Humidity Sensitive Ceramic Resistors

Humidity Sensitive Ceramic Resistors, also called Ceramic Humidity Sensitive Resistors, are electronic components designed to measure environmental humidity and utilize the property of specific ceramic materials to change their electrical resistance in response to varying humidity levels, typically made from porous ceramic materials, such as metal oxide semiconductors like titanium dioxide (TiO2) and aluminum oxide (Al2O3), which exhibit resistance changes when exposed to water vapor, with the working principle relying on the change in resistance as ambient humidity fluctuates.

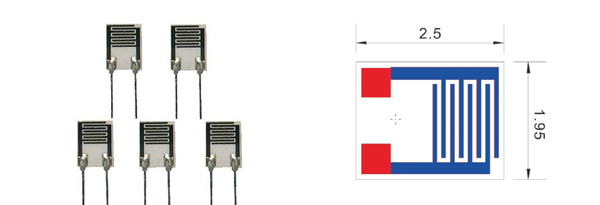

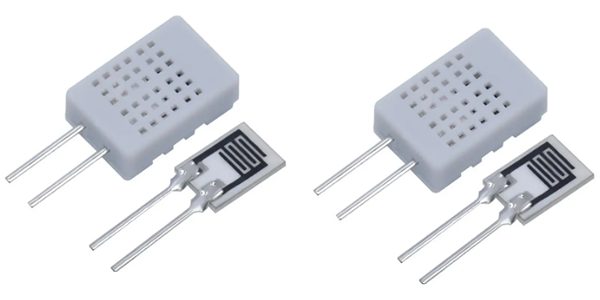

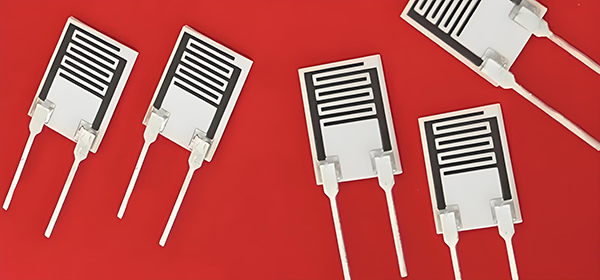

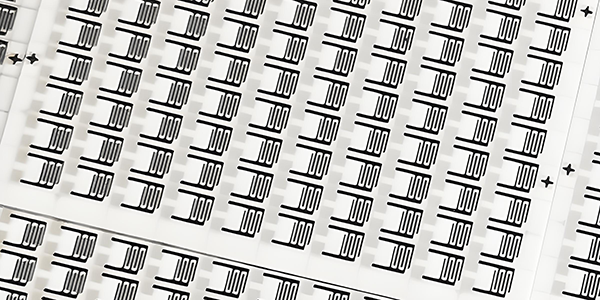

Humidity Sensitive Ceramic Resistors are renowned for their high precision, reliability, and cost-efficiency. Their key features include a wide humidity detection range, fast response time, durability, and the ability to function stably in high-humidity environments. Compared to traditional humidity sensors, these resistors offer lower production costs and simpler manufacturing processes. They are typically made by screen-printing ceramic paste onto a substrate, forming a thick film structure to create the sensing element. This method not only enhances production efficiency but also allows for mass production of the sensors.

Ceramic Humidity Sensitive Resistors find widespread use across various industries, including home appliances, meteorological equipment, automation control systems, and industrial monitoring. In home appliances, they are commonly used in air conditioning units and dehumidifiers to maintain optimal humidity levels. In meteorological instruments, these resistors accurately measure air humidity to assist with weather forecasting and climate analysis. Additionally, in industrial applications, these sensors monitor changes in humidity within production environments, preventing damage to equipment caused by extreme humidity levels. With their stability and efficiency, Humidity Sensitive Ceramic Resistors have become essential components in humidity monitoring systems.

Manufacturing of Humidity Sensitive Ceramic Resistors :

Humidity Sensitive Ceramic Resistors are primarily produced through thick-film technology, a process that includes several carefully executed stages.

● Material Preparation: Ceramic materials, typically metal oxides such as titanium dioxide (TiO2) or aluminum oxide (Al2O3), are processed into a fine powder to ensure optimal consistency and performance for the sensor.

● Screen Printing: The ceramic paste, prepared from the powdered material, is precisely screen-printed onto a substrate, often made of ceramic or glass. This step defines the specific pattern that forms the sensing element of the resistor.

● Firing: The printed substrate undergoes high-temperature firing in a controlled kiln to burn off the organic binders and sinter the ceramic particles. This process ensures the formation of a strong, durable, and porous ceramic layer that is capable of responding to humidity changes.

● Electrode Attachment: Metal electrodes, typically made from silver, gold, or other conductive materials, are applied to the ceramic layer to enable the measurement of changes in electrical resistance as the humidity levels vary.

● Dicing and Packaging: After the electrodes are attached, the sensors are precision-cut into individual units using a dicing saw. The final step involves packaging the sensors into protective casings that safeguard the components during transportation and installation.

Features of Humidity Sensitive Ceramic Resistors :

Humidity Sensitive Ceramic Resistors are characterized by several key features that make them reliable and efficient in measuring ambient humidity levels:

● High Sensitivity: These resistors exhibit excellent sensitivity to changes in humidity, making them highly accurate in detecting variations in environmental moisture levels.

● Wide Humidity Detection Range: Humidity Sensitive Ceramic Resistors can operate effectively across a broad range of humidity levels, ensuring they can be used in various environments, from extremely dry to highly humid conditions.

● Fast Response Time: These resistors have a rapid response to changes in humidity, allowing for real-time monitoring of environmental conditions.

● Durability and Stability: Made from robust ceramic materials, these resistors are durable and stable even in harsh environmental conditions, such as high humidity or temperature fluctuations.

● Low Power Consumption: Humidity Sensitive Ceramic Resistors consume minimal power, making them suitable for energy-efficient applications, including battery-operated devices.

● Cost-Effective: Compared to other humidity sensors, these resistors are relatively low-cost, offering an affordable solution without compromising on performance or reliability.

● Simple Integration: With their straightforward design, Humidity Sensitive Ceramic Resistors are easy to integrate into a wide variety of electronic systems and devices.

Product Types of Humidity Sensitive Ceramic Resistors :

Humidity Sensitive Ceramic Resistors come in various types, each with unique characteristics that suit different applications.

● Ceramic Material-Based Sensors: Humidity Sensitive Ceramic Resistors utilize ceramic materials for their construction, offering advantages such as better thermal stability and resistance to chemicals compared to polymer-based sensors .

● Metal Dichalcogenides (MDCs)-Based Sensors: Humidity Sensitive Ceramic Resistors based on materials like SnS2, which are known for their extraordinary properties in nano-electromechanical devices, can be used for humidity sensing. They can be fabricated using techniques such as chemical vapor deposition (CVD), hydrothermal and solvothermal synthesis, and sputtering .

● MnZn Ferrite-Based Sensors: A specific type of ceramic sensor that uses MnZn ferrite, which has been developed and manufactured using screen-printing technology. These sensors have shown good stability, low hysteresis, and fast response time .

● Self-Powered Sensors: Some thick film humidity sensors are designed to be self-powered, meaning they do not require an external power supply for operation. They utilize internal electric fields for charge carrier separation, which is particularly useful in devices involving multiple sensors .

● Planar Humidity Sensors: Humidity Sensitive Ceramic Resistors are based on a specific microstructure that allows for reproducible production with defined porosity and grain structure, which is crucial for their performance .

● Room Temperature Sensors: Some Humidity Sensitive Ceramic Resistors are designed to operate effectively at room temperature, which simplifies their integration into various systems and reduces the need for additional temperature control mechanisms .

Applications of Ceramic Humidity Sensitive Resistors :

Ceramic Humidity Sensitive Resistors have a wide range of applications across various industries due to their ability to detect and measure changes in humidity levels. Here are some of the key applications:

● Industrial Processes: Ceramic Humidity Sensitive Resistors are used to monitor and control humidity in manufacturing processes, such as in the production of foods, pharmaceuticals, and chemicals, where precise environmental conditions are critical .

● Domestic Appliances: Humidity sensors can be found in household appliances like air conditioners and dehumidifiers to maintain optimal comfort levels and prevent mold growth .

● Automobiles: Ceramic Humidity Sensitive Resistors are used in automotive applications for controlling the internal environment and preventing the formation of condensation on windows .

● Medical Services: In healthcare, humidity sensors can be crucial for maintaining sterile conditions in operating rooms and for preserving the quality of moisture-sensitive medical supplies .

● Environmental Monitoring: Ceramic Humidity Sensitive Resistors are used for tracking weather patterns and environmental conditions, which is essential for agriculture and climate research .

● Wearable Technology: With the rise of smart wearables, HSRs can be integrated into devices for personal health monitoring, such as detecting sweat or skin moisture .

● Biomedical Applications: Humidity sensors can be used in medical devices for non-contact sensing of bodily fluids or for monitoring the humidity in patient care environments .

● Consumer Electronics: Ceramic Humidity Sensitive Resistors can be used in electronic devices to ensure that the internal components are protected from moisture damage, prolonging the life of the product .

● Smart Packaging: In the food industry, HSRs can be integrated into packaging to monitor the freshness of products and ensure optimal storage conditions .

● Breath Monitoring: Self-powered, ultrasensitive humidity sensors can be used for breath analysis in medical diagnostics, detecting signs of various respiratory conditions .

Advantages of Ceramic Humidity Sensitive Resistors :

Ceramic Humidity Sensitive Resistors offer several advantages that make them suitable for a variety of applications:

● High Sensitivity: Ceramic Humidity Sensitive Resistors can exhibit high sensitivity to changes in humidity levels, which is crucial for accurate monitoring and control in various environments.

● Simple Fabrication Process: The thick film process involves screen printing and sintering, which is relatively simple and allows for easy integration into existing manufacturing processes.

● Good Stability and Reliability: When manufactured correctly, thick film resistors can offer long-term stability and reliability, making them suitable for long-lasting applications.

● Wide Resistance Value Range: Thick film technology can produce a broad range of resistance values, providing flexibility in design and application.

● High Power Handling Capability: Compared to thin film resistors, thick film resistors can handle higher power levels, which is beneficial for applications requiring robust performance under load.

● Customization: The thick film process allows for the customization of the resistor's geometry and composition to meet specific application requirements.

● Resistance to Environmental Factors: Thick film resistors are known for their ability to resist various environmental factors such as moisture, which is particularly important for humidity sensing applications.

● Automated Production: The thick film process is well-suited for automation, which can improve production efficiency and reduce the potential for human error.

● Versatility in Applications: As evidenced by their use in sensors, circuit boards, displays, and memory devices, thick film resistors have a wide range of applications due to their versatility and performance characteristics.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors