High Value Ceramic Resistors

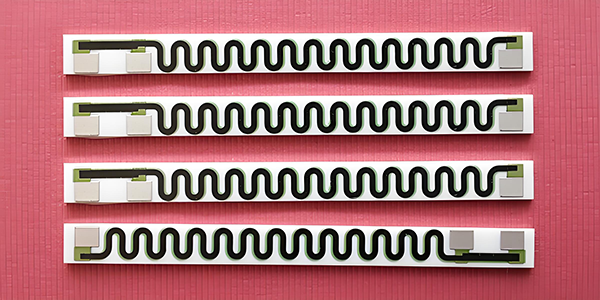

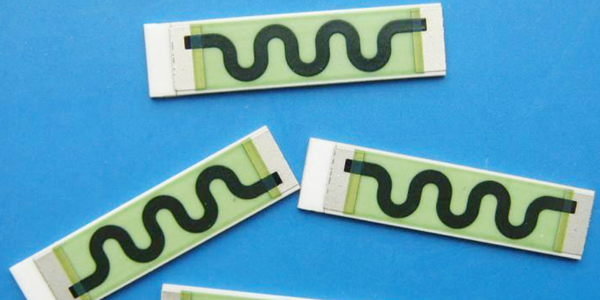

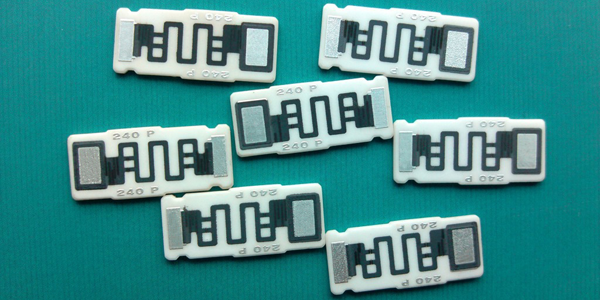

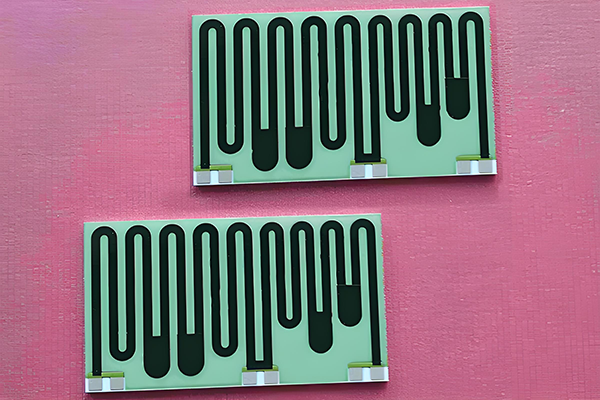

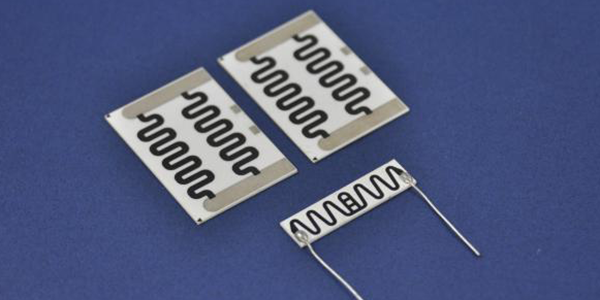

High Value Ceramic Resistors, also called Ceramic High Value Resistors, are high-power resistors made using thick-film technology combined with ceramic substrates, designed to provide high resistance values while maintaining the stability and reliability of electronic circuits, with the manufacturing process involving the application of a conductive and resistive paste onto a ceramic substrate through screen printing, followed by curing, high-temperature sintering, and laser trimming to ensure precision, and the final product is customized to meet the specific requirements of customers, including dimensions, target resistance values, and power ratings, resulting in either specialized or general-purpose resistive components.

High Value Ceramic Resistors are characterized by high resistance values, high power handling capabilities, and the ability to effectively withstand high-energy and high-voltage pulse applications. The ceramic substrate provides the resistors with excellent thermal stability and mechanical strength, enabling them to perform well in harsh working environments. The resistors' high energy handling capacity makes them ideal for electronic circuits requiring rapid response and high-frequency loads. In addition, the laser trimming process ensures that each resistor meets the precise resistance value and size specifications required by the customer.

Ceramic High Value Resistors are widely used in various high-precision, high-power electronic devices, especially in applications requiring high resistance values and stable performance. They are crucial components in power electronics, communication equipment, industrial control systems, and medical instruments. Their reliability and high-voltage tolerance make them essential for handling high-energy pulses and environments with significant voltage fluctuations. Whether customized for specific applications or as general-purpose resistors, they meet the high-performance needs of demanding electronic circuits.

Manufacturing of High Value Ceramic Resistors :

● Preparation of Ceramic Substrate: The process starts with the preparation of a ceramic substrate, typically made from materials like aluminum oxide (Al2O3) or beryllium oxide (BeO), known for their high thermal and electrical insulation properties.

● Conductor Printing: Conductive materials such as silver (Ag) or silver/palladium (Ag/Pd) paste are screen-printed onto the ceramic substrate to form the electrodes. The paste is then dried and fired at high temperatures to create a solid conductive layer.

● Resistive Layer Coating: A resistive material, often a metal oxide like ruthenium dioxide (RuO2), is screen-printed onto the substrate in a pattern that determines the resistor's resistance value. This layer is then dried and fired at high temperatures to create a solid, resistive layer.

● Sintering Process: During sintering at elevated temperatures, binders and solvents in the slurry evaporate, resulting in the solidification of conductive particles and the formation of a continuous conductive path.

● Laser Trimming: The initial resistance value is trimmed to the desired value using a laser. The laser modifies the resistive layer by altering its dimensions.

● Glass Passivation: A protective glass layer is applied over the resistive layer to protect it from physical damage and environmental factors. This layer is also dried and fired at high temperatures.

● Testing and Sorting: Each resistor is tested for its resistance value and other electrical characteristics to ensure it meets the specified tolerances and performance requirements.

Features of Ceramic High Value Resistors :

● High Resistance Values: Engineered to provide precise and efficient control of voltage and current, the Ceramic High Value Resistor offers exceptionally high resistance values. This capability ensures optimal circuit performance and integrity.

● Superior Environmental Resistance: Demonstrating remarkable resilience against environmental stressors such as moisture, humidity, and corrosive agents, this resistor guarantees long-term reliability even in harsh operating conditions. It minimizes the risk of failure and enhances overall system durability.

● Temperature Stability: With outstanding temperature stability, the Ceramic High Value Resistor operates reliably across extreme temperature ranges. Its resistance remains unaffected by temperature fluctuations, ensuring consistent performance in challenging environments.

● Compact and Lightweight Design: Featuring a compact and lightweight construction, this resistor facilitates seamless integration into diverse electronic devices and systems. Its space-saving design optimizes PCB layouts and contributes to enhanced system efficiency.

● Low Noise and Distortion: High Ceramic Value Resistor delivers minimal noise and distortion levels, making it ideal for applications demanding high signal integrity. It effectively mitigates signal interference, enabling clear and precise transmission.

● High Voltage Handling Capacity: Engineered to withstand high voltage levels without compromising safety or performance, this resistor efficiently manages high power loads. It safeguards against voltage breakdowns, thereby prolonging the lifespan of electronic systems.

Applications of High Value Ceramic Resistors :

● Battery Management Systems: High Value Ceramic Resistors are used as pre-charge resistors to limit the inrush current during the start-up phase, protecting the main line capacitors from damage.

● Pulse Absorption: High-energy ceramic resistors can absorb high-energy pulses, making them suitable for applications requiring energy dissipation over short periods, such as in power electronics and motor controls.

● Overvoltage Protection: High Value Ceramic Resistors serve as protection elements in electronic devices to safeguard against voltage spikes, which is crucial in sensitive electronic equipment like computers and communication devices.

● Automotive Applications: Used in various automotive electronics for overvoltage protection and energy absorption, including in advanced driver-assistance systems (ADAS), control systems, and communication entertainment systems.

● Military and Aerospace: Due to their high reliability and ability to operate in extreme temperatures, high-value ceramic resistors are used in military and aerospace applications where stability and safety are paramount.

● High-Power Applications: High Value Ceramic Resistors are utilized in high-power circuits where traditional resistors may fail due to the heat generated. The solid construction of ceramic resistors allows them to withstand high power levels.

● Medical Equipment: In medical devices where precision and reliability are essential, high-value ceramic resistors provide stable resistance and protection against electrical surges.

● Industrial Controls: Used in industrial control systems for their ability to provide stable resistance under varying environmental conditions and to protect against voltage fluctuations.

● Telecommunications: In telecommunications equipment, they are used to protect against power surges and to ensure the reliable operation of sensitive communication equipment.

● Electronic Instruments: As part of the protection circuitry in electronic instruments to prevent damage from voltage spikes, especially in large-scale integrated circuits (LSI) and very-large-scale integrated circuits (VLSI).

Why Deed to Customize High Value Ceramic Resistors ?

● Precision and Stability: High Value Ceramic Resistors are needed in applications where precision is crucial. Customization allows for the creation of resistors with extremely tight tolerances and high stability, ensuring consistent performance over time and across varying environmental conditions.

● Unique Resistance Values: Standard resistors may not offer the exact resistance value required for a particular application. Custom High Value Ceramic Resistors can be manufactured to have specific resistance values that are not available in standard catalogs.

● Environmental Durability: Electronic devices used in harsh environments, such as aerospace or industrial applications, require components that can withstand extreme temperatures, humidity, and vibrations. Custom High Value Ceramic Resistors can be designed with materials and coatings that provide the necessary protection and longevity.

● Miniaturization: As technology advances, there is a constant demand for smaller and more compact electronic components. Custom High Value Ceramic Resistors can be designed to fit into tight spaces without compromising on performance.

● Power Handling: High Value Ceramic Resistors may need to handle specific power levels that are not accommodated by standard components. Customization allows for the design of resistors that can safely dissipate the required amount of heat.

● Noise Reduction: In sensitive applications, such as medical equipment or precision measurement devices, noise from electronic components can be a significant issue. Custom High Value Ceramic Resistors can be optimized to minimize noise interference.

● Long-term Supply Chain: Custom High Value Ceramic Resistors can be manufactured with a guaranteed supply, ensuring that as technology evolves, the specific components needed remain available and are not subject to obsolescence.

● Regulatory Compliance: Certain industries have strict regulatory requirements that standard components may not meet. Custom High Value Ceramic Resistors can be designed to comply with these regulations, ensuring the legality and safety of the end product.

● Technical Collaboration: Working with a manufacturer to customize a High Value Ceramic Resistors often involves a close collaboration that can lead to innovative solutions and a better understanding of the application's needs.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors