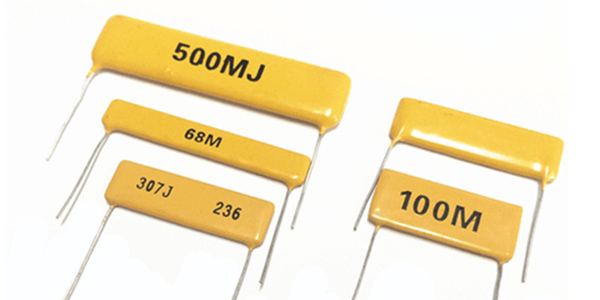

High Voltage Ceramic Resistors

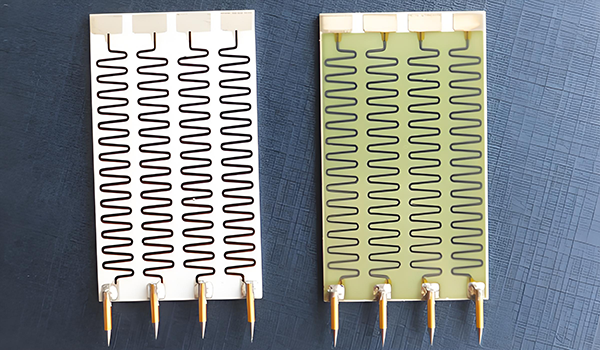

High Voltage Ceramic Resistors, also called Ceramic High Voltage Resistors, are electronic components designed to withstand high voltage levels, utilizing thick film technology where a conductive material slurry is printed onto a ceramic substrate to create a high-resistance layer that can be customized based on customer requirements, such as size, target value, and power, for both specialized and general-purpose production, ensuring reliable performance even in demanding environments, with their ceramic structure enabling them to effectively handle and operate in circuits requiring high voltage resistance.

High Voltage Ceramic Resistors made with thick film technology exhibit exceptional resistance to environmental stressors such as moisture, humidity, and temperature fluctuations. This design ensures precise control of voltage and current, guaranteeing stable and long-lasting performance. The ceramic substrate acts as an insulator, offering high breakdown voltage while maintaining a compact size. These resistors are also known for their excellent temperature stability, which allows them to function reliably in extreme conditions without compromising performance.

Ceramic High Voltage Resistors are widely used in various industries, including consumer electronics, automotive, and medical equipment. In these applications, Ceramic High Voltage Resistors perform crucial functions like voltage division, signal conditioning, and current limiting. Their reliability and precision make them ideal for circuits that demand high-performance components. Additionally, their compact size and ability to withstand high voltage make them suitable for use in space-constrained electronic systems, where power efficiency is crucial. These ceramic resistors also contribute to the safety and reliability of critical electrical systems in automotive and medical devices.

Features of High Voltage Ceramic Resistors :

● High Voltage Handling: Designed to withstand high voltage levels without compromising safety or performance, HVCRs effectively manage high power loads.

● Temperature Stability: Ceramic materials offer excellent temperature stability, ensuring that the resistor's performance remains consistent under varying thermal conditions.

● Low Inductance: The construction of ceramic high voltage resistors results in minimal inductance, which is beneficial for high-frequency applications.

● Chemical Inertness: Ceramics are chemically inert, providing resistance to corrosive environments and ensuring a long service life.

● Excellent Environmental Resistance: These resistors exhibit exceptional resistance to moisture, humidity, and corrosive substances, ensuring long-term reliability in harsh conditions.

● Compact and Lightweight Design: Featuring a compact and lightweight construction, HVCRs are easily integrated into various electronic devices and systems.

● Low Noise and Distortion: HVCRs deliver minimal noise and distortion levels, ideal for applications requiring high signal integrity.

Classification of High Voltage Ceramic Resistors :

High Voltage Ceramic Resistors can be classified based on their structure, power rating, and application requirements:

● Structure: High Voltage Ceramic Resistors can be categorized as through-hole, surface-mount devices and chip resistors, with the latter being more prevalent in modern electronics due to their ease of assembly and compact design.

● Power Rating: Resistors are classified according to their maximum power dissipation, ranging from low power (a few watts) to high power (several tens of watts).

● Application: Specific types are designed for high voltage power supply applications, while others are tailored for use in pulsed power systems or as load resistors in various circuits.

Advantages of High Voltage Ceramic Resistors :

● High Voltage Ratings: High Voltage Ceramic Resistors are designed to handle elevated voltage levels, making them ideal for applications requiring voltage division or power distribution.

● Wide Range of Resistance Values: Available in a diverse range of resistance values, from low ohms to high megaohms, these resistors cater to a variety of application requirements.

● Compact Size: Despite their high power ratings, High Voltage Ceramic Resistors maintain a compact form factor, making them well-suited for space-constrained applications.

● Stability: Utilizing advanced ceramic resistor technology, these components exhibit exceptional long-term stability, minimizing resistance drift caused by environmental factors such as temperature fluctuations.

● High Precision: With low tolerance levels, High Voltage Ceramic Resistors offer precise resistance values, enabling accurate control of voltage and current in electronic circuits.

● Power Handling Capability: Engineered to withstand high power loads, these resistors deliver reliable performance without sacrificing efficiency. Their robust thermal conductivity ensures effective heat dissipation, enhancing overall reliability.

Applications of Ceramic High Voltage Resistors :

Ceramic High Voltage Resistors are specialized components that are valued for their ability to handle high voltages with precision and reliability. They are utilized in a variety of applications across different industries due to their unique properties, such as high dielectric strength, stability, low temperature coefficient, and mechanical robustness . Some of the key applications of high voltage ceramic resistors include:

● Power Electronics: Ceramic High Voltage Resistors are used in power supplies, inverters, and converters where stable voltage regulation and current limiting are crucial.

● Snubbers and Inrush Limiting: Due to their pulsed duty capabilities and low inductance, ceramic resistors are ideal for applications requiring high peak power or high voltage with inrush limiting.

● Medical Equipment: High voltage ceramic resistors are used in the power supplies of medical devices to ensure safe and accurate operation.

● Industrial Automation: They are employed in motor controls, robotics, and industrial machinery where components must operate reliably under tough conditions.

● Telecommunications: These Ceramic High Voltage Resistors are found in communication equipment, antennas, and transmission systems that demand stable performance in changing environments.

● High Voltage Power Supplies: Ceramic High Voltage Resistors are used in high voltage power supplies for their ability to withstand and regulate high voltages.

● R-C Snubber Circuits: In these circuits, Ceramic High Voltage Resistors help to reduce voltage surges or spikes.

● Capacitor Charge/Discharge: They are used in applications that require the controlled charging and discharging of capacitors, such as in pulse forming and crowbar circuits.

● Laser/Imaging Equipment: Ceramic High Voltage Resistors are also used in laser and imaging equipment due to their precision and stability.

● RF Combiners: In radio frequency applications, they help in combining signals with minimal distortion.

● Oscillatory De-Qing Circuits: They are used to prevent the oscillation of circuits by de-Qing them.

Manufacturing of High Voltage Ceramic Resistors :

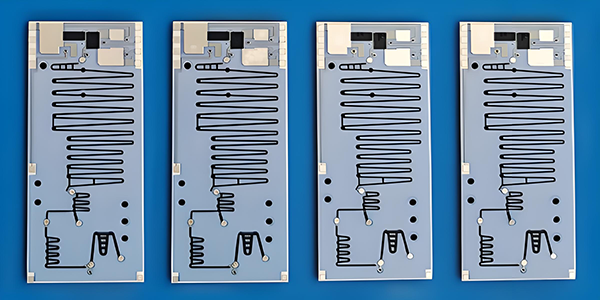

High Voltage Ceramic Resistors are critical components in various electrical and electronic systems, particularly those requiring high voltage insulation and precise resistance values. The manufacturing process of these resistors using thick-film technology is a sophisticated and precise method that involves several key steps:

● Substrate Preparation: The process begins with the selection of an appropriate ceramic substrate, which is typically made from materials like Alumina (Al2O3) due to its excellent electrical insulation properties and high-temperature stability.

● Paste Formulation: A thick-film paste is formulated, which consists of a mixture of conductive materials, such as ruthenium dioxide or other metal oxides, with a glass frit and an organic vehicle. The paste is designed to provide the desired resistivity and stability under high voltage conditions.

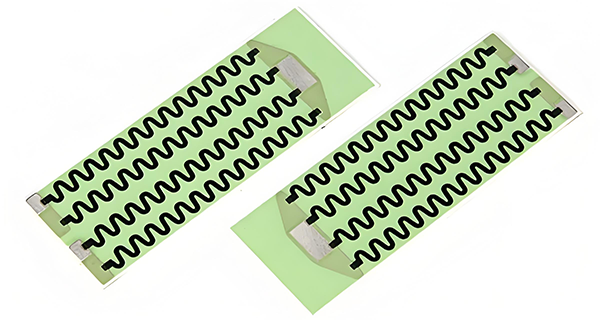

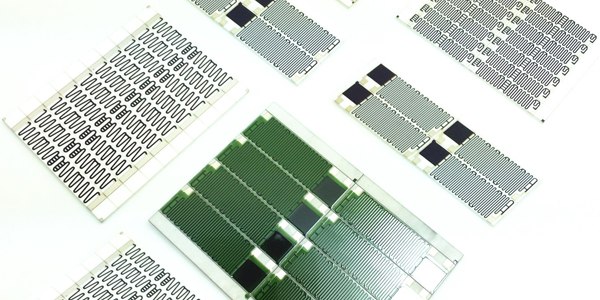

● Screen Printing: The thick-film paste is screen printed onto the ceramic substrate in a pattern that defines the resistor's geometry. This step requires precision to ensure the correct dimensions and resistance values.

● Drying and Firing: After printing, the substrate is dried to remove the organic vehicle and then fired at high temperatures. The firing process hardens the paste into a durable and conductive layer, and the glass frit aids in adhering the layer to the substrate.

● Laser Trimming: To achieve the precise resistance value, the resistors may undergo laser trimming. This process carefully removes a small portion of the resistive layer, adjusting the resistance to meet the required specifications.

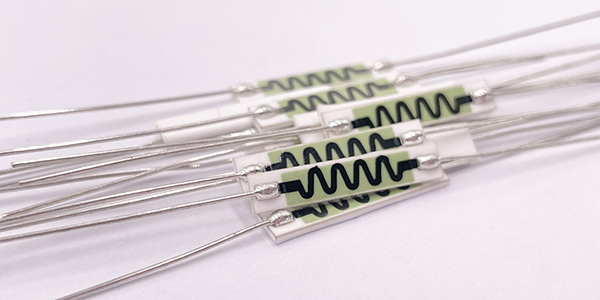

● Terminal Attachment: Terminals are attached to the resistor to facilitate connection to the external circuit. This can be done through methods like soldering or using conductive adhesives.

● Testing and Quality Control: Each resistor is tested for its resistance value, stability, and ability to withstand high voltage. Quality control measures ensure that the products meet industry standards and customer requirements.

● Packaging: Finally, the resistors are packaged for protection during transport and storage, ready for use in various high voltage applications.

Specifications of Ceramic High Voltage Resistors :

● Resistance Value Range (Ω): From 10K Ω to 10 GΩ.

● Tolerance: Standard range is ±1% to ±10%, and can be restricted to ±0.1% to ±0.5% upon special request.

● Temperature Coefficient: Typically 50 ppm/°C for resistances ≥ 10 Ω (referenced at 25°C, ΔR taken from -15°C to +85°C), and can be 25 ppm/°C upon special request.

● Operating Temperature: Up to a maximum of +275°C.

● Dielectric Strength: A minimum of 1,000 V DC.

● Insulation Resistance: A minimum of 10 GΩ at 1,000 volts direct current.

● Overload Capability: Capable of withstanding 5 times the rated power, with the applied voltage not exceeding 1.5 times the maximum continuous working voltage, for a duration of 5 seconds.

● Load Life: 1,000 hours at rated power, with a maximum change in resistance (ΔR) of 0.5% or a maximum of 0.5 Ω.

● Encapsulation: Standard coating is silicone conformal, and other coatings such as 2x polyimide coating can be used for special applications like oil and potted applications.

● Rated Energy: Different models of resistors may have different rated energies.

● Operating Temperature Range: Some high-energy resistors have an operating temperature range of -55°C to +230°C.

● Size and Shape: Ceramic High Voltage Resistors can come in various sizes and shapes, such as disc series, with solid and hollow options available, and can be freely combined.

Why Deed to Customize High Voltage Ceramic Resistors ?

● Unique Voltage Requirements: High voltage applications may demand resistors that can withstand voltages beyond the standard limits, necessitating customization for safety and reliability.

● Precision Tolerances: Custom High Voltage Ceramic Resistors can be made to very tight tolerances, ensuring the accuracy needed for sensitive or critical high voltage measurements and operations.

● Power Ratings: High voltage circuits often require resistors with specific power dissipation capabilities. Customization allows for designing resistors that can handle the required power without overheating or failing.

● Environmental Adaptability: Electronic devices used in challenging environments may need resistors that can operate reliably under extreme temperatures, humidity, or other conditions. Custom Thick Film High Voltage Resistor can be engineered for such environments.

● Miniaturization: As technology advances towards smaller devices, there's a need for high voltage resistors that can fit into compact spaces without losing their ability to perform under high voltage conditions.

● Noise Characteristics: In high voltage applications where noise can interfere with performance, custom resistors can be designed to minimize electrical noise and maintain signal integrity.

● Regulatory Compliance: Certain industries have strict regulations regarding the use of electronic components. Custom high voltage resistors can be tailored to meet these regulatory standards.

● Supply Chain Control: Customizing High Voltage Ceramic Resistors ensures a consistent supply, preventing disruptions due to the obsolescence or unavailability of standard components.

● Cost-Benefit Analysis: While the upfront cost of customization may be higher, the long-term benefits in terms of performance, reliability, and reduced maintenance can make it a more cost-effective solution.

● Technical Collaboration: Customization involves close collaboration with manufacturers, which can lead to innovative solutions that precisely match the application's needs.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors