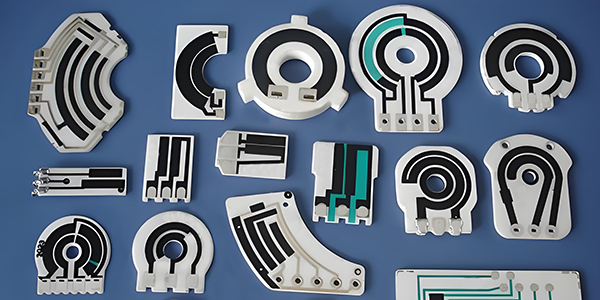

Ceramic Variable Resistors

Ceramic Variable Resistors, also called Thick Film Variable Resistors, are custom-made electronic components that use thick film technology combined with ceramic substrates to provide a method for adjusting and fine-tuning the resistance in a circuit, featuring a ceramic substrate with conductive tracks, a wiper that moves along these tracks to change the resistance, and terminals that connect to the circuit, ensuring precise control and high stability for accurate electrical adjustments.

Ceramic Variable Resistors are known for their high precision, excellent temperature stability, and durability. The thick film technology allows for fine resistance adjustments, ensuring consistency and reliability over long periods of use. These resistors exhibit strong resistance to environmental factors such as high temperatures, humidity, and electromagnetic interference, ensuring reliable performance in harsh conditions. Their customizable nature allows them to be adapted to various circuit requirements, making them suitable for applications that demand fine adjustments and stable outputs.

Thick Film Variable Resistors are widely used across various industries, particularly in consumer electronics, automotive electronics, and industrial control systems. In consumer electronics, they are used in audio equipment, televisions, and power management systems. In automotive electronics, they are integral to components like throttle position sensors, accelerator pedal sensors, and fuel level sensors. In industrial control, they are employed in devices like potentiometers and position sensors to provide accurate control and adjustment capabilities. Due to their exceptional performance and reliability, Ceramic Variable Resistors are a preferred choice in applications requiring high precision and long-term stability.

Features of Ceramic Variable Resistors :

1, High Precision and Accuracy: Ceramic Variable Resistors provide excellent precision in resistance adjustment, allowing for fine-tuning of electrical parameters in a circuit. This makes them ideal for applications where accurate resistance control is crucial.

2, Excellent Temperature Stability: These resistors are designed to operate effectively across a wide range of temperatures, maintaining stable resistance values even under extreme conditions. This feature ensures reliable performance in environments where temperature fluctuations are common.

3, Durability and Longevity: Ceramic Variable Resistors are highly durable and designed to withstand long-term use. Their robust construction ensures they can perform consistently over extended periods, even under harsh operating conditions such as high temperatures, humidity, and vibration.

4, Resistance to Environmental Factors: Due to their thick film construction and ceramic substrate, these resistors offer strong resistance to environmental factors like moisture, dust, and electromagnetic interference. This enhances their reliability in industrial and automotive applications.

5, Customizable and Versatile: Ceramic Variable Resistors can be customized to meet specific circuit requirements. They are available in various resistance ranges and sizes, making them versatile for different applications in consumer electronics, automotive systems, and industrial controls.

6, Low Power Consumption: Ceramic Variable Resistors typically exhibit low power loss, making them energy-efficient components in circuits. This feature is particularly beneficial in power-sensitive applications.

7, Compact and Lightweight: Despite their high performance, these resistors are relatively compact and lightweight, making them easy to integrate into a wide range of electronic devices without adding significant bulk.

Applications of Thick Film Variable Resistors :

● Consumer Electronics: Thick Film Variable Resistors are widely used in various consumer electronics, such as audio equipment, televisions, and home appliances, to adjust volume, tone, brightness, and other settings that require fine resistance control.

● Automotive Electronics: These resistors play a crucial role in automotive applications, including throttle position sensors, accelerator pedal sensors, fuel level sensors, and temperature sensors. They help accurately monitor and adjust critical parameters within a vehicle's electrical system.

● Industrial Control Systems: In industrial applications, Thick Film Variable Resistors are used in potentiometers, position sensors, and controllers, providing precise resistance adjustments for machinery and automation systems to ensure accurate control over operations like speed, positioning, and pressure.

● Medical Equipment: These resistors are essential in medical devices, such as diagnostic equipment, patient monitoring systems, and hearing aids, where precise adjustments are necessary for accurate readings and functionality.

● Instrumentation and Measurement Devices: Thick Film Variable Resistors are integral to various measuring instruments, where they are used to calibrate and fine-tune readings, ensuring precise and reliable performance in devices like oscilloscopes, voltmeters, and multimeters.

● Lighting Control: In lighting systems, particularly in dimmer switches and adjustable lighting applications, Thick Film Variable Resistors are employed to provide smooth and precise control over the intensity of light, allowing users to adjust brightness levels effectively.

● Telecommunications: In communication systems, these resistors are used in signal processing equipment, helping to fine-tune signal transmission and maintain optimal performance in devices like amplifiers and transmitters.

● Aerospace and Defense: Thick Film Variable Resistors are also used in specialized applications such as radar systems, satellite communications, and other high-precision instruments in the aerospace and defense industries, where reliable and stable performance is crucial.

How Variable Resistor Works For LP Gas Tank Gauges ?

● Sensing the Fuel Level: Ceramic variable resistor is typically part of a float system inside the LP gas tank. As the level of the gas changes, the float moves up or down along with the fuel level. This movement is directly linked to a wiper mechanism that adjusts the resistance within the variable resistor.

● Adjusting the Resistance: The variable resistor consists of a resistive element (often a conductive track) and a wiper. As the float moves, it causes the wiper to slide along the resistive track, changing the resistance. When the gas level is high, the resistance is low, and when the gas level decreases, the resistance increases.

● Sending the Signal: The change in resistance is detected by the gas gauge's electronic system, which is calibrated to interpret the resistance values. The electrical signal generated by the variable resistor is then processed by the gauge, which translates the resistance into a readable display, showing the user the amount of LP gas remaining in the tank.

● Providing Accurate Measurement: Since the resistance changes smoothly in response to the float's position, the variable resistor enables accurate and continuous tracking of the gas level. This results in precise readings that are essential for monitoring the gas tank and ensuring efficient usage.

In this way, the ceramic variable resistor acts as a sensor, translating the mechanical movement of the float into an electrical signal that provides a real-time measurement of the LP gas level in the tank. This mechanism is reliable, durable, and widely used in both residential and industrial LP gas monitoring systems.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors