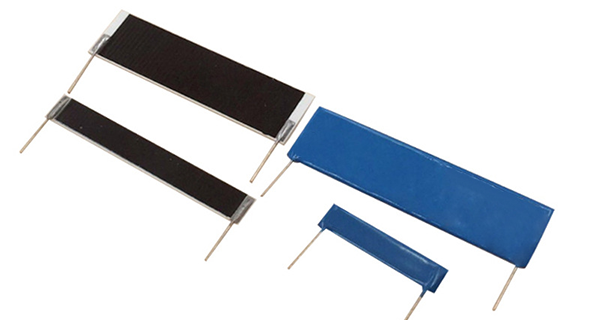

High Energy Ceramic Resistors, also called Ceramic High Energy Resistors, are a specialized type of resistor that combines thick film technology with ceramic substrates, designed to operate in high-energy environments and capable of handling significant power and energy densities, typically made from materials with high thermal conductivity to ensure effective heat dissipation under high-energy loads, and compared to traditional thin-film resistors, these resistors are structurally more robust, providing higher reliability and a longer lifespan under harsh operating conditions.

High Energy Ceramic Resistors are designed to provide reliable performance in high-power applications, featuring high power handling, excellent thermal management, and durability. Their primary function is to convert electrical energy into heat and manage it effectively to ensure consistent and reliable operation. These resistors are built to withstand high-energy loads, with superior thermal dissipation properties that prevent overheating and ensure long-term use. Compared to standard resistors, High Energy Ceramic Resistors offer better thermal stability, mechanical strength, and the ability to endure extreme conditions, making them ideal for environments with high thermal stress and power fluctuations.

Ceramic High Energy Resistors are widely used in industries that require high power handling and exceptional reliability. They are commonly found in applications such as power supplies, electric vehicles, industrial machinery, and military equipment, where reliable performance under demanding conditions is essential. Additionally, they are used in high-energy environments like motor drives, welding equipment, and renewable energy systems, where power dissipation and durability are critical. Their ability to maintain consistent performance in high-temperature and high-power scenarios makes them indispensable in applications requiring continuous operation and resilience against harsh operating conditions.

Features of High Energy Ceramic Resistors :

High Energy Ceramic Resistors are designed to handle high power and energy densities in demanding environments, offering several key features:

● High Power Handling: These resistors are engineered to withstand significant power loads without compromising performance. Their design allows them to manage high energy input efficiently, making them ideal for power applications.

● Excellent Thermal Management: High Energy Ceramic Resistors are made from materials with high thermal conductivity, which ensures that the heat generated during operation is dissipated effectively. This prevents overheating and ensures that the resistors maintain reliable performance even in high-temperature environments.

● Durability and Reliability: Built to endure harsh conditions, these resistors are more durable than standard resistors, offering a longer lifespan. They are resistant to physical stress, thermal shock, and other environmental factors, making them reliable for long-term use in challenging conditions.

● Robust Construction: Compared to traditional thin-film resistors, High Energy Ceramic Resistors feature a thicker, more robust structure that provides superior mechanical strength. This added toughness allows them to function well in industrial, automotive, and military applications, where resilience is crucial.

● Customizability: These resistors can be tailored to specific applications, offering flexibility in size, resistance values, power ratings, and other specifications, allowing them to meet a wide range of requirements across different industries.

● Consistent Performance: Designed to maintain steady operation under high power and energy conditions, these resistors offer consistent and stable performance throughout their lifespan, even in the most demanding scenarios.

These features make High Energy Ceramic Resistors suitable for a wide variety of high-power, high-reliability applications, ranging from industrial equipment to renewable energy systems and electric vehicles.

Working Principle of High Energy Ceramic Resistors :

● High Energy Ceramic Resistors operate based on the resistive properties of the materials used in their construction. The resistive element is typically made from a thick layer of conductive material, such as a metal or a conductive ceramic compound. When an electric current passes through this layer, the resistance offered by the material converts some of the electrical energy into heat, in accordance with Ohm's Law (V = IR). The key to their operation at high energies is the effective management of this heat through the resistor's design and material properties, ensuring that the heat generated does not damage the resistor or affect its performance.

● High Energy Ceramic Resistors operate based on the principle of converting electrical energy into heat energy through resistance. When an electrical current passes through the resistor, the resistor material opposes the flow of current, causing electrical energy to be transformed into heat. This heat is then dissipated through the ceramic substrate, which is made of materials with high thermal conductivity to ensure efficient heat transfer.

● The resistor's performance is primarily determined by the properties of the materials used in its construction. The ceramic substrate acts as an excellent heat sink, preventing the resistor from overheating and ensuring stable performance even under high-energy loads. The thick-film technology used in these resistors creates a durable and robust layer of resistance material, which increases the overall power handling capacity.

● In operation, the resistor's ability to manage both the electrical energy and the heat generated is key to its effectiveness. By using materials with superior heat dissipation characteristics, High Energy Ceramic Resistors can handle significantly higher power levels than standard resistors. This ensures that they can operate efficiently in high-power applications without failure, maintaining their functionality over extended periods even in harsh environments.

Applications of Ceramic High Energy Resistors :

● Power Electronics: Ceramic High Energy Resistors are integral in power converters, inverters, and high-power amplifiers where both high current and voltage are involved. They provide efficient power management by handling high energy loads and ensuring stable operation in demanding conditions.

● Pulsed Power Systems: Ceramic High Energy Resistors are essential in systems that require the rapid delivery of high-energy pulses, such as radar systems, medical equipment (e.g., defibrillators), and particle accelerators. They help manage the extreme energy demands and ensure reliable performance under fast, intense pulses.

● Military and Aerospace: In military and aerospace applications, where reliability and the ability to withstand extreme conditions are paramount, Ceramic High Energy Resistors are used in satellite systems, military communication equipment, and avionics. Their robustness makes them ideal for harsh environments, including high temperatures, vibrations, and radiation.

● Industrial Control Systems: Ceramic High Energy Resistors are commonly found in motor drives, power supplies, and process control systems in industrial settings. They play a critical role in applications that demand high energy resistance, precision, and the ability to withstand continuous operation under variable loads.

● RF and Microwave Systems: In radio frequency (RF) and microwave applications, Ceramic High Energy Resistors are used to control and dissipate the high energy levels associated with these frequencies. They are essential in the design of components like attenuators, power dividers, and load resistors, ensuring efficient energy management in communication systems.

● Energy Storage and Conversion: Ceramic High Energy Resistors are also utilized in energy storage and conversion systems, such as battery management systems and renewable energy applications like solar and wind power. They help manage energy flows and dissipate excess energy, improving the efficiency and lifespan of energy storage devices and ensuring safe operation.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors