High Power Ceramic Resistors

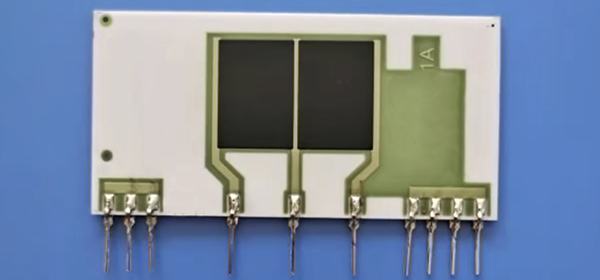

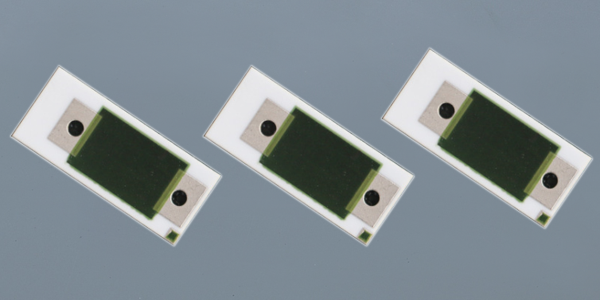

High Power Ceramic Resistors, also called Ceramic High Power Resistors, are specialized components designed to handle high electrical power, produced using thick-film technology where a resistive film made of metal oxides and glass is printed onto a ceramic substrate, allowing for high power ratings and customizable resistance values to meet specific needs while ensuring heat dissipation and operational stability in high-power environments, making them ideal for a wide range of high-energy applications.

High Power Ceramic Resistors offer several unique features that make them suitable for demanding power applications. One of the primary advantages is their high power handling capacity, allowing them to safely dissipate large amounts of electrical energy without failure. They are made from materials with excellent thermal conductivity, which ensures efficient heat dissipation, preventing overheating and ensuring stable operation over long periods. The thermal stability of these resistors is another critical feature; they can withstand rapid temperature changes and extreme heat without suffering from performance degradation. Additionally, these resistors have mechanical durability, which makes them resistant to physical stress, vibration, and environmental factors such as moisture or corrosion. This rugged construction and reliability make them ideal for use in harsh industrial and aerospace environments.

Ceramic High Power Resistors are widely used in various industries where high power dissipation and reliability are essential. In power electronics, they are integral to power converters, inverters, and high-power amplifiers, where they manage large electrical currents and ensure efficient energy conversion. These resistors are also critical in pulsed power systems, including radar, medical equipment (such as defibrillators), and particle accelerators, where rapid energy pulses are required. In the military and aerospace sectors, they are used in satellite systems, avionics, and communication equipment, where performance and reliability in extreme conditions are essential. Industrial control systems also rely on these resistors for motor drives, power supplies, and process control systems, where high power and precision are necessary. Additionally, High Power Ceramic Resistors are key components in RF and microwave systems, where they help manage high-frequency signals and dissipate associated energy. Lastly, they play a role in energy storage and conversion systems, such as in battery management and renewable energy applications, where they improve system efficiency by safely handling excess energy.

Advantages of High Power Ceramic Resistors :

● High Power Handling: High Power Ceramic Resistors are designed to handle large amounts of electrical power without compromising performance. Their robust construction and advanced materials allow them to dissipate heat efficiently, making them ideal for applications requiring high power dissipation.

● Thermal Stability: These resistors are known for their excellent thermal stability, enabling them to perform reliably even under extreme temperature variations. This quality ensures they can handle thermal stress without degradation, which is crucial in environments with fluctuating heat levels.

● Durability and Reliability: Due to their ceramic-based construction, High Power Ceramic Resistors are highly durable and resistant to environmental factors such as moisture, dust, and vibrations. This makes them suitable for use in demanding conditions, including military, aerospace, and industrial applications.

● Customizability: High Power Ceramic Resistors can be tailored to meet specific application requirements, with customizable resistance values, power ratings, and physical dimensions. This adaptability makes them versatile across a wide range of industries.

● Efficient Heat Dissipation: The thick-film technology used in their construction allows for efficient heat dissipation, reducing the risk of overheating and ensuring stable operation. This is especially important in applications where high currents and voltages are involved.

● Compact Design: Despite their high power handling capabilities, High Power Ceramic Resistors are often compact in size, allowing for use in applications with limited space while maintaining high performance.

● Cost-Effective: While high-power resistors can often be expensive, the manufacturing process of High Power Ceramic Resistors offers a cost-effective solution for many applications without sacrificing reliability or performance.

Applications of Ceramic High Power Resistors :

● Power Electronics: Ceramic High Power Resistors are used in power converters, inverters, and high-power amplifiers where high current and voltage are involved.

● Automotive: Ceramic High Power Resistors are found in various automotive applications, including engine control systems and power management circuits.

● Industrial Control Systems: Utilized in motor drives, power supplies, and process control systems that require high-energy resistance and precision.

● Medical Equipment: Employed in medical imaging and other high-precision medical devices where reliability and stability are paramount.

● Military and Aerospace: Used in applications where high reliability and the ability to withstand extreme conditions are critical, such as in satellite systems and military communication equipment.

● RF and Microwave Systems: Ceramic High Power Resistors can be used in the design of radio frequency (RF) and microwave components, where they help control and dissipate the high energy associated with these frequencies.

● Energy Storage and Conversion: Ceramic High Power Resistors are also used in systems that involve the storage and conversion of energy, such as in battery management systems and renewable energy applications.

Why Deed to Customize High Power Ceramic Resistors ?

● Precision and Accuracy: Custom High Power Ceramic Resistors can be made to exact specifications, ensuring that they meet the precise requirements of the application they are designed for.

● Performance Optimization: High power applications often require resistors that can handle high temperatures and currents. Customization allows for the design of resistors that are optimized for these conditions.

● Reliability and Durability: Custom High Power Ceramic Resistors can be built to last longer and be more reliable under the specific conditions they will be used in.

● Cost Efficiency: While there may be an initial cost associated with customization, in the long run, it can lead to cost savings by reducing the need for frequent replacements and minimizing failures.

● Space Efficiency: Custom High Power Ceramic Resistors can be designed to fit into specific spaces, which is particularly important in applications where space is at a premium.

● Compatibility: High Power Ceramic Resistors can be tailored to work seamlessly with other components in a system, reducing the risk of compatibility issues.

● Innovative Solutions: Custom High Power Ceramic Resistors allow for the development of innovative solutions that off-the-shelf products might not be able to provide.

● Regulatory Compliance: Custom High Power Ceramic Resistors can be designed to meet specific regulatory standards, which is essential for industries that are heavily regulated.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Resistors

- Custom Thick Film Resistor Elements

- High Voltage Ceramic Resistors

- High Value Ceramic Resistors

- High Energy Ceramic Resistors

- High Power Ceramic Resistors

- Humidity Sensitive Ceramic Resistors

- Thick Film Non-Inductive Resistors

- Thick Film Planar Resistors

- Thick Film Tubular Resistors

- Thick Film Resistor Networks

- Thick Film Surge Resistors

- Radio Frequency Power Resistors

- High Voltage Divider Resistors

- Ceramic Variable Resistors