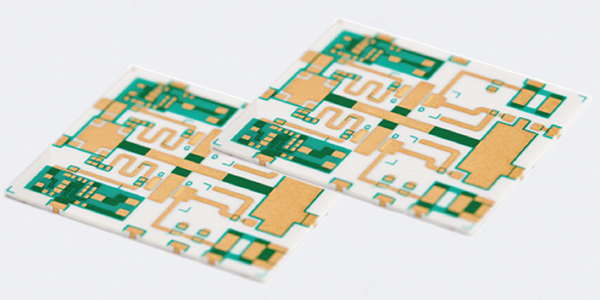

Gold Coated Thick Film Substrates

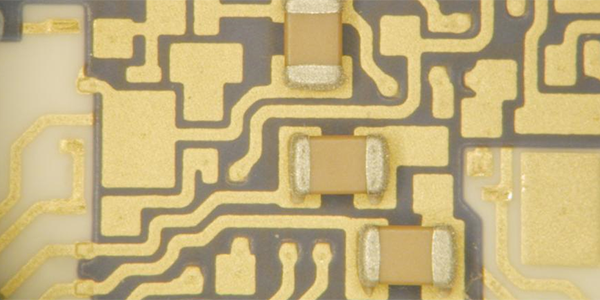

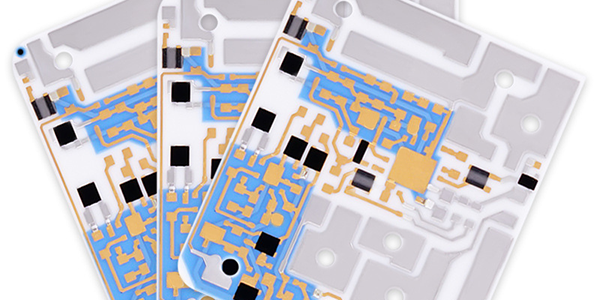

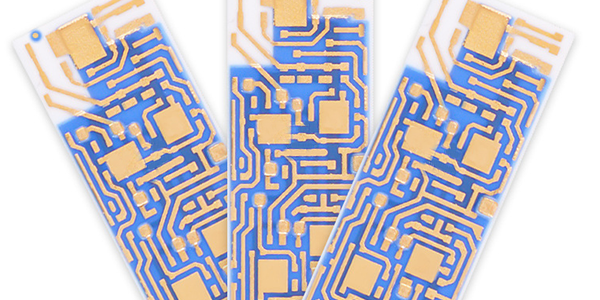

Gold Coated Thick Film Substrates, also called Thick Film Gold Coated Substrates, are advanced materials created through thick film circuit technology where gold paste is screen printed onto a ceramic substrate and then consolidated by a high-temperature sintering process, forming a conductive body that serves as the foundation for printed circuit boards and combining the benefits of gold's conductivity with the stability of ceramic materials to create a highly reliable electronic component.

Gold Coated Thick Film Substrates offer a combination of excellent electrical conductivity, high temperature resistance, and mechanical stability. The use of gold enhances the substrate's performance in electrical applications by ensuring efficient signal transmission and low resistance. Additionally, the ceramic base provides durability and thermal management, making these substrates suitable for use in harsh environments. The high-temperature sintering process ensures a strong bond between the gold and ceramic, resulting in long-lasting, high-performance substrates.

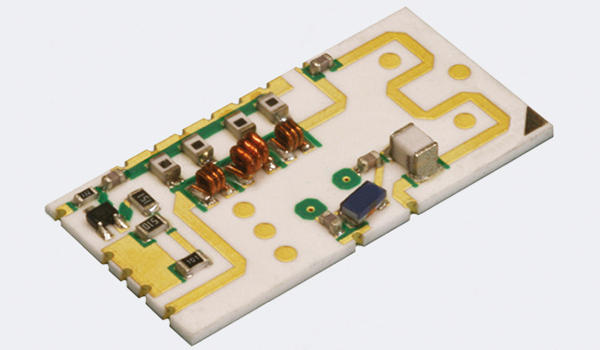

Thick Film Gold Coated Substrates are widely used in industries that require reliable and high-performance electronic circuitry, including telecommunications, aerospace, automotive, and medical fields. They are particularly valuable in applications such as power electronics, RF (radio frequency) devices, and high-frequency circuits where efficient conductivity and thermal management are essential. Ongoing advancements in thick film technologies continue to expand their use, driving innovation in next-generation electronics and opening up new areas for application in various high-tech industries.

Processes of Gold Coated Thick Film Substrates :

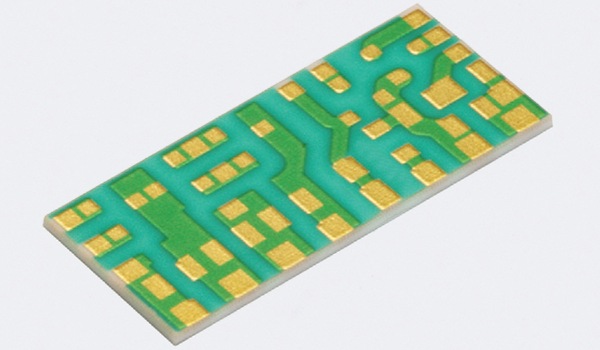

● Gold Paste Printing: Gold paste is evenly screen printed onto a ceramic substrate, commonly aluminum oxide or similar materials. The gold paste must be applied uniformly and adhere firmly to the ceramic surface, laying the foundation for subsequent processes.

● High-Temperature Sintering: The substrate undergoes a high-temperature sintering process, typically at 800–1000°C, where the gold particles bond tightly with the ceramic substrate, forming a durable conductive layer. This sintering process enhances both the electrical conductivity and the mechanical strength of the substrate, making it more reliable for high-performance applications.

● Fine Refining: After sintering, the substrate undergoes laser trimming or other precision processing methods to adjust its dimensions and ensure the gold layer's thickness is uniform and meets application requirements. This final step ensures that the gold-coated substrate is high-performance and precise, suitable for demanding electronic applications.

Features of Gold Coated Thick Film Substrates :

● Excellent Electrical Conductivity: Gold coating provides exceptional electrical conductivity, ensuring efficient signal transmission and low electrical resistance. This makes gold-coated thick film substrates ideal for applications requiring high-performance and reliable electrical connections.

● Thermal Stability and Resistance: Gold-coated thick film substrates exhibit excellent thermal stability. The combination of ceramic and gold ensures that these substrates can withstand high temperatures and thermal cycling, making them suitable for harsh environments and applications where heat management is critical.

● Mechanical Strength and Durability: The ceramic substrate, combined with the gold coating, offers outstanding mechanical strength and durability. The sintering process ensures a strong bond between the gold and ceramic, providing enhanced resistance to wear, vibration, and other mechanical stresses.

● Precision and Uniformity: Gold Coated Thick Film Substrates are produced with high precision, ensuring uniform thickness and smooth surface quality. The accuracy of the screen printing and sintering process guarantees consistent performance and reliability across all substrates.

● Versatility in Application: Gold Coated Thick Film Substrates can be used in a wide range of electronic applications, including power electronics, RF devices, high-frequency circuits, and other high-tech industries. Their ability to meet strict performance standards makes them versatile and adaptable to various specialized fields.

● Long Lifespan: The robust combination of gold and ceramic ensures a long lifespan for these substrates, even in demanding environments. The materials used are resistant to corrosion and degradation, ensuring that the substrates maintain their performance over time.

Applications of Gold Coated Thick Film Substrates :

● Telecommunications: Gold Coated Thick Film Substrates are widely used in telecommunications equipment, where their excellent electrical conductivity and thermal stability make them ideal for high-frequency circuits and power electronics. They ensure reliable performance in devices like signal processors, amplifiers, and transmitters.

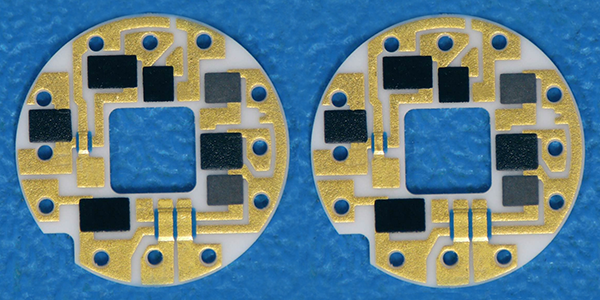

● Aerospace and Defense: The substrates are critical in aerospace and defense industries, where components must withstand extreme conditions. Their durability, resistance to high temperatures, and ability to maintain performance in harsh environments make them essential for aerospace electronics, satellite systems, and military applications.

● Automotive Electronics: In the automotive sector, gold-coated thick film substrates are used in advanced electronics such as sensors, power modules, and engine control units. Their mechanical strength and resistance to thermal cycling ensure long-term reliability in vehicles operating in diverse climates and conditions.

● Medical Devices: In the medical industry, these substrates are utilized in medical devices that require high reliability and performance. Their precise electrical conductivity and durability are crucial in devices such as implantable medical devices, diagnostic equipment, and surgical instruments.

● High-Frequency Circuits: Gold-coated thick film substrates are commonly employed in high-frequency circuits, where low resistance and efficient signal transmission are critical. These include RF circuits, microwave components, and communication systems that demand both thermal management and superior electrical conductivity.

● Power Electronics: Power electronics, especially in applications such as power supplies, converters, and inverters, benefit from the thermal stability and conductivity of these substrates. Their robust performance under high current and voltage conditions makes them an ideal choice for power management systems in various industries.

Military Applications of Thick Film Gold Coated Substrates :

Thick Film Gold Coated Substrates are utilized in military applications for their unique combination of electrical and thermal properties, as well as their reliability and performance in harsh environments. Here are some specific applications and considerations for their use in military products:

● High-Performance Electronics: Given the high conductivity and durability of gold, these substrates are ideal for use in high-reliability electronics within military communication systems, radar systems, and electronic warfare equipment, where consistent performance is critical.

● RF and Microwave Applications: The excellent electrical properties of gold make it suitable for radio frequency (RF) and microwave circuits used in military communication systems, where signal integrity and low loss are paramount.

● EMI/RFI Shielding: Gold's high electrical conductivity allows it to be used in electromagnetic interference (EMI) and radio frequency interference (RFI) shielding applications, protecting sensitive military electronics from external noise and ensuring the integrity of their operation.

● Harsh Environments: The thermal and mechanical stability of gold-coated substrates make them suitable for applications in extreme temperature and pressure conditions, such as those encountered in aerospace and naval operations.

● Optical Components: The optical properties of gold can be leveraged in military applications requiring precise optical coatings for components like lenses, filters, and waveguides, which are used in laser systems for target designation and rangefinding.

● Interconnects: In high-density packaging of military electronics, gold-coated thick film substrates can serve as interconnects, providing a low-resistance path for electrical signals while withstanding the mechanical and thermal stresses of the environment.

● Plasmonic Devices: Ultra-thin gold films have been shown to enhance terahertz conductivity when deposited onto specific substrates, which is beneficial for the development of advanced plasmonic and nano-photonic devices used in military surveillance and communication systems.

● Additive Manufacturing: With the advent of new techniques like microsputtering, additive manufacturing of gold thin films has become possible, offering a new approach to fabricating conductive patterns directly onto arbitrary substrates, which could be advantageous for rapid prototyping and customization in military applications.

These applications highlight the versatility and importance of Thick Film Gold Coated Substrates in the military sector, where their unique properties contribute to the performance and reliability of critical systems.

For more information, Please refer to Thick Film Substrates.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB