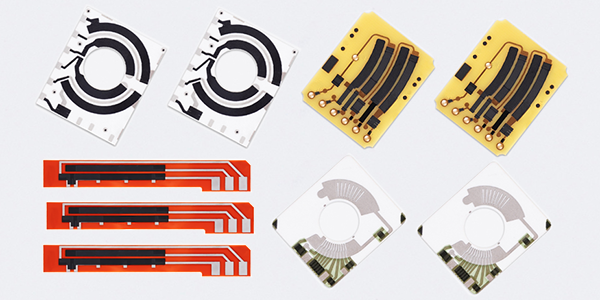

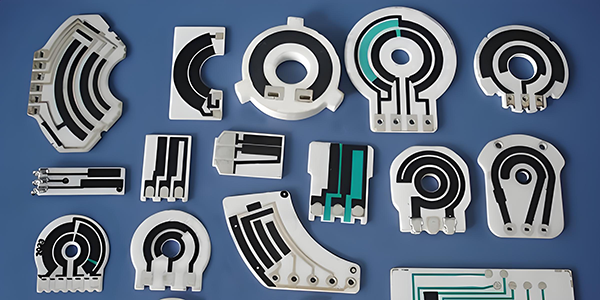

Custom Thick Film Sensor Elements

Custom Thick Film Sensor Elements are specialized sensor components designed and manufactured using thick film technology, tailored to meet specific application needs and offering greater flexibility than standard sensors, allowing them to be optimized for particular functions and performance requirements with customization in size, shape, material composition, and other features to suit applications where standard sensors may not meet the exact specifications, enabling their use across a wide range of industrial and commercial sectors that require high precision and specialized performance.

Custom Thick Film Sensor Elements are produced through a precise thick film technology process, where materials are applied in layers onto a substrate. This manufacturing method allows for strict control over the material properties and thickness of each layer, ensuring that the final sensor component meets the desired electrical and mechanical characteristics. The process enables the integration of various materials, including conductive pastes and resistive films, to achieve the specific durability, performance, and reliability needed for each application, making the sensors adaptable to a wide variety of conditions and environments.

Custom Thick Film Sensor Elements are known for their versatility and resilience in challenging environments. They can be designed to function under extreme temperatures, high humidity, or corrosive conditions. The technology also offers a wide selection of material options, including conductive and insulating materials, which ensures the sensors' adaptability to diverse measurement requirements. This range of customization not only optimizes sensor performance but also enhances their longevity and reliability, making them suitable for long-term use in demanding applications.

Custom Thick Film Sensor Elements are widely used in various industries, such as automotive, medical, industrial automation, and consumer electronics. Their ability to provide accurate and durable measurements in systems like temperature, pressure, humidity, and gas detection makes them invaluable in applications where precision is essential. The adaptability and customization options of these sensors make them particularly well-suited for industries that require sensors to operate under unique or extreme conditions, ensuring high performance across diverse technological fields.

Overview of Custom Thick Film Sensor Elements :

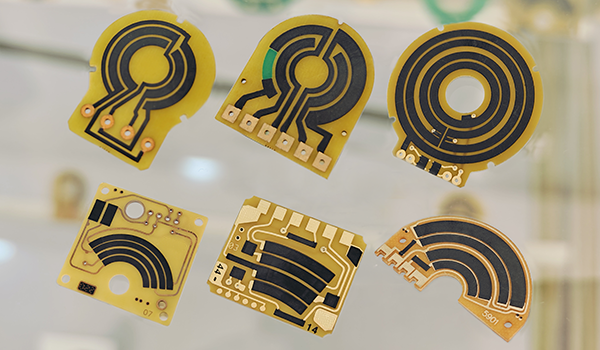

● Technology: Custom Thick Film Sensor Elements are made using thick film technology, a type of circuit fabrication process that involves printing a thick layer of material (usually a conductor, resistor, or dielectric) onto a substrate to form electronic circuits or components.

● Customization: The term "customized" indicates that these sensors are not mass-produced with a one-size-fits-all approach but are instead tailored to meet particular customer specifications.

● Materials: Custom Thick Film Sensor Elements often use a combination of materials such as ceramics, glass, or polymers as substrates, and noble metals, oxides, or other conductive materials for the thick film layers.

● Applications: Custom Thick Film Sensor Elements are used in a wide range of applications where specific sensing capabilities are needed, including automotive, medical, industrial, and environmental monitoring.

● Advantages: They offer advantages such as high precision, reliability, the ability to withstand harsh environments, and the flexibility to be designed for unique measurement ranges and sensitivities.

● Design: The design of these sensors can be modified in terms of size, shape, resistance value, temperature coefficient, and other parameters to suit the application's needs.

● Integration: Custom Thick Film Sensor Elements can be integrated with microelectronic circuits for signal processing, providing a complete sensing and processing solution.

● Development: The development process involves close collaboration between the customer and the manufacturer to ensure that the final product meets all the required specifications.

● Examples: Examples of custom thick film sensor elements include pressure sensors for engines, temperature sensors for medical devices, or chemical sensors for environmental monitoring.

Custom Thick Film Sensor Elements are precision-engineered devices that leverage the versatility of thick film technology to create sensors that are optimized for specific applications, offering a high degree of customization and performance.

Advantages of Custom Thick Film Sensor Elements :

Custom Thick Film Sensor Elements offer several advantages that can be critical for specialized applications where off-the-shelf sensors may not suffice. Here are some of the key advantages:

● Specificity: Tailored to meet precise measurement requirements, ensuring accurate and reliable data for the intended application.

● Enhanced Durability: Designed with materials and construction techniques to withstand the rigors of their operating environment, leading to a longer service life.

● Environmental Adaptability: Custom sensors can be made resistant to extreme temperatures, corrosive chemicals, and other environmental factors, making them suitable for harsh conditions.

● Improved Performance: Optimization for specific parameters such as sensitivity, response time, and stability can result in superior performance compared to generic sensors.

● Space Efficiency: Customization allows for the development of sensors that fit into tight spaces, which is crucial for applications with limited room for sensor placement.

● Seamless Integration: Sensors can be designed to work harmoniously with existing systems, matching communication protocols, electrical connections, and data formats.

● Regulatory Compliance: Custom Thick Film Sensor Elements can be created to meet industry-specific standards and regulations, ensuring legal and safety requirements are adhered to.

● Cost-Customization: While there may be initial development costs, the long-term cost can be optimized by avoiding over-engineering and ensuring the sensor performs only the necessary functions.

● Innovation: Customization enables the creation of innovative solutions to complex sensing problems, pushing the boundaries of what's possible with standard sensors.

● Reduced Risk of Error: By precisely matching the sensor to the application, the risk of incorrect measurements or sensor failures is minimized.

● Enhanced Data Quality: With tailored sensitivity and response characteristics, custom sensors can provide higher-quality data, which is essential for critical applications.

● Competitive Edge: Utilizing customized sensors can provide a technological advantage in industries where precision and reliability are key differentiators.

● Supply Chain Optimization: Custom Thick Film Sensor Elements can help companies optimize their supply chain by reducing reliance on multiple suppliers for different sensor types.

● Custom Features: Additional features such as built-in diagnostics, self-test capabilities, and security measures can be integrated into custom sensors.

● Long-term Partnerships: Working with a manufacturer to develop a customized sensor can lead to a strong partnership, ensuring ongoing support and product evolution.

● Market Adaptability: Custom sensors allow companies to quickly adapt to changing market needs and technological advancements.

Applications of Custom Thick Film Sensor Elements :

Custom Thick Film Sensor Elements are versatile components that find applications across a spectrum of industries due to their precision, durability, and the ability to tailor their properties to specific requirements. Here are some applications of these sensors:

● Automotive Industry: For monitoring parameters like engine oil pressure, throttle position, fuel level, and temperature in engines.

● Medical Equipment: In devices that require precise control of fluid levels or pressure, such as infusion pumps and respiratory devices.

● Industrial Control Systems: To measure and control variables like pressure, temperature, and flow in manufacturing processes.

● Aviation and Aerospace: For in-flight systems that need to monitor fuel levels, pressures, and other critical parameters.

● Energy Sector: In oil and gas exploration for monitoring well pressures and temperatures.

● HVAC Systems: To control and monitor the flow of liquids and gases for heating, ventilation, and air conditioning systems.

● Environmental Monitoring: For detecting and measuring pollutants, radiation, or chemical concentrations.

● Consumer Electronics: In appliances like washing machines, dishwashers, and refrigerators for level detection and control.

● Telecommunications: For monitoring the performance of equipment and ensuring the stability of communication networks.

● Food and Beverage Industry: To monitor liquid levels in processing and storage tanks.

● Marine Applications: For monitoring fuel levels and pressures in ships and submarines.

● Research and Development: In laboratories for precise measurements and data collection in experiments.

● Building Automation: For smart buildings to control energy consumption by monitoring and adjusting systems like lighting and climate control.

● Power Generation: To monitor and control the levels of various fluids in power plants.

● Agricultural Technology: For monitoring moisture levels in soil and the levels of chemicals in agricultural processes.

● Waste Management: To monitor the levels of waste in treatment facilities and ensure efficient operation.

● Transportation: In trains and trams for monitoring the levels of various fluids necessary for operation.

● Fire Safety Systems: To detect and measure water levels in fire suppression systems.

Why Deed to Custom Thick Film Sensor Elements ?

● Specific Measurement Needs: Different applications require sensors with unique sensitivity, range, and accuracy. Custom Thick Film Sensor Elements allow for the creation of sensors that meet these specific measurement parameters.

● Environmental Conditions: Custom Thick Film Sensor Elements can be tailored to withstand particular environmental conditions such as extreme temperatures, corrosive chemicals, or high-pressure environments, which off-the-shelf sensors may not be able to handle.

● Integration with Existing Systems: Organizations often need sensors that can seamlessly integrate with their existing systems or infrastructure. Custom Thick Film Sensor Elements can be designed to match the required interface and communication protocols.

● Improved Performance: Customization can enhance the performance of sensors, including faster response times, better stability, and higher precision, which are critical for certain applications.

● Miniaturization: For applications where space is at a premium, custom Thick Film Sensors can be designed to fit into compact spaces without compromising functionality.

● Long-Term Reliability: Customized sensors can be built to last longer in specific operating conditions, reducing the need for frequent replacements and minimizing maintenance costs.

● Regulatory and Compliance Requirements: Certain industries have strict regulatory requirements for the equipment used. Custom sensors can be designed to meet these specific standards.

● Cost Efficiency: While there may be an initial investment in custom sensor development, the long-term cost savings from having a sensor that is perfectly suited to the application can be significant.

● Innovative Solutions: Customization allows for the development of innovative solutions to complex sensing challenges that cannot be addressed by standard sensors.

● Brand Differentiation: Offering customized products can help a company differentiate itself in the market by demonstrating a commitment to meeting customer needs precisely.

● Reduced Interference: Custom sensors can be designed to minimize interference from other electronic devices in the application environment.

● Enhanced Security Features: For applications where sensor data is sensitive, custom sensors can include additional security features to protect against tampering or unauthorized access.

Customizing Thick Film Sensors enables companies to create highly specialized sensing solutions that can provide a competitive edge through improved product performance, reliability, and customer satisfaction.

Design Considerations of Custom Thick Film Sensor Elements :

● Material Selection: The choice of materials for the thick film can greatly affect the sensor's performance, including the selection of conductive, resistive, and dielectric materials that are optimized for the intended application.

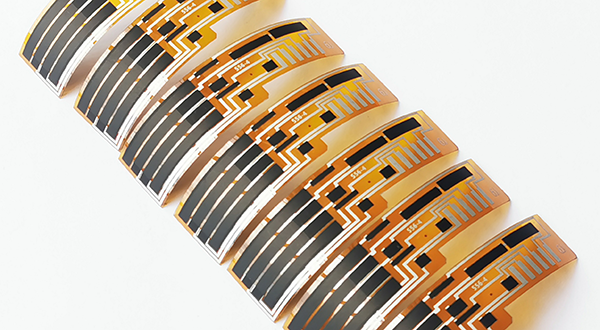

● Miniaturization: Advances in thick film technology allow for the creation of sensors that are smaller in size, making them suitable for applications where space is at a premium.

● Environmental Sustainability: The manufacturing process of thick film sensors can be more environmentally friendly compared to other sensor technologies, as it often requires less material and energy.

● Smart Sensor Integration: With the integration of microcontrollers and wireless communication modules, Customized Thick Film Sensors can become smart sensors capable of data processing and transmission, enhancing their utility in IoT applications.

● Regulatory Compliance: Depending on the industry, these sensors may need to comply with various regulatory standards, such as those for medical devices or automotive components, which is achievable through customization.

Custom Thick Film Sensor Elements represent a significant advancement in sensor technology, offering a high degree of flexibility and precision that is essential for many modern applications.

For more information, Please refer to Thick Film Sensors.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

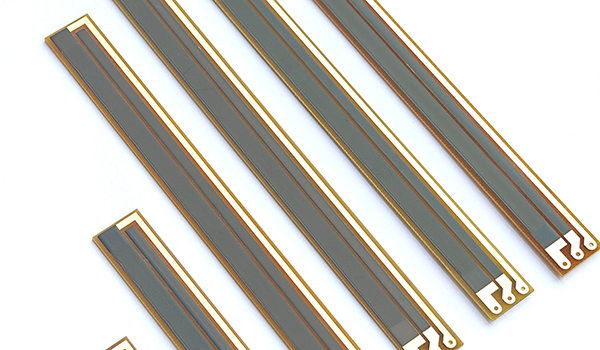

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

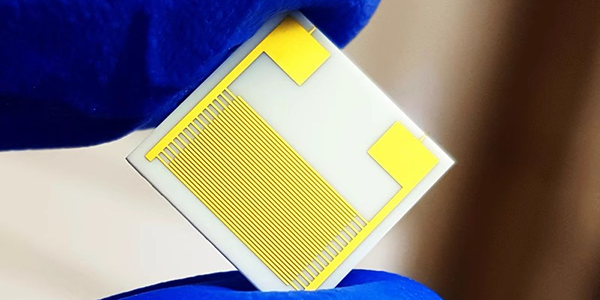

- Ceramic Position Sensor Carbon PCB

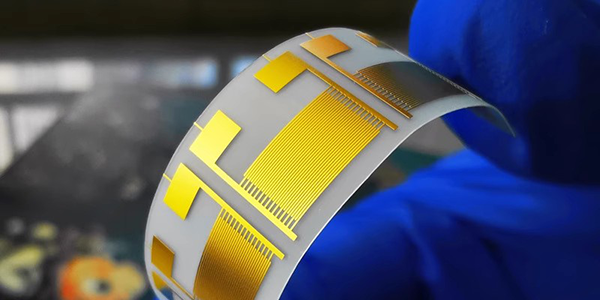

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

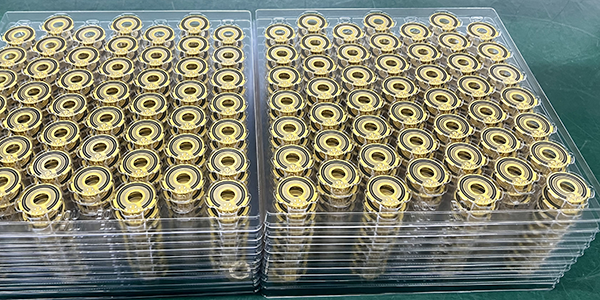

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB