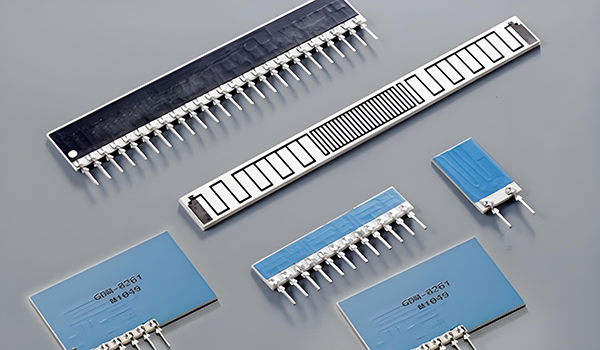

Thick Film Resistor Networks

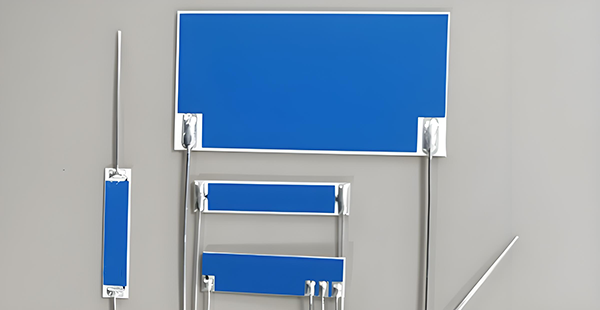

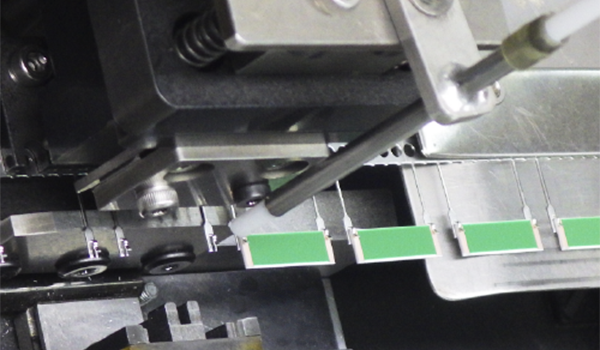

Thick Film Resistor Networks, also called Thick Film Network Resistors, are customizable electronic resistive components created by applying thick-film resistive material onto a ceramic substrate to form multiple resistor units or a resistor network, with these resistors functioning by determining the resistance value based on the thickness and size of the resistive layer, while the ceramic substrate provides electrical insulation, and this manufacturing process allows for the creation of resistors that can serve specific purposes in electronic circuits, such as high-value resistors, high-energy resistors, high-power resistors, or high-voltage divider resistors.

Thick Film Resistor Networks offer several key features, including the ability to integrate multiple resistive values into a single component, reducing the need for separate resistors in the circuit. These resistors are designed for high power handling, high resistance values, and stable performance over a wide range of temperatures and voltages. The thick-film construction gives them excellent durability, heat resistance, and the ability to perform well in harsh environmental conditions. The compact size and customizable resistance values make them ideal for use in space-constrained applications, where cost-efficiency and high performance are essential.

Thick Film Network Resistors are widely applied in numerous electronic devices and systems, such as power supplies, automotive electronics, communication equipment, and industrial control systems. They are used where high resistance, high power handling, and reliability are critical, such as in voltage dividers, filters, and other circuit functions requiring stable performance under demanding conditions. Their ability to be custom-designed to meet specific needs makes them versatile in both consumer electronics and industrial applications, providing cost-effective solutions for complex electronic circuit designs.

Features of Thick Film Resistor Networks :

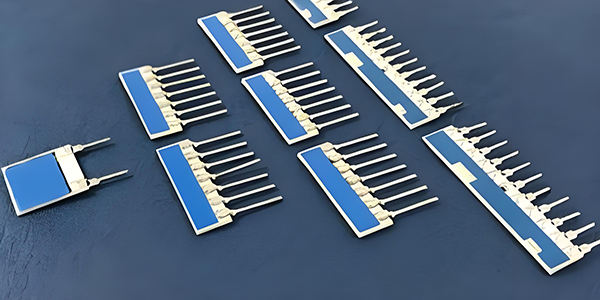

● Customizability: Thick Film Resistor Networks can be tailored to meet specific resistance requirements, allowing the creation of resistors with varying resistance values in a single component. This flexibility makes them suitable for a wide range of applications where precise resistance values are needed.

● High Power Handling: Thick Film Resistor Networks are designed to handle high power levels without degrading in performance, making them ideal for use in high-power circuits. They offer robust power dissipation and are often used in environments where power efficiency is critical.

● Durability and Heat Resistance: The thick-film construction of these resistor networks provides exceptional durability, allowing them to withstand high temperatures and harsh environmental conditions. This heat resistance ensures that they perform reliably in a variety of industrial and consumer applications, including automotive and power supply systems.

● Compact Size: Despite their high performance, thick film resistor networks come in compact sizes, which helps save space in electronic circuits. This makes them perfect for designs where minimizing space is a priority, such as in portable electronics and tightly packed circuit boards.

● Electrical Insulation: The ceramic substrate used in thick film resistor networks provides excellent electrical insulation, ensuring that the resistors function reliably and safely in various electronic environments. This insulation also enhances the stability and longevity of the components.

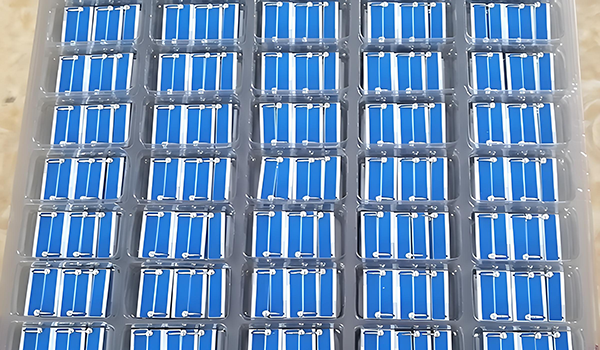

● Cost-Effectiveness: Due to their efficient manufacturing process, thick film resistor networks are cost-effective, especially for mass production. This makes them a preferred choice for many manufacturers looking for a balance between performance and cost in high-volume electronic products.

Design Consideration of Thick Film Network Resistors :

● Resistance Values: When designing a Thick Film Network Resistor, it is crucial to specify the exact resistance values needed for the application. These values must be carefully selected based on the circuit's requirements and performance expectations.

● Tolerance: Define the acceptable variation in resistance values, as tolerances are essential to ensure proper circuit functionality. Typical tolerances for thick film network resistors range from ±1% to ±5%, though more precise tolerance levels can be specified if necessary for the application.

● Temperature Coefficient (TCR): The temperature coefficient of resistance (TCR) must be considered to ensure the resistor network remains stable across varying temperatures. A low TCR is desirable for applications that require consistent performance in environments with fluctuating temperatures.

● Power Ratings: Ensure that the resistor network can handle the power dissipation requirements of the application without overheating or experiencing thermal failure. Proper power rating selection is critical for maintaining long-term reliability and performance in high-power circuits.

● Substrate Material: Choose the appropriate substrate material based on thermal and mechanical properties. Common materials include alumina (Al2O3), beryllia (BeO), and glass, each with distinct characteristics regarding thermal conductivity, insulation properties, and mechanical strength.

● Interconnection: Plan the method of interconnection to the rest of the circuit. This could involve techniques such as soldering, wire bonding, or the use of conductive adhesive, depending on the design requirements, space constraints, and overall application.

● Environmental Factors: Account for the environmental conditions the resistor network will be exposed to. This includes factors such as vibration, shock, humidity, temperature extremes, and potential chemical exposure. These conditions can affect the long-term reliability and performance of the network, so selecting appropriate materials and coatings for protection is crucial.

Applications of Thick Film Resistor Networks :

● Medical Equipment: Thick film resistor networks are widely used in medical devices, especially in precision instruments where small size, reliability, and long-term stability are essential. These resistors ensure accurate readings and reliable performance in critical healthcare applications.

● Telecommunications: In telecommunications, thick film resistor networks are employed in filters and signal processing circuits. Their ability to handle high power and maintain stable resistance over a wide temperature range makes them ideal for communication devices, where signal integrity is paramount.

● Automotive Electronics: Thick film resistor networks are integral to automotive electronics, particularly in engine control units (ECUs) and safety systems. Their robustness and ability to withstand harsh environmental conditions such as temperature extremes, vibrations, and electromagnetic interference make them essential in ensuring reliable performance in modern vehicles.

● Consumer Electronics: These resistor networks are commonly found in a variety of consumer electronics, such as smartphones, televisions, and audio equipment. They are used for signal conditioning, voltage regulation, and filtering to maintain high-quality performance and energy efficiency in compact, space-constrained devices.

● Industrial Controls: In industrial control systems, thick film resistor networks are used to maintain precision and reliability under demanding conditions. These resistors are employed in process control, automation, and monitoring systems that operate in harsh environments, where stability and accuracy are critical for safety and performance.

● Military and Aerospace: Known for their high reliability and precision, thick film resistor networks are trusted in military and aerospace applications, where performance in extreme conditions is crucial. They are used in avionics, satellite systems, radar equipment, and defense electronics, where failure is not an option.

● Computing and Networking: Thick film resistor networks are incorporated into computer motherboards and networking hardware to perform signal routing, conditioning, and voltage regulation. Their compact size and high durability make them ideal for use in densely packed, high-performance systems such as servers, routers, and switches.

Why Deed to Customize Thick Film Resistor Networks ?

● Specific Application Requirements: Custom Thick Film Resistor Networks can be tailored to meet the unique electrical specifications of different applications, ensuring optimal performance.

● Precision and Consistency: Custom Thick Film Resistor Networks offer precise resistance values and tight tolerances, which are crucial for maintaining consistent performance in electronic circuits.

● Space and Efficiency: By designing resistor networks to fit specific spaces, they can be made more compact, which is particularly valuable in applications with limited space, such as portable electronics.

● Cost-Effectiveness: While there may be an initial investment in customization, it can lead to cost savings over time by reducing the need for modifications and replacements.

● Reliability and Durability: Custom Thick Film Resistor Networks can be built to be more reliable and durable, with resistance to environmental factors such as temperature fluctuations and humidity.

● Integration and Compatibility: Custom Thick Film Resistor Networks can be designed to integrate seamlessly with other components in a system, reducing the potential for compatibility issues.

● Performance Optimization: They can be optimized for specific performance characteristics, such as low noise or high stability, which are necessary for high-precision applications.

● Regulatory Compliance: Custom Thick Film Resistor Networks can be designed to meet industry-specific regulatory standards, which is vital for products that must adhere to strict compliance guidelines.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors