LP Gas Tank Gauge Ceramic PCB

LP Gas Tank Gauge Sender Ceramic PCBs, also called Propane Tank Gauge Monitor Ceramic PCBs, are specialized components designed to monitor the liquid level inside liquefied petroleum gas (LPG) tanks, operating on resistance-based technology where their resistance value changes in response to fluctuations in the liquid level, with these changes detected in real-time by a remote transmitter that sends the data to a central control system which processes the information to monitor the liquid level and issue alerts when the tank reaches critical thresholds, ensuring safe usage and preventing gas-related hazards.

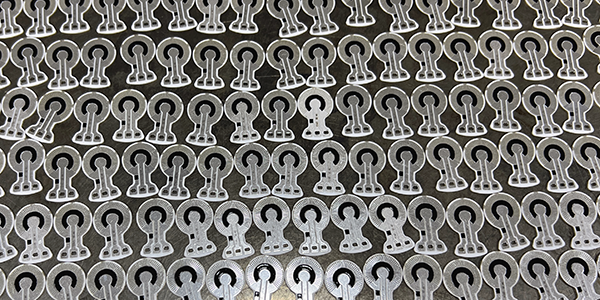

LP Gas Tank Gauge Sender Ceramic PCBs are produced using advanced thick-film hybrid circuit technology. The manufacturing process begins by screen-printing conductive and resistive pastes onto a ceramic substrate, which is then sintered at high temperatures to create the variable resistor circuit. The ceramic material offers excellent thermal stability, corrosion resistance, and mechanical strength, making the PCB ideal for harsh environments. This ensures that the device remains reliable and durable, even in extreme conditions, providing long-term performance in gas tank applications and other industrial uses.

Propane Tank Gauge Monitor Ceramic PCBs are known for their high accuracy and real-time monitoring capabilities. As the liquid level in an LPG tank changes, the resistance of the PCB fluctuates accordingly. This real-time data is transmitted to a central control system, allowing for continuous monitoring. The system can issue alerts when gas levels approach critical thresholds, preventing gas shortages or overflows. The combination of precise liquid level tracking, robust design, and timely alerts makes these PCBs a reliable choice for ensuring safe and efficient gas usage.

Propane Tank Gauge Monitor Ceramic PCBs are widely used in remote monitoring systems for LPG tanks, making them an essential part of modern gas management. By providing continuous, real-time tracking of liquid levels, these PCBs reduce the need for manual inspections, lowering labor costs and improving safety. Their high accuracy and durability make them suitable for industrial, commercial, and residential applications. They are particularly useful in LPG supply chain management, gas alarm systems, and other settings that require real-time data transmission and monitoring for effective and safe gas management.

Applications of LP Gas Tank Gauge Sender Ceramic PCB :

● LPG Tank Monitoring:

The primary application of this sensor PCB is for monitoring LPG tanks in industrial, commercial, and residential settings. It ensures that the gas supply is used efficiently and safely, reducing the risk of accidents due to gas shortages or overfilling.

● Remote LPG Management:

In LPG distribution systems, this LP Gas Tank Gauge Sender Ceramic PCB is used to enable remote monitoring of gas tank levels. This allows operators to manage tank refills more effectively and optimize supply chains, as well as alerting them to any abnormal levels that may indicate a problem.

● Safety and Compliance:

By providing accurate and continuous monitoring, the LP Gas Tank Gauge Sender Ceramic PCB helps ensure that LPG tanks are used within safe operational limits. It also assists in maintaining compliance with safety regulations and standards for gas storage and distribution.

● Industrial Applications:

In industries where LPG is used for heating, cooking, or power generation, the PCB ensures that gas levels are constantly monitored and managed to prevent disruptions to operations and minimize the risk of leaks or accidents.

LP Gas Tank Gauge Sender Ceramic PCBs are essential components in modern gas management systems. By providing accurate, real-time data on liquid levels in LPG tanks, they enhance safety, efficiency, and reliability, making them key technologies for both commercial and residential applications. The PCBs' durable, temperature-resistant designs ensure consistent performance even in challenging conditions, while their ability to be integrated into remote monitoring systems allows for proactive and efficient gas tank management.

How Propane Tank Gauge Monitor Ceramic PCB Works ?

Propane Tank Gauge Monitor Ceramic PCBs are specialized circuit boards designed to measure and monitor the liquid level inside LPG (Liquefied Petroleum Gas) tanks. These PCBs operate on the principle of resistance variation, where the resistance changes in response to fluctuations in the liquid level, providing accurate, real-time monitoring and ensuring safe usage of LPG.

● Variable Resistance Design:

Propane Tank Gauge Monitor Ceramic PCBs are equipped with resistive elements that alter their resistance as the liquid level in the LPG tank changes. These resistors are typically based on ceramic substrates, which offer exceptional durability, heat resistance, and stability across a wide range of environmental conditions, ensuring reliable performance over time.

● Matrix Resistor Array:

The PCB utilizes a matrix of resistive elements arranged in a specific pattern. This matrix is directly linked to the liquid level inside the tank, where the resistance changes depending on the position of the liquid. As the liquid level rises or falls, the resistance across these elements adjusts accordingly, enabling highly precise measurement of the liquid level.

● High Temperature and Corrosion Resistance:

Operating in harsh conditions, including temperature fluctuations and potential exposure to corrosive substances, Propane Tank Gauge Monitor Ceramic PCBs are designed for longevity and durability. The ceramic substrate’s resistance to high temperatures and chemical corrosion ensures that the PCB continues to perform reliably even under challenging conditions, making it highly suitable for long-term use in LPG tanks.

● Real-Time Monitoring:

The resistance changes on the PCB are detected in real-time by an electronic system, typically a remote ohm transmitter. The collected data is then transmitted to a central control system or monitoring interface. This system allows continuous tracking of the gas tank's liquid level and provides immediate feedback to operators or users, ensuring ongoing safety and operational efficiency.

● Accurate Level Detection:

The high precision of Propane Tank Gauge Monitor Ceramic PCBs allow for accurate detection of the liquid level. By monitoring this data, the system can provide early warning alerts when the tank reaches critical levels, such as too low or too high, preventing issues like overfilling or running out of gas. This enhances both safety and operational efficiency in gas management systems.

● Remote Monitoring and Alerts:

Propane Tank Gauge Monitor Ceramic PCBs work seamlessly with remote monitoring systems, offering real-time access to liquid level data. This feature is especially useful in large-scale LPG distribution networks where multiple tanks need to be monitored simultaneously. Alerts are triggered when a tank reaches a critical level, reducing the need for manual inspections and ensuring safe and efficient gas tank operation.

Design Considerations of LP Gas Tank Gauge Ceramic PCB :

LP Gas Tank Gauge Sender Ceramic PCBs are designed with careful consideration of material properties, electrical characteristics, environmental durability, and safety factors. These PCBs typically integrate sensors, often resistive or capacitive, to detect the liquid gas level inside a tank. LP Gas Tank Gauge Sender Ceramic PCBs offer distinct advantages over traditional FR4 or metal-core PCBs, especially in harsh conditions.

1. Material Selection and Properties of Ceramic PCBs:

Ceramic PCBs are chosen for their excellent thermal conductivity, stability under high temperatures, and mechanical robustness. These properties make them ideal for use in environments where the PCB will be exposed to high heat, pressure, or vibration, as is often the case with LP gas tanks.

● Thermal Conductivity: Ceramic materials (like alumina or aluminum nitride) have high thermal conductivity, which is crucial in dissipating heat generated during the operation of sensors or other components in the gauge.

● Mechanical Strength: Ceramics are mechanically stronger than typical fiberglass-based PCBs and are resistant to deformation under stress, which makes them a good choice for industrial applications where durability is key.

● Low Expansion Coefficient: Ceramics generally have low thermal expansion, which helps prevent the PCB from warping or cracking when subjected to temperature fluctuations, a common occurrence in outdoor environments where LP gas tanks are used.

● Electrical Insulation: Ceramic PCBs provide excellent electrical insulation, which is important for the reliability of sensor components in the gauge, especially in wet or chemically harsh environments.

2. Environmental Considerations:

LP gas tank gauges need to be able to function reliably under a wide range of environmental conditions, from extreme heat to cold, high humidity, and exposure to various chemicals. This makes environmental robustness a critical factor in PCB design.

● Corrosion Resistance: Ceramic materials are naturally resistant to corrosion, which is important when exposed to propane, butane, and other chemicals present in LP gas.

● Water and Dust Proofing: In many cases, the gas tank may be located outdoors or in humid conditions. Therefore, the PCB and sensors need to be resistant to moisture, dust, and other environmental contaminants. Proper sealing of the sensor components and PCB is essential.

● UV Resistance: In outdoor applications, ceramic PCBs offer better resistance to UV degradation than plastic-based PCBs.

● High-Temperature Tolerance: LP gas tanks, particularly in warmer climates or areas with fluctuating outdoor temperatures, can experience high temperatures. Ceramic PCBs, being able to withstand higher temperatures (often up to 300°C or more), are ideal for these conditions.

3. Sensor Integration with Ceramic PCB:

Most LP gas tank gauges incorporate sensors such as resistive sensors, capacitive sensors, or ultrasonic sensors to detect the liquid gas level. Ceramic PCBs can be used effectively to integrate these sensors in several ways:

● Resistive Sensors: A common type of sensor in liquid level detection is the resistive sensor. A float-based resistive sensor changes its resistance based on the liquid level inside the tank. A ceramic substrate can be used to house the resistive elements, providing robust mechanical support and better heat dissipation.

● Capacitive Sensors: In capacitive liquid level sensors, the liquid's dielectric constant changes based on its level inside the tank. Ceramic materials with low dielectric losses are ideal for these sensors, as they help maintain the accuracy and sensitivity of the measurements.

● Ultrasonic Sensors: These sensors use sound waves to determine the level of liquid inside the tank. Ceramic is commonly used for the piezoelectric element of ultrasonic sensors due to its excellent piezoelectric properties, enabling the conversion of mechanical stress into electrical signals with high precision.

4. Electrical Performance:

● Signal Integrity: Ceramic PCBs can maintain better signal integrity in high-frequency applications, which is important if the sensor systems involve RF communication or require high precision in the signal measurement and transmission.

● Impedance Matching: Ceramic substrates can be used to achieve precise control over signal impedance in sensors, helping improve the overall performance of the gas level gauge.

5. Safety Features:

Given the safety concerns associated with LP gas (flammable and potentially hazardous under certain conditions), the gauge design must include certain safety features to ensure that the ceramic PCB performs reliably without failure.

● Overvoltage Protection: LP gas tank gauges may need to interface with control systems that include high-voltage components. The ceramic PCB design must incorporate appropriate overvoltage protection mechanisms, such as Zener diodes or TVS diodes, to protect the sensitive components of the gauge.

● Short-Circuit Protection: Short circuits can lead to sensor failure or even fire hazards, so the PCB design must include short-circuit protection to ensure the gauge operates safely.

● Alarm and Fail-Safe Mechanisms: The design should include the ability to trigger alarms or system shutdowns in case of gauge or sensor failure, ensuring that the user is alerted before a critical safety situation arises.

6. Integration with IoT and Communication Systems:

Modern LP gas tank gauges may need to provide remote monitoring capabilities, enabling users to track gas levels via smartphones, web interfaces, or cloud-based systems. Integration with wireless communication systems like Wi-Fi, Bluetooth, or Zigbee can be achieved through onboard communication modules that interface with the ceramic PCB.

● Wireless Communication: When implementing wireless communication, signal integrity is critical, and ceramic PCBs’ excellent electrical properties can help optimize this aspect.

● Low Power Consumption: In applications requiring battery-powered wireless LP gas gauges, ceramic PCBs help minimize power consumption by supporting energy-efficient components.

LP Gas Tank Gauge Sender Ceramic PCBs are designed by selecting the appropriate materials, integrating sensors effectively, and ensuring the system can withstand harsh environmental conditions. LP Gas Tank Gauge Sender Ceramic PCBs offer high mechanical strength, excellent thermal management, and robust electrical insulation, making them ideal for use in gas tank level gauges where durability, accuracy, and safety are paramount. With proper attention to cost, performance, safety, and manufacturability, LP Gas Tank Gauge Ceramic PCBs can significantly enhance the reliability and functionality of LP gas tank gauges.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB