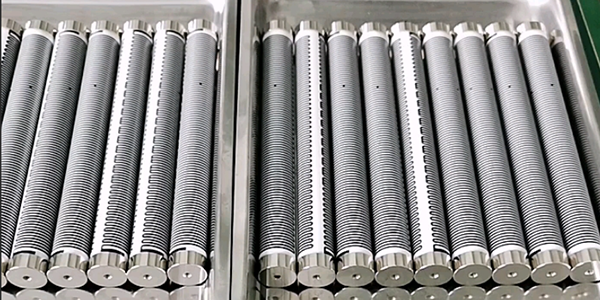

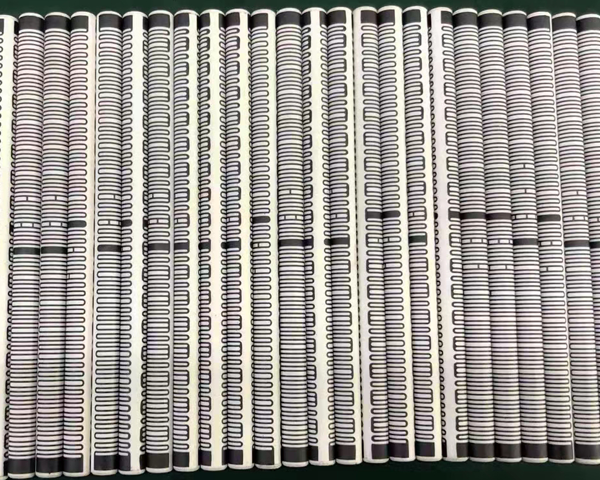

Thick Film Tubular Resistors

Thick Film Tubular Resistors, also called Thick Film Cylindrical Resistors, are resistor components manufactured using thick film technology on ceramic or glass substrates, with a thick film of resistive material typically composed of metal oxides, metals, or semiconductor compounds printed onto the surface of a tubular or cylindrical substrate and fused through a high-temperature sintering process, resulting in a highly stable resistive material that is known for its precision, low noise, and excellent mechanical strength, making them ideal for circuits requiring high reliability.

Thick Film Tubular Resistors offer several key advantages. They provide stable resistance values and can handle high voltage and large power loads. The cylindrical design ensures effective heat dissipation, allowing the resistor to maintain long-term reliability under high-power applications. Additionally, these resistors can operate in a wide temperature range, often surviving environments up to several hundred degrees Celsius. The precision of the thick film process allows for accurate resistance control, making them suitable for applications requiring high accuracy and long-term stability.

Thick Film Cylindrical Resistors are widely used across various industries, particularly in high-voltage circuits and high-power electronic devices. In power systems, they are used for voltage control and current limiting, protecting circuits from voltage spikes. In industrial automation and automotive electronics, they are employed in critical control systems, ensuring precise regulation and stability of voltage and current. Furthermore, Thick Film Cylindrical Resistors are commonly found in communication equipment and military electronics, particularly in applications that require high stability, high-temperature resistance, and electromagnetic interference protection. Their high-power handling capabilities and excellent heat dissipation make them essential in these systems for protection and precise control.

Features of Thick Film Tubular Resistors :

● High Stability and Precision: Thick Film Tubular Resistors offer exceptional stability and precision in resistance values, ensuring reliable performance over extended periods. This makes them ideal for applications that require consistent and accurate resistance, even under varying environmental conditions.

● Excellent Heat Dissipation: The cylindrical shape of these resistors enhances heat dissipation, allowing them to handle high power loads effectively. Their design helps prevent overheating, ensuring that the resistor operates within safe thermal limits even in demanding applications.

● Durability and Mechanical Strength: Constructed from ceramic or glass substrates, tubular thick film resistors are known for their robust mechanical strength. They are resistant to mechanical stress, vibrations, and physical impact, making them suitable for harsh environments.

● Wide Temperature Range: Thick Film Tubular Resistors can operate across a broad temperature range, typically from -55°C to +250°C or higher, making them suitable for applications in extreme temperature conditions.

● Low Noise and High Accuracy: Thick film technology ensures low noise characteristics, which is essential for precision circuits and signal processing. This allows them to maintain high accuracy even in sensitive electronic devices.

● High Power Handling: Thick Film Tubular Resistors can handle high power levels without compromising their performance. This makes them a preferred choice for power-sensitive applications, including industrial equipment, automotive electronics, and high-voltage systems.

● Electromagnetic Interference Resistance: The design and materials used in these resistors make them highly resistant to electromagnetic interference (EMI), which is crucial for maintaining signal integrity in communication and military electronics.

Advantages of Thick Film Cylindrical Resistors :

● Enhanced Heat Dissipation: The cylindrical design allows for efficient heat distribution and cooling, which is essential for high-power applications, ensuring the resistor operates at optimal performance without overheating.

● Structural Integrity: The tubular shape provides superior mechanical strength, safeguarding the resistive element from physical damage caused by vibrations, shock, or mechanical stress, which is especially important in demanding environments.

● Precision and Consistency: Thanks to the thick film technology, these resistors offer highly precise and consistent resistance values, ensuring stable and reliable performance over time, even under fluctuating conditions.

● Wide Operating Temperature Range: Thick Film Cylindrical Resistors are designed to function effectively across a wide temperature range, typically from -55°C to +250°C or higher, making them suitable for applications in diverse environments, from industrial settings to automotive electronics.

● Longevity and Durability: Their robust design and the high-quality materials used ensure that these resistors have a long lifespan, with minimal degradation in performance, even under harsh conditions, reducing the need for frequent replacements.

● Low Noise Performance: The use of high-quality materials in the manufacturing process results in low noise characteristics, making these resistors ideal for sensitive electronic circuits where minimal interference is required.

● High Power Handling Capability: Thick Film Cylindrical Resistors are engineered to handle higher power loads effectively, making them perfect for power-sensitive applications in industrial, automotive, and high-voltage systems, where heat management and power dissipation are critical.

Applications of Thick Film Cylindrical Resistors :

● Power Electronics: Thick film cylindrical resistors are widely used in power electronics, where high power handling and efficient heat dissipation are essential. They are commonly found in power supplies, voltage regulation circuits, and inverters, ensuring stable and reliable operation in high-power applications.

● Industrial Equipment: These resistors are used in various industrial applications, such as machinery control systems, motor drives, and automation equipment, where they help regulate current and protect circuits from voltage spikes, ensuring smooth and efficient operation.

● Automotive Electronics: In automotive systems, thick film cylindrical resistors are employed in engine control units (ECUs), lighting systems, power steering, and other critical vehicle electronics, where their durability, precision, and ability to function in extreme temperatures are highly valued.

● Telecommunications: They are crucial in telecommunications equipment, including signal processing circuits, power amplifiers, and transmission lines, where low noise and consistent performance are required to ensure clear and reliable communication.

● Military and Aerospace: Due to their high durability and resistance to extreme environmental conditions, thick film cylindrical resistors are widely used in military and aerospace applications, including radar systems, communication devices, and avionics, where reliability and performance in harsh environments are critical.

● Medical Equipment: Thick film cylindrical resistors are also used in medical devices such as diagnostic equipment, imaging systems, and patient monitoring devices, where precision and long-term reliability are crucial for accurate readings and patient safety.

● Consumer Electronics: In consumer electronics, such as power amplifiers, audio equipment, and home appliances, these resistors are used to ensure stable operation and prevent overheating, helping to maintain the longevity and functionality of the devices.

● Renewable Energy Systems: In renewable energy applications, like solar inverters and wind turbine control systems, thick film cylindrical resistors are used to manage power flow, voltage regulation, and current limiting, ensuring the efficiency and longevity of the systems.

● Test and Measurement Instruments: Thick film cylindrical resistors are utilized in test and measurement devices, such as oscilloscopes, spectrum analyzers, and power meters, where high precision and accuracy are essential for obtaining reliable readings.

Why Deed to Customize Thick Film Tubular Resistors ?

● Exacting Specifications: Custom Thick Film Tubular Resistors can be tailored to meet precise resistance values that are not available in standard offerings, which is critical for applications requiring high accuracy.

● Environmental Resilience: For devices operating in harsh conditions, such as extreme temperatures or corrosive environments, custom tubular resistors can be made with materials that provide the necessary durability and longevity.

● Miniaturization: As technology trends towards smaller form factors, custom resistors can be designed to fit into compact spaces without compromising on performance.

● Power Handling: Custom Thick Film Tubular Resistors allows for the creation of resistors that can handle specific power levels, which is essential for high-power applications.

● Noise Reduction: In sensitive electronic systems, custom resistors can be optimized to reduce electrical noise, ensuring clearer signal transmission and measurement.

● Regulatory Compliance: Custom Thick Film Tubular Resistors can be designed to meet industry-specific regulatory requirements, ensuring that the end product is compliant with legal standards.

● Supply Chain Assurance: By customizing, manufacturers can ensure a stable supply of components that are not subject to the availability of standard products, which can become obsolete.

● Cost-Effectiveness: While the initial cost may be higher, the long-term reliability and performance of custom resistors can lead to cost savings by reducing the need for maintenance and replacement.

● Technical Collaboration: Working with a manufacturer to customize a product allows for a more collaborative and innovative approach to solving specific design challenges.

● Integration with Complex Systems: Custom Thick Film Tubular Resistors can be designed to integrate more effectively with other components in a complex electronic system, enhancing overall performance and reliability.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors