Thick Film Non-Inductive Resistors

Thick Film Non-Inductive Resistors, also called Ceramic Non-Inductive Resistors, are specially designed resistor devices that ensure stable resistance values without generating inductance, and they are manufactured using thick film technology by printing a metal film onto a ceramic or glass substrate; this design eliminates the inductive effects typically seen in traditional wirewound resistors, resulting in high-frequency performance and precise resistance control, making them crucial in applications where stable, non-inductive behavior is required and offering superior performance in high-frequency circuits.

Thick Film Non-Inductive Resistors are known for their excellent resistance stability and precision, making them ideal for demanding applications. With a wide range of resistance values and high power handling capabilities, they can handle diverse circuit requirements. These resistors are distinguished by their lack of coiled structures, which prevents inductance and allows for superior performance in high-frequency and high-power applications. Additionally, their ceramic or glass substrate provides durability and excellent thermal stability, ensuring reliable performance even in extreme environments. The absence of inductance allows for more accurate signal transmission, making these resistors a key component in precision electronic systems.

Ceramic Non-Inductive Resistors are widely used across various industries due to their stability, high-frequency capabilities, and versatility. In power management circuits, these resistors help maintain consistent performance under varying conditions. They are also commonly used in sensors, control systems, communication equipment, automotive electronics, medical devices, and industrial automation. In each of these applications, the ability to manage power, minimize signal interference, and operate efficiently in high-frequency settings makes Non-Inductive Resistors an essential component. Their reliability and precision also contribute to the safety and performance of critical systems in automotive and medical applications.

Features of Thick Film Non-Inductive Resistors :

● Non-Inductive: Due to its special design and thick film process, the thick film non-inductive resistor does not generate any inductive effects, such as magnetic fields or inductance, during operation.

● High Stability: It exhibits excellent temperature stability and frequency response characteristics, maintaining a stable resistance value under different operating conditions.

● High Power Handling Capability: Compared to thin film resistors, thick film non-inductive resistors have a higher power handling capacity, enabling stable operation at higher currents and power levels.

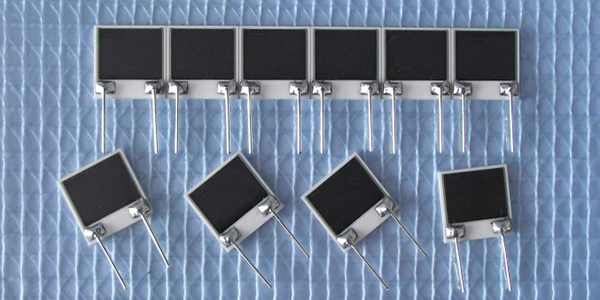

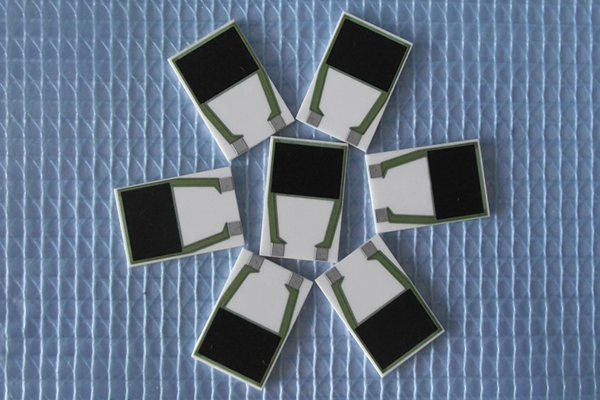

● Various Packaging Options: They can be packaged in different forms, such as surface mount, axial, radial, etc., making them easy to install and use on different circuit boards.

● Temperature Coefficient: Thick Film Non-Inductive Resistors typically have a temperature coefficient, which means that their resistance value changes slightly with variations in temperature. This characteristic needs to be considered in certain applications as it may affect circuit performance and accuracy.

● Rated Power and Rated Voltage: Thick Film Non-Inductive Resistors need to consider their rated power and rated voltage during operation. The rated power refers to the maximum power that the resistor can continuously withstand, while the rated voltage indicates the maximum voltage at which the resistor can safely operate.

● Size and Packaging: The size and packaging of Thick Film Non-Inductive Resistors may vary depending on specific application requirements. Common packaging forms include surface mount, axial, radial, etc., and different packaging forms are suitable for different devices and circuit board layouts.

● Variable Resistors: In addition to fixed-value Thick Film Non-Inductive Resistors, there are also variable thick film non-inductive resistors available. Variable resistors allow users to adjust the resistance value as needed, providing greater flexibility and adaptability.

Functions of Thick Film Non-Inductive Resistors :

Thick Film Non-Inductive Resistors are specially designed resistors that aim to reduce the inductive effects that occur when current flows through the resistor. These resistors are widely used in high-frequency and power-sensitive electronic circuits. Below are the key functions and features of these resistors:

1. Providing Impedance Function.

● Basic Function: The core function of thick film non-inductive resistors is to provide a stable resistance value and limit the current flowing through the circuit. This helps maintain stable current flow in the circuit and ensures the proper functioning of each part of the circuit.

2. Reducing Inductive Effects.

● Suppressing Inductance: Traditional resistors can generate inductive effects due to their structure or geometry, which can impact current flow and interfere with high-frequency signals. Thick film non-inductive resistors are designed with special configurations (e.g., optimized resistor materials and layouts) to minimize inductive effects. This is especially important in high-frequency circuits, as it prevents signal distortion or increased noise.

3. High Power Handling Capability.

● Power Tolerance: These resistors are capable of handling higher power loads and are commonly used in circuits that require significant heat dissipation. They are widely applied in high-power environments such as power supply modules and power amplifiers, where they can operate stably under high power conditions.

4. Temperature Stability.

● Low Temperature Coefficient (TCR): Thick film non-inductive resistors have a low temperature coefficient, meaning their resistance value changes very little with temperature. This makes them suitable for applications that require high precision and temperature stability, even in environments with significant temperature fluctuations.

5. High-Frequency Performance.

● Suitable for High-Frequency Circuits: Thick film non-inductive resistors are particularly suitable for high-frequency applications. Their design minimizes inductive effects, making them perform well in RF (radio frequency) circuits, microwave circuits, and other applications where precise control of high-frequency signals is essential.

6. Precise Current Sensing.

● Current Measurement: These resistors are often used in current sensing circuits, especially in battery management systems, switching power supplies, and overcurrent protection circuits. They provide accurate current measurement, helping to ensure the safety and stability of the system.

7. Variety and Adjustability.

● Flexibility: While most thick film non-inductive resistors have fixed resistance values, some designs allow fine adjustments of their size or materials to achieve precise resistance values, catering to various circuit design needs.

Applications of Thick Film Non-Inductive Resistors:

● Power Management Circuits: Thick Film Non-Inductive Resistors are widely used in various power management circuits where precise and stable resistance values are required. These circuits include voltage regulators, power converters, and battery management systems. The resistors help regulate voltage levels, control current flow, and ensure efficient power distribution within the circuit.

● Sensors and Measurement Devices: In sensor and measurement applications, accuracy and reliability are critical. Thick Film Non-Inductive Resistors are employed in sensor interface circuits, signal conditioning circuits, and precision measurement instruments such as multimeters and oscilloscopes. They assist in signal amplification, filtering, and impedance matching, contributing to accurate sensor readings and data acquisition.

● Control Circuits and Regulation Circuits: Thick Film Non-Inductive Resistors play a vital role in control circuits and regulation circuits across various industries. They are utilized in feedback networks, feedback loops, and control systems to maintain desired operating conditions and achieve stability. Applications include temperature control systems, motor speed controllers, and process automation equipment.

● Communication Equipment and Signal Processors: Communication equipment and signal processing devices require high-performance resistors to ensure signal integrity and minimize signal distortion. Thick Film Non-Inductive Resistors are integrated into amplifiers, filters, equalizers, and impedance matching networks in telecommunications, networking devices, and audio/video equipment. They help optimize signal transmission, reduce noise, and improve overall system performance.

● Automotive Electronic Systems: Automotive electronic systems demand robust and reliable components capable of withstanding harsh environmental conditions and automotive-grade specifications. Thick Film Non-Inductive Resistors are utilized in automotive applications such as engine control units (ECUs), transmission control modules (TCMs), electronic stability control (ESC) systems, and airbag deployment systems. They contribute to the safety, efficiency, and performance of modern vehicles by providing accurate resistance values and stable operation in automotive environments.

● Medical Devices and Instrumentation: In medical device manufacturing and instrumentation, precision and consistency are paramount. Thick Film Non-Inductive Resistors are employed in medical imaging equipment, patient monitoring devices, and diagnostic instruments. They assist in signal processing, data acquisition, and feedback control loops, ensuring accurate measurements and reliable operation in medical applications.

● Industrial Automation and Robotics: Thick Film Non-Inductive Resistors find extensive use in industrial automation, robotics, and control systems. They are incorporated into programmable logic controllers (PLCs), motion control systems, and robotic arms to regulate motor speed, monitor sensor inputs, and control actuators. The resistors facilitate efficient automation processes, enhance productivity, and improve manufacturing efficiency in industrial settings.

Thick Film Non-Inductive Resistors are versatile components with diverse applications across numerous industries, contributing to the functionality, performance, and reliability of various electronic systems and devices.

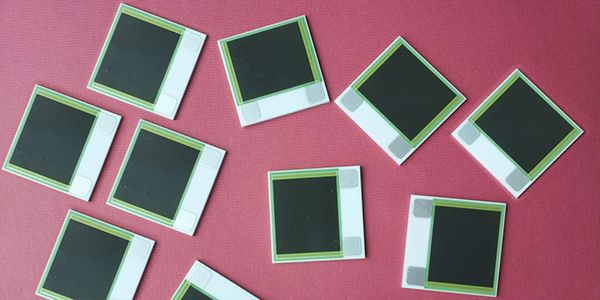

Manufacturing of Ceramic Non-Inductive Resistors :

● Substrate Preparation: Selecting suitable ceramic or glass substrates as carriers.

● Film Printing: Using thick film printing technology to print metal films on the substrate surface.

● Sintering and Curing: Subjecting the printed films to sintering treatment, solidifying them, and bonding them to the substrate.

● Process Inspection: Conducting strict process inspections on the finished resistor devices to ensure compliance with specifications and quality requirements.

● Packaging and Testing: Packaging the resistor devices as per requirements and conducting final performance testing and quality inspection.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors