Motorcycle Fuel Level Sensor PCB

Motorcycle Fuel Level Sensor PCBs, also called Motorcycle Fuel Level Sensor Ceramic PCBs, are specialized electronic components designed to monitor and report the fuel level within a motorcycle's fuel tank as an essential part of the motorcycle's fuel management system, providing real-time data on fuel levels to ensure the safe and efficient operation of the vehicle by accurately measuring the fuel in the tank, allowing the rider to monitor the fuel status at all times, preventing unexpected fuel shortages and helping optimize fuel efficiency.

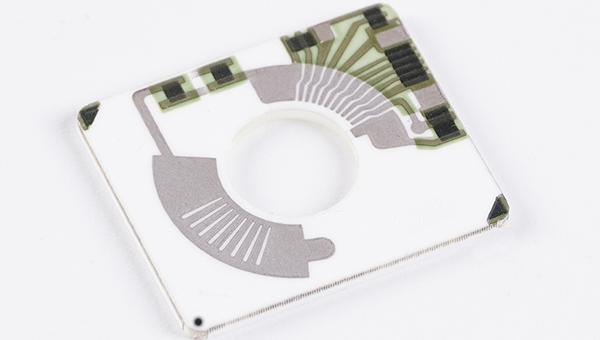

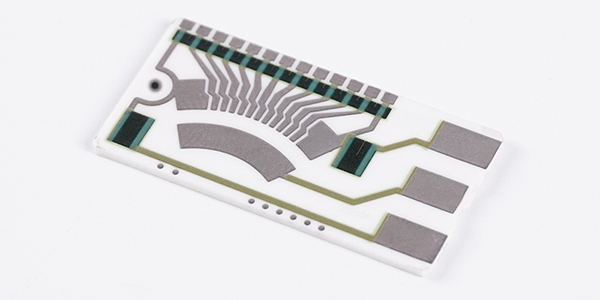

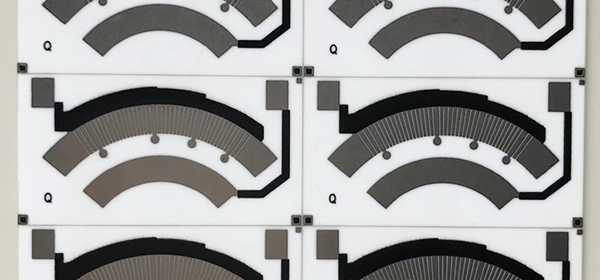

Motorcycle Fuel Level Sensor PCBs are produced using thick-film resistor technology in combination with a ceramic substrate. This manufacturing method involves applying a resistive material onto the ceramic base through thick-film printing techniques. The ceramic substrate is chosen for its excellent thermal conductivity, high mechanical strength, and resistance to high temperatures, ensuring the component’s reliability under harsh conditions. The precision of the thick-film process allows for exact resistance values, guaranteeing accurate fuel level readings.

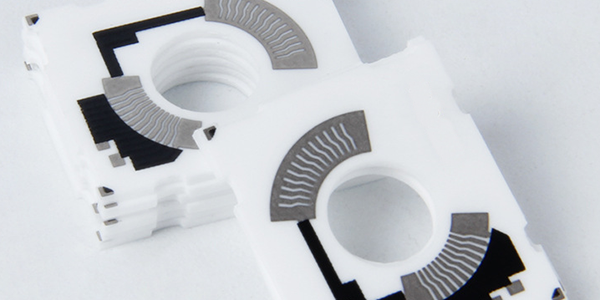

Motorcycle Fuel Level Sensor Ceramic PCBs are characterized by their high accuracy and long-term stability in measuring fuel levels. The ceramic material provides exceptional thermal stability and high-temperature resistance, making it well-suited for the demanding operating environments found in motorcycles. The use of thick-film technology further enhances the durability and lifespan of the component, ensuring reliable performance over time. Additionally, the compact design of these PCBs makes them easy to integrate into the motorcycle's fuel system without compromising space or functionality.

Motorcycle Fuel Level Sensor Ceramic PCBs are primarily used in motorcycles as a crucial part of the fuel management system. They deliver precise fuel level information to the motorcycle's dashboard or digital display, allowing riders to monitor fuel consumption and avoid running out of fuel. These PCBs are also suitable for other two-wheeled vehicles that require accurate fuel level monitoring, and in high-performance vehicles where precise fuel measurement is vital for engine optimization. The ceramic-based design also makes them ideal for other applications that demand high-temperature resistance and precise measurements.

Features of Motorcycle Fuel Level Sensor PCB :

● Functionality: The primary function of the Motorcycle Fuel Level Sensor PCBs are to measure the volume of fuel in the tank and convert this measurement into an electrical signal. This signal is then sent to the motorcycle's dashboard or digital display, where it is interpreted and shown as a fuel gauge reading.

● Design: Typically, this Motorcycle Fuel Level Sensor PCB is housed within a fuel tank and contains a float mechanism. The float moves up and down with the fuel level, and its position is directly proportional to the fuel level in the tank. This movement is detected by a potentiometer or a similar variable resistor integrated into the PCB.

● Technology: Motorcycle Fuel Level Sensor PCB utilizes thick film sensor technology, which is a method of creating electronic circuits by printing thin layers of conductive material onto an insulating substrate. This technology allows for the creation of compact, durable, and precise electronic components that can withstand the harsh conditions inside a fuel tank.

● Materials: Motorcycle Fuel Level Sensor PCBs are made from materials (Ceramic substrate, Ag/Pd conductor, Carbon resistive film) that are resistant to fuel, heat, and other environmental factors commonly found in a motorcycle's fuel system. This ensures that the PCB remains functional and accurate over time, even under challenging conditions.

● Integration: Motorcycle Fuel Level Sensor PCBs are designed to be easily integrated into a wide range of motorcycle models. Its compatibility with various fuel tank designs and electronic systems makes it a versatile component in the motorcycle industry.

● Safety: By providing accurate fuel level readings, this PCB helps prevent overfueling, which can lead to dangerous situations such as fuel leaks or engine damage. It also alerts riders when their fuel is running low, preventing them from running out of fuel unexpectedly.

● Low Maintenance: Due to its solid-state design, the Motorcycle Fuel Level Sensor PCB requires minimal maintenance. This reduces the overall cost of ownership and ensures that the component remains reliable and accurate throughout its service life.

● High Accuracy: Utilizing advanced thick film technology, the Motorcycle Fuel Level Sensor PCB provides precise measurements of fuel levels, ensuring that the fuel gauge on the motorcycle's dashboard is always accurate.

● Durability: Constructed with robust materials, this Motorcycle Fuel Level Sensor PCB is designed to withstand the rigors of motorcycle use, including vibrations, temperature fluctuations, and exposure to fuel.

● Compatibility: Compatible with a wide range of motorcycle models, the Fuel Level Sender PCB can be easily integrated into various fuel tank designs without significant modifications.

● Easy Installation: The design of the Motorcycle Fuel Level Sensor PCB facilitates straightforward installation, minimizing the time and complexity involved in retrofitting or replacing the sensor.

In essence, the Motorcycle Fuel Level Sensor PCB is a critical safety and convenience feature in motorcycles, ensuring that riders have accurate and reliable information about their fuel status at all times.

Advantages of Motorcycle Fuel Level Sensor PCB :

● Enhanced Safety: By providing accurate fuel level readings, the Motorcycle Fuel Level Sensor PCB helps prevent overfueling or running the motorcycle on empty, which can be dangerous.

● Improved Fuel Efficiency: Riders can better manage their fuel consumption with precise fuel level information, potentially extending the distance they can travel between refueling.

● Reliability: The use of thick film technology in the PCB ensures a reliable performance over time, reducing the likelihood of sensor failure.

● Cost-Effective: While providing high-quality performance, the Motorcycle Fuel Level Sender Ceramic PCB is also a cost-effective solution compared to other fuel level sensing technologies.

● Environmental Friendliness: The solid-state design of the PCB reduces the need for regular maintenance, thereby minimizing environmental impact through reduced waste.

How Motorcycle Fuel Level Sensor PCB Works ?

Motorcycle Fuel Level Sensor PCBs operate by using a float mechanism that moves up and down with the fuel level in the tank. This movement is translated into an electrical signal via a variable resistor (potentiometer) integrated into the PCB. As the float rises or falls, the resistance changes, which is then converted into a voltage signal. This signal is sent to the motorcycle's dashboard or digital display, where it is interpreted and displayed as the current fuel level. The process can be broken down into the following steps:

● Float Movement: The float inside the fuel tank moves with the changing fuel level.

● Resistance Change: The movement of the float alters the resistance in the potentiometer on the PCB.

● Signal Conversion: The change in resistance is converted into a voltage signal proportional to the fuel level.

● Signal Transmission: The voltage signal is transmitted to the motorcycle's dashboard or digital display.

● Display Interpretation: The display interprets the signal and shows the current fuel level to the rider.

Substrates of Motorcycle Fuel Level Sensor Ceramic PCB :

The use of ceramic substrates in Motorcycle Fuel Level Sensor Ceramic PCBs offers several advantages that make them an ideal choice for this application. Here's why ceramic substrates are preferred:

● High Thermal Conductivity: Ceramic substrates, such as those made from aluminum oxide (Al2O3) or aluminum nitride (AlN), have excellent thermal conductivity. This property allows for efficient heat dissipation, which is crucial in applications where components generate heat, such as in fuel sensors. For example, Al2O3 has a thermal conductivity that is significantly higher than that of FR-4, a common material used in traditional PCBs .

● Electrical Insulation: Ceramic materials provide excellent electrical insulation, which is essential for the safe operation of electronic components in a fuel sensor. This insulation helps prevent electrical shorts and ensures the reliability of the sensor in various operating conditions .

● Chemical Resistance: Ceramic substrates are highly resistant to chemicals, including fuels like gasoline and diesel. This resistance prevents the substrate from being degraded by the fuel, ensuring the long-term stability and accuracy of the sensor .

● Mechanical Strength: Ceramic materials have high mechanical strength, making them durable and resistant to mechanical stress. This is particularly important in applications like motorcycle fuel sensors, where the PCB may be subjected to vibrations and impacts .

● Low Dielectric Constant: The low dielectric constant of ceramic substrates helps in reducing signal loss and improving the speed of signal transmission. This is beneficial in high-frequency applications, ensuring that the sensor provides accurate and timely readings .

● Thermal Stability: Ceramic substrates have a low thermal expansion coefficient, which means they do not expand or contract significantly with temperature changes. This property is crucial for maintaining the accuracy of the sensor in varying environmental conditions .

● High-Temperature Operation: Ceramic substrates can withstand high temperatures, making them suitable for use in environments where traditional PCB materials might fail. This is particularly important in automotive applications, where components may be exposed to high temperatures .

● Environmental Stability: Ceramic substrates are resistant to moisture and other environmental factors, ensuring that the sensor remains functional even in harsh conditions. This stability is crucial for the reliability of the fuel level sensor in various weather conditions .

● Long Service Life: Due to their durability and resistance to various environmental factors, ceramic substrates offer a longer service life compared to traditional PCB materials. This reduces the need for frequent replacements and maintenance, making them a cost-effective choice in the long run .

The use of ceramic substrates in Motorcycle Fuel Level Sensor Ceramic PCBs provides a combination of high thermal conductivity, electrical insulation, chemical resistance, mechanical strength, low dielectric constant, thermal stability, and high-temperature operation. These properties make ceramic substrates an ideal choice for applications requiring high reliability and performance in challenging environments.

Designing of Motorcycle Fuel Level Sensor Ceramic PCB :

Designing a Motorcycle Fuel Level Sensor Ceramic PCB requires careful consideration of various factors to ensure accuracy, reliability, and longevity. Here are some design considerations for engineers working on such a project:

● Thick Film Technology: Utilize thick film hybrid circuits fired on an alumina substrate (Ceramic) for their chemical stability and resistance to the harsh environment found in fuel tanks .

● Conductive Paste Composition: When using silver-palladium (Ag-Pd) conductive thick film ink, ensure a minimum 25% palladium level to reduce smearing and increase tarnish resistance .

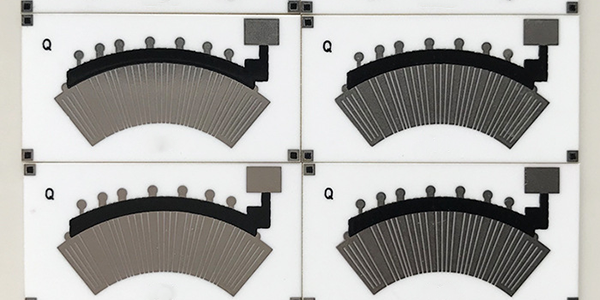

● Circuit Layout: Opt for dual trace circuit patterns as they allow for noble metals at all sliding interfaces, which is beneficial for durability and signal integrity .

● Contact Material Hardness: The sliding contact material should have a minimum hardness of 300 Hk to resist abrasive wear from the inks .

● Noise Reduction: Address noise-related problems by using materials that produce thinner sulfide films, which require less contact abrasion for cleaning, thus allowing for lower gram forces and reduced wear debris .

● Contact Material (Wiper or Rivet): Paliney 6 has shown the highest resistance to sulfide film formation among tested contact materials and is recommended for use .

● Multi-Fingered Contact Design: Implementing multi-fingered (bifurcated) contact designs reduces sensitivity to surface films and allows for the use of reduced gram forces .

● Voltage Divider Configuration: For variable resistance sensors, create a voltage divider by connecting one end of the variable resistor to the positive supply, the wiper to the signal input of the gauge, and the other end to ground. Use a fixed resistor in conjunction with the variable resistor to complete the divider .

● Resistor Selection: If using a potentiometer as a variable resistor, ensure it is part of a voltage divider configuration, with the wiper connected to the signal input of the gauge and the ends connected to the supply and ground .

● Environmental Considerations: Design the PCB to be resistant to the chemicals found in fuel and capable of withstanding the temperature fluctuations and mechanical stresses typical in a motorcycle's operating environment.

By adhering to these guidelines, engineers can develop a Motorcycle Fuel Level Sensor PCB that is not only accurate and reliable but also capable of withstanding the harsh conditions it will encounter in use.

For more information, Please refer to Thick Film Sensors.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB