Custom Thick Film Resistor Elements

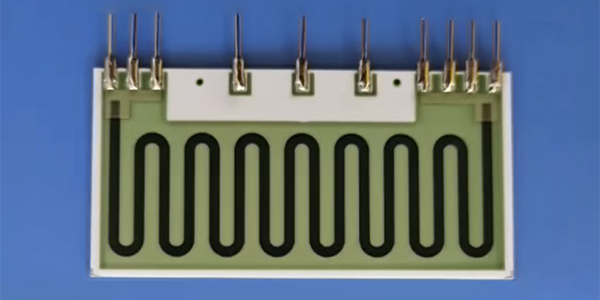

Custom Thick Film Resistor Elements are passive resistor components custom-made using thick film technology combined with ceramic substrates, with the primary function of controlling the electrical performance of circuits by limiting or regulating current; the manufacturing process typically involves printing the resistor material in the form of a thick film onto a ceramic substrate, creating resistor elements with specific resistance values and power handling capabilities, and these components can be precisely designed and produced according to the customer's specific requirements, such as size, resistance, power, and function, to meet different electrical specifications.

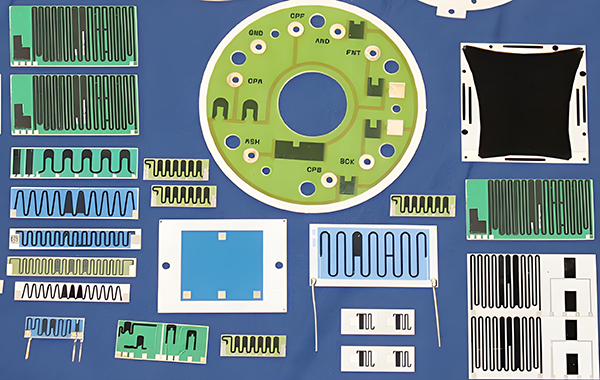

Custom Thick Film Resistor Elements offer high customization and a variety of functions. Depending on design requirements, different types of thick film resistors can be provided, such as high-value resistors, high-power resistors, high-voltage resistors, non-inductive resistors, variable resistors, and more. These resistors can be produced in various sizes and shapes and optimized based on current carrying capacity, operating environment, and specific functions. For instance, high-power resistors are suitable for high-power circuits, while RF resistors are used for high-frequency signal applications. Additionally, custom thick film resistors can be designed in various structures such as planar, tubular, or network forms to meet the specific needs of different industries and devices.

Custom Thick Film Resistor Elements are widely used in various electronic devices and systems, particularly in situations where precise control of current and voltage is required. They are commonly found in power circuits, communication equipment, automation systems, consumer electronics, medical instruments, and automotive electronics. High-voltage and high-power resistors are typically used in power systems and industrial equipment, while humidity-sensitive resistors are employed in environmental monitoring and sensor applications. Non-inductive resistors are commonly used in RF circuits to avoid high-frequency signal interference, ensuring signal stability and quality. Moreover, the variability of custom thick film resistors makes them crucial in precision circuit adjustments and voltage divider circuits, making them indispensable components in many high-performance electronic devices.

Product Types of Custom Thick Film Resistor Elements :

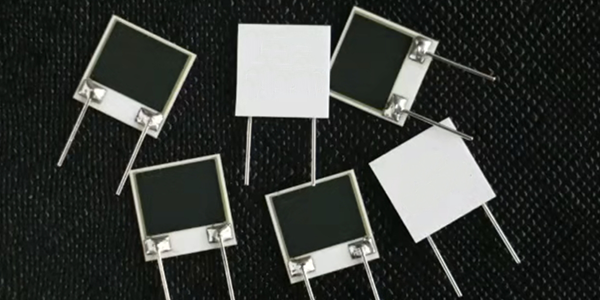

● High Voltage Ceramic Resistors made with thick film technology, resist environmental stressors like moisture, humidity, and temperature fluctuations. They ensure stable voltage and current control, long-lasting performance, and excellent temperature stability in extreme conditions.

● High Value Ceramic Resistors offer high resistance, power handling, and durability for high-energy and high-voltage applications. The ceramic substrate provides thermal stability, while laser trimming ensures precise resistance values and sizes.

● High Energy Ceramic Resistors are designed for high-power applications, converting electrical energy into heat while offering excellent thermal management, durability, and superior thermal dissipation. They excel in extreme conditions, offering better thermal stability and mechanical strength.

● High Power Ceramic Resistors handle large electrical loads with excellent thermal conductivity and stability, preventing overheating. Their durability ensures performance under rapid temperature changes, physical stress, and environmental factors.

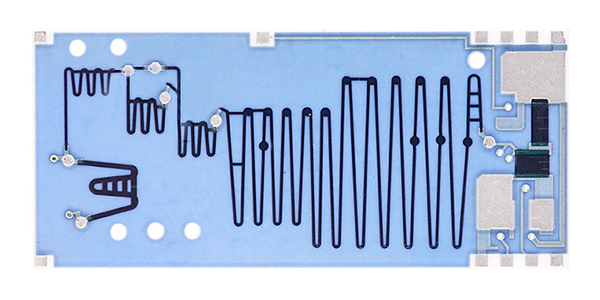

● Thick Film Non-Inductive Resistors offer precise resistance, high power handling, and stable performance without inductance, ideal for high-frequency, high-power applications. Their ceramic or glass substrate provides durability and thermal stability.

● Thick Film Planar Resistors provide high precision, space efficiency, durability, and heat resistance. They are ideal for complex circuits and precise signal processing, handling power dissipation with minimal noise.

● Thick Film Tubular Resistors offer stable resistance, high voltage handling, and heat dissipation in high-power applications. They operate in extreme temperatures and provide precise resistance control for long-term stability.

● Thick Film Resistor Networks integrate multiple resistive values into one component, offering high power handling, durability, and stable performance. Their compact size and customizable resistance make them ideal for space-constrained, cost-efficient applications.

● Humidity Sensitive Ceramic Resistors are precise, reliable, and cost-effective, with fast response times and durability in high-humidity environments. They are simple to manufacture, enabling mass production with screen-printed thick film structures.

● Radio Frequency Power Resistors handle high frequencies, low reflection, and stable resistance. Designed for high power dissipation, they ensure circuit stability and prevent overheating, offering precision across a broad frequency range.

● High Voltage Divider Resistors accurately step down high voltage for measurement or signal processing. Made with ceramic substrates and thick-film technology, they offer precise, stable resistance and withstand high voltages for long-term reliability.

● Ceramic Variable Resistors offer precise adjustments, excellent temperature stability, and durability. They provide strong resistance to environmental factors, ensuring reliable performance in demanding applications requiring fine adjustments.

How to Customize Thick Film Resistor Elements ?

● Identify Application Requirements: The initial step involves discerning the precise needs of the application. This encompasses factors like desired resistance value, tolerance, power rating, and physical dimensions. It's crucial to consider environmental conditions and regulatory standards, particularly in fields like medical device manufacturing.

● Select the Appropriate Material: Choose the resistive element material based on the application's demands. Common options include tungsten, molybdenum, and chromium, which are blended with glass components and sintered at elevated temperatures to form a ceramic base. For medical applications, materials must also be biocompatible and resilient to various agents.

● Determine Resistor Characteristics: Define critical specifications such as temperature coefficient, noise properties, and long-term stability. These attributes are pivotal for ensuring optimal performance in the target application.

● Design Resistor Geometry: Tailor the resistor's geometry, encompassing its shape and dimensions, to fit the application's constraints. In medical contexts, this may involve crafting a resistor suitable for installation within intricate and confined spaces within the device.

● Manufacturing Process: The manufacturing process typically entails screen-printing the resistive material onto a ceramic substrate, followed by sintering to solidify the layer. Additional steps may include applying a protective coating to enhance resistance to corrosion and oxidation.

● Prototyping and Testing: Prior to full-scale production, develop prototypes of the customized resistor and subject them to rigorous testing to ensure compliance with specified requirements. This involves assessments of resistance value, power handling capabilities, and stability across diverse operating conditions.

● Regulatory Compliance: Ensure that the customized resistor adheres to relevant regulations and standards. In medical applications, this may necessitate obtaining certifications and adhering to stringent safety and performance criteria.

● Final Production and Quality Control: Once the design has been validated and regulatory compliance ensured, proceed with final production. Implement a robust quality control regimen to verify that each resistor meets the exacting standards of the customization specifications.

Why Deed to Customize Thick Film Resistor Elements ?

Custom Thick Film Resistor Elements are specialized components that are designed to meet the unique requirements of certain electronic applications. Here are several reasons why one might need to opt for custom thick film resistor elements:

● Specific Tolerance Levels: Standard resistors may not offer the precision required for certain applications. Custom thick film resistor elements can be manufactured to have tighter tolerances, ensuring accuracy in circuit performance.

● Unique Power Ratings: Applications that require handling higher power levels may necessitate resistors with specific power ratings that are not available in standard offerings.

● Specialized Sizes and Shapes: For space-constrained environments or to fit into unique form factors, Customized resistors can be designed with specific dimensions and shapes to fit the application perfectly.

● Material Requirements: Different applications might require resistors made from specific materials to withstand certain environmental conditions, such as high temperatures, corrosive environments, or to meet specific electrical properties.

● High Reliability and Consistency: Custom-made resistors can be manufactured to ensure high reliability and consistency in performance, which is critical for applications where failure is not an option.

● Long-term Availability: Custom thick film resistor elements can be produced in a way that ensures their long-term availability, even if standard equivalents are phased out or become obsolete.

● Regulatory Compliance: Custom thick film resistor elements can be designed to meet specific regulatory standards or industry certifications that are required for certain markets or applications.

● Cost Optimization: While initially more expensive, Custom thick film resistor elements can lead to cost savings in the long run by reducing waste, improving efficiency, and ensuring the longevity of the product.

● Innovative Applications: New and innovative electronic designs may require resistors with unique characteristics that cannot be found in standard products.

● Technical Support and Collaboration: Working with a manufacturer to create custom thick film resistor elements often involves a collaborative process that can lead to better understanding and optimization of the final product.

Custom Thick Film Resistor Elements are chosen when the specifications of off-the-shelf components do not align with the specialized needs of a project, and when the performance, reliability, and longevity of the resistor are paramount.

Specifications of Custom Thick Film Resistor Elements :

● Rated power: 2.5w-20w

● Resistance range: 10 Ω ~ 10G Ω

● Allowable deviation: ± 1% ~ ± 10%

● Temperature coefficient: minimum ± 50ppm (25 ℃ ~ 105 ℃)

● Insulation withstand voltage: > 1000VDC

● Insulation resistance: ≥ 10g Ω

● Working temperature range: - 55 ℃ ~ + 225 ℃

● Maximum working voltage: 48kvdc

● Inductance: non inductive

● Connectors: tinned iron cap

● Resistance installation: Welding

● Overload: 5p value does not exceed 1.5umax5s, Δ R≤±0.2%R

● Service life: rated power 1000h, Δ R≤±0.5%R

● Steady state damp heat: mil-std-202, method 103, condition D, Δ R≤±0.4%R

● Thermal shock: mil-std-202, method 107, condition C, Δ R≤±0.2%R

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors