Thick Film Edible Oil Quality Sensors

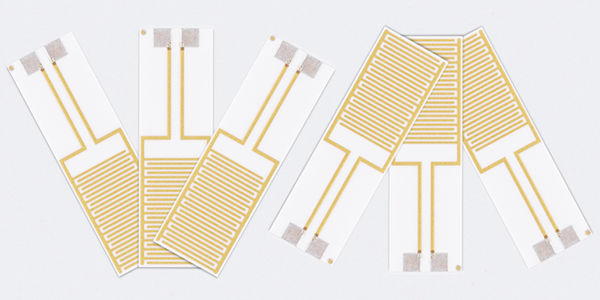

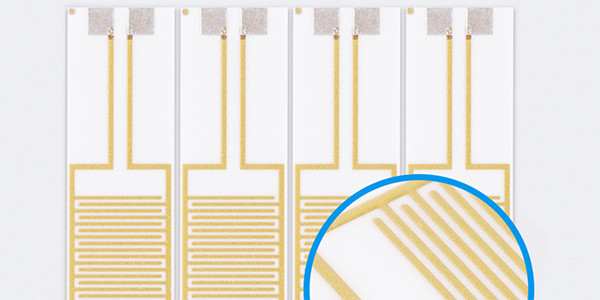

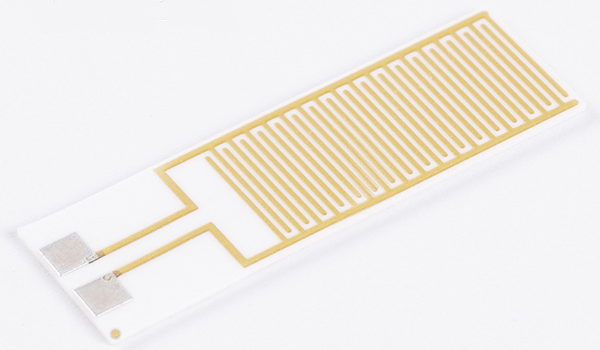

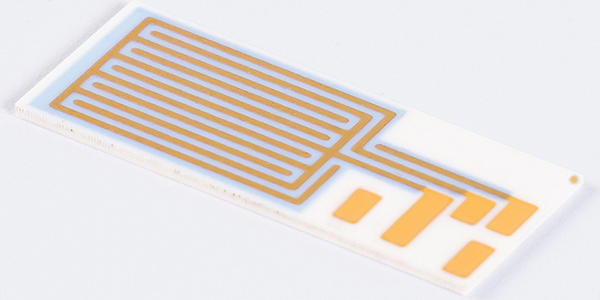

Thick Film Edible Oil Quality Sensors, also called Edible Oil Quality Thick Film Sensors, are specialized oil quality detection elements made by applying thick-film materials onto ceramic substrates and bonding conductive and sensing materials through high-temperature sintering, with an interdigital electrode design that enhances response speed and sensitivity, ensuring exceptional stability and anti-interference capabilities for reliable operation in high-temperature, high-pressure, and complex environments, demonstrating outstanding durability.

Thick Film Edible Oil Quality Sensors operate based on electrochemical principles and changes in electrical conductivity. When the sensor comes into contact with edible oil, the chemical composition of the oil affects its conductivity. The interdigital electrode measures the changes in current, reflecting the quality of the oil. The sensor can monitor key indicators such as contaminants, acidity, and aging of the oil, accurately determining the oil's condition and converting this information into an electrical signal for further analysis and processing by external devices. This design not only improves the accuracy of measurements but also ensures stable performance in complex operating environments.

Thick Film Edible Oil Quality Sensors are widely used in edible oil quality detection and monitoring, particularly in industrial production, the food service industry, and home kitchens. In the food service industry, they help businesses quickly assess the state of oil usage, preventing health risks associated with overused oil. In food processing plants, these sensors can monitor the repeated use of oil, reduce waste, and improve production efficiency. Additionally, with the development of smart kitchens and home appliances, Thick Film Edible Oil Quality Sensors have also been incorporated into smart range hoods, smart frying pans, and other household devices, enhancing the level of intelligence in these appliances.

Features of Thick Film Edible Oil Quality Sensors :

● High stability and durability: Thick Film Edible Oil Quality Sensors use ceramic substrates and thick-film technology, providing excellent stability. The material properties make the sensor resistant to temperature, humidity, and chemical influences, allowing it to work continuously in harsh environments.

● Strong anti-interference ability: The thick-film process of the sensor effectively suppresses external electromagnetic interference, ensuring the accuracy of its measurement signals. This allows the sensor to maintain stable performance in complex environments, especially under high temperature, high pressure, or other industrial conditions.

● High sensitivity and rapid response: Using interdigital electrode technology, Thick Film Edible Oil Quality Sensors can quickly respond to changes in the oil's conductivity, detecting variations in pollutants, acidity, and other parameters in real-time. This structural design enhances the sensor's response speed and sensitivity, ensuring fast and accurate quality detection.

● Long-term stable operation: Due to the high-temperature sintering process that fixes the sensing material, the sensor maintains stable performance even after long-term use, making it adaptable to various complex operating environments such as high temperature, acidity, alkalinity, and pressure.

● Precise monitoring of oil quality: The sensor can not only detect basic oil quality but also monitor pollutants, acidity, and aging levels, helping to accurately assess the oil's condition. This precise monitoring ability makes it widely used in the food processing and catering industries.

● Intelligent and convenient: With the development of smart home devices, Edible Oil Quality Thick Film Sensors can be integrated with intelligent kitchen equipment (such as smart range hoods and smart frying pans) to achieve real-time monitoring of oil quality, providing feedback and usage suggestions via intelligent systems, thereby enhancing the intelligence of the kitchen.

Thick Film Edible Oil Quality Sensors possess excellent characteristics such as high accuracy, long lifespan, and anti-interference, making them important tools in oil quality detection and oil monitoring.

For more information, Please refer to Thick Film Sensors.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB