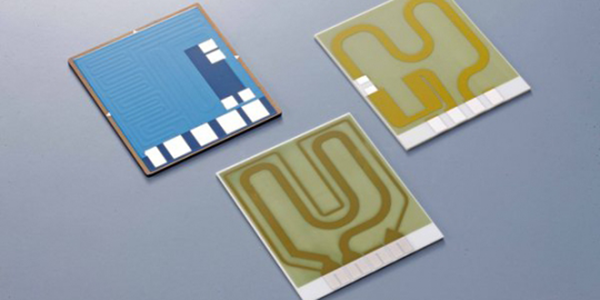

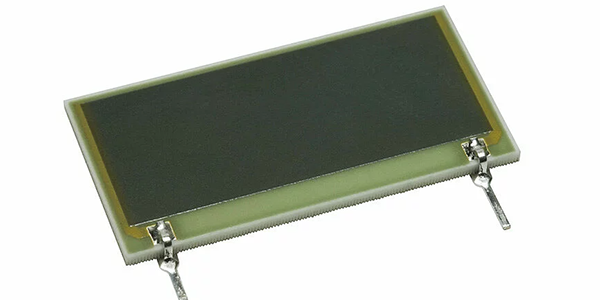

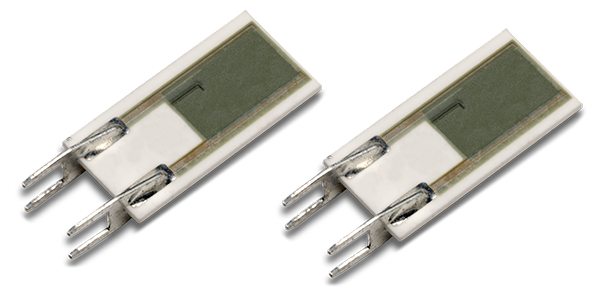

Thick Film Planar Resistors

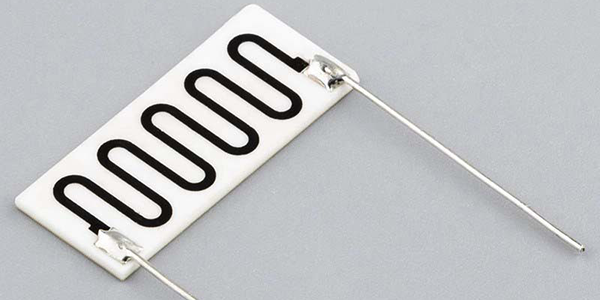

Thick Film Planar Resistors, also called Thick Film Flat Resistors, are electronic components manufactured using thick film technology with a flat, planar structure, where the resistor elements are applied onto a ceramic substrate as a resistive paste, typically composed of ruthenium oxide and glass binder, using techniques like screen printing or sputtering, followed by high-temperature firing to bond the material securely, resulting in resistors with precise resistance values, excellent stability, and minimal variation over time.

Thick Film Planar Resistors are known for their high precision and stability, making them ideal for a wide range of electronic applications. Their flat, compact design ensures space efficiency while offering durability, heat resistance, and reliability. Made from metal oxides or metal-semiconductor compounds, these resistors perform reliably under varying temperatures and environmental stresses. They can also handle significant power dissipation with minimal noise interference, making them perfect for complex circuit designs and precise signal processing.

Thick Film Flat Resistors are widely used in different industries due to their robustness and compact size. In telecommunications, they are critical in filters, signal processing circuits, and power supplies, where stability and high power handling are essential. In automotive electronics, they are found in engine control units and safety systems, withstanding vibrations and extreme temperatures. Medical equipment uses these resistors for diagnostic and monitoring devices requiring long-term reliability. In consumer electronics, they are employed for signal conditioning, noise filtering, and power regulation in devices like smartphones, TVs, and audio equipment, while their precision also benefits industrial control systems, computing, and military applications.

Manufacturing of Thick Film Planar Resistors :

● Substrate Preparation: The process typically starts with a substrate, which is often made of a material like alumina (aluminum oxide) due to its high hardness and thermal stability. The substrate may be laser-cut into the desired shape and have holes drilled for mounting purposes.

● Paste Preparation: A thick film paste is prepared, which is a mixture of ceramic or metal powders with a glass or polymer binder. This paste, also known as ink, is formulated to have the desired electrical resistivity.

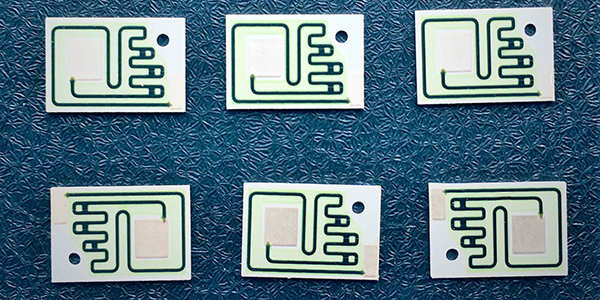

● Screen Printing: The prepared paste is then screen printed onto the substrate in a pattern that determines the resistance value. This step involves transferring the paste through a mesh screen with a patterned stencil onto the substrate.

● Drying: After printing, the ink layer is dried to remove the solvents and partially sinter the material, which helps it adhere to the substrate.

● Firing: The substrate with the printed pattern is fired at high temperatures, typically around 850°C. This step burns off the organic components of the paste and fuses the metal particles to form a solid, conductive film.

● Laser Trimming: Once the resistor has been fired, the resistance value may be trimmed to achieve the desired accuracy. This can be done mechanically or, more precisely, with a laser.

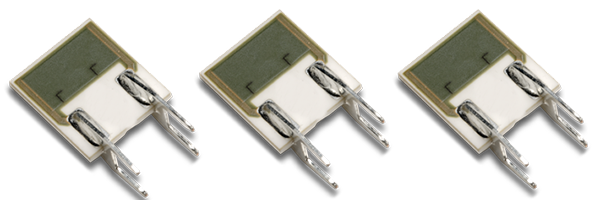

● Environmental Coating: To protect the resistor from environmental factors such as moisture and chemicals, a coating is applied over the resistor element. This coating is also designed to enhance the insulation resistance and dielectric strength of the device.

Applications of Thick Film Planar Resistors :

● High-Reliability Circuits: Thick Film Planar Resistors are critical in aerospace and medical applications, where consistent performance and long-term stability are essential for ensuring safety and functionality in high-risk environments.

● Automotive Electronics: In automotive systems, they are incorporated into engine control units (ECUs) and safety mechanisms. Their ability to withstand extreme temperature fluctuations, vibrations, and environmental stressors ensures reliable operation, making them vital in maintaining vehicle performance and safety.

● Telecommunications: Thick Film Planar Resistors are integral to communication devices requiring accurate signal processing and minimal electromagnetic interference. Their stability and low-noise characteristics are crucial for maintaining the integrity of signal transmission in modern communication networks.

● Military and Defense: In military systems, where equipment must endure harsh conditions such as high temperatures, moisture, and physical shocks, Thick Film Planar Resistors provide unmatched durability and performance, ensuring mission-critical systems function reliably in demanding environments.

● Consumer Electronics: Found in high-end audio systems, precision measurement instruments, and other consumer electronics, these resistors ensure optimal signal conditioning and power regulation, contributing to superior product performance and longevity.

● Industrial Control Systems: In automation and control systems, these resistors are used to maintain consistent resistance in circuits that regulate machinery, robotics, and manufacturing processes. Their ability to handle significant power dissipation without compromising accuracy is crucial for ensuring system efficiency and safety in industrial environments.

Advantages of Thick Film Flat Resistors :

● Uniformity: The flat design ensures a uniform distribution of current across the resistor, reducing the risk of hot spots and improving thermal performance.

● Integration: Thick Film Flat Resistors can be integrated with other thick film components like capacitors and inductors on the same substrate, leading to miniaturized and cost-effective solutions.

● Surface Mount Technology (SMT): Thick Film Flat Resistors are designed for surface mount applications, which allow for automated placement on printed circuit boards and contribute to the miniaturization of electronic devices.

● Customization: Thick film technology allows for a high degree of customization in terms of resistance values, tolerances, and physical dimensions, making it suitable for a wide range of applications with specific requirements.

Why Deed to Customize Thick Film Planar Resistors ?

● Custom Thick Film Planar Resistors are a strategic decision that caters to the unique demands of specialized electronic applications. Here are several reasons why one might deem it necessary to customize thick film planar resistors:

● Specific Tolerance and Stability: Standard resistors may not provide the exact tolerance or temperature coefficient of resistance required for high-precision applications. Customization allows for the creation of resistors with tailored tolerances and stability characteristics to ensure accurate and consistent performance.

● Unique Resistance Values: Off-the-shelf resistors come in standard values, which might not suffice for certain designs. Custom thick film planar resistors can be manufactured to achieve non-standard resistance values that meet the exact specifications of the application.

● Environmental Adaptability: Electronic devices used in extreme environments, such as those exposed to high temperatures, corrosive chemicals, or mechanical stress, require resistors that can withstand these conditions. Customization enables the selection of materials and protective coatings that offer the necessary resilience.

● Miniaturization Needs: As electronic devices become smaller, the components within them must also scale down without losing functionality. Custom thick film planar resistors can be designed to fit into compact spaces while maintaining their performance.

● Power Dissipation Requirements: High-power applications may necessitate resistors capable of dissipating more heat than standard resistors can handle. Customization allows for the design of resistors with enhanced power dissipation capabilities.

● Noise Characteristics: Applications that are sensitive to electrical noise, such as in measurement and communication systems, may require resistors with specific noise characteristics. Custom thick film planar resistors can be optimized to minimize noise interference.

● Longevity and Supply Chain Management: Custom Thick Film Planar Resistors can be manufactured with a long-term availability plan, ensuring that as technology evolves, the specific components needed remain accessible and are not subject to sudden obsolescence.

● Regulatory and Compliance Standards: Industries such as medical, aerospace, and automotive have strict compliance standards. Custom resistors can be designed to meet these standards, ensuring the legality and safety of the end products.

● Cost-Benefit Analysis: While the upfront cost of custom resistors may be higher, the long-term benefits in terms of performance, reliability, and the avoidance of costly redesigns or replacements can make customization a cost-effective choice.

● Technical Collaboration and Innovation: Engaging in a customization process often involves close collaboration with the manufacturer, leading to a deeper understanding of the application's needs and potentially driving innovation in resistor design.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors