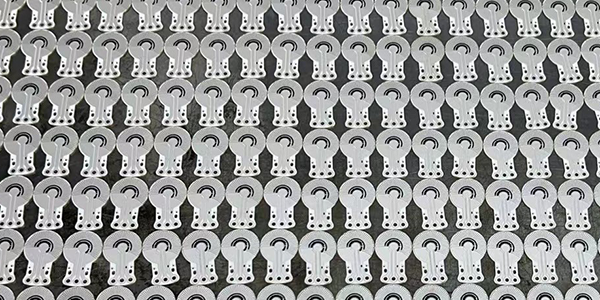

Remote Ready Sender Ceramic PCB

Remote Ready Sender Ceramic PCBs, also called Remote Ready Dial Ceramic PCBs, are specialized components designed for remote monitoring of liquid levels in LPG (Liquefied Petroleum Gas) tanks, operating on the principle of resistance variation, where the PCB's resistance changes in response to fluctuating liquid or gas levels, with these changes converted into electrical signals that are transmitted to a central control system or remote receiver, enabling continuous monitoring, alarm generation, and integration with automation control systems, providing precise and reliable liquid level measurements while enhancing both safety and operational efficiency.

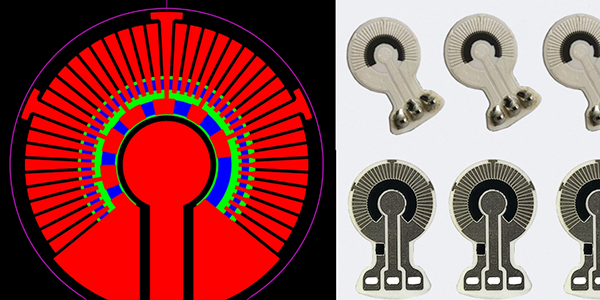

Remote Ready Sender Ceramic PCBs are produced using thick-film hybrid circuit technology. The process involves screen-printing conductive and resistive paste onto a ceramic substrate, which is then sintered to create a durable and high-performance circuit board. This manufacturing technique ensures that the PCB has variable resistance properties that change with external conditions, such as liquid level variations. The use of ceramic substrates guarantees the PCB’s high temperature resistance, corrosion resistance, and long-term stability, making it suitable for use in demanding industrial environments.

Remote Ready Dial Ceramic PCBs are characterized by their exceptional mechanical strength, excellent thermal management, and reliable electrical insulation. Their ceramic construction ensures they are resistant to high temperatures and corrosion, providing long-lasting performance in harsh environments. The variable resistance characteristics of the PCB enable precise detection of liquid level changes, while their remote transmission capabilities allow for real-time monitoring without direct interaction with the tank. These features enhance both safety and convenience for users in industrial applications.

Remote Ready Gauge Ceramic PCBs are widely used in industries where remote liquid level monitoring is essential, such as petroleum, chemical, agriculture, and industrial fuel storage sectors. They are commonly integrated into LP Gas Tank Gauges, Liquid Level Sensors, and other monitoring systems. These PCBs are critical in applications requiring continuous monitoring, early warning alerts, and data transmission to prevent malfunctions or safety hazards. Their ability to remotely monitor multiple tanks simultaneously makes them ideal for large-scale automated systems, ensuring optimal performance and safety in diverse industrial settings.

Working Principle of Remote Ready Sender Ceramic PCB :

Remote Ready Sender Ceramic PCBs work based on the principle of resistance variation in response to changes in the liquid or gas level inside a tank. Here's a breakdown of how it operates:

● Resistance-Based Sensor:

Remote Ready Sender Ceramic PCB integrates a resistance sensor that is sensitive to changes in the liquid or gas level. The ceramic material used in the PCB is chosen for its durability and high resistance to environmental conditions such as heat, pressure, and chemical exposure.

● Liquid/Gas Level Change:

As the liquid or gas level inside the tank fluctuates, the contact between the liquid and the sensor changes. This results in a variation in the resistance of the PCB. For example, when the liquid level increases, the resistance decreases, and when the liquid level drops, the resistance increases.

● Signal Conversion:

The changes in resistance are then converted into an electrical signal. This signal corresponds to the level of the liquid or gas inside the tank. The resistance changes are accurately measured by the PCB’s circuit, ensuring precise data collection.

● Signal Transmission:

Once the resistance change is converted into an electrical signal, it is transmitted to a remote monitoring system or control unit. This enables continuous remote monitoring of the tank’s liquid or gas level without requiring direct interaction with the tank.

● Real-Time Monitoring and Alerts:

The transmitted data allows users to monitor the tank level in real-time, providing crucial information for inventory management, maintenance, and refueling schedules. If the liquid or gas level approaches critical thresholds (e.g., too high or too low), the system can trigger alarms or notifications, allowing users to take timely action.

This system is particularly effective in environments where remote monitoring is required, such as in LP Gas tanks, ensuring high accuracy, reliability, and safety in operations.

Features of Remote Ready Dial Ceramic PCB :

Remote Ready Dial Ceramic PCBs offer several key features that enhance its functionality and reliability in monitoring gas levels.

● Resistance-Based Sensing Technology: Remote Ready Dial Ceramic PCB uses a resistance-based sensor to detect changes in the gas or liquid level inside the LP gas tank, converting these changes into electrical signals for monitoring purposes.

● Remote Monitoring Capability: It allows for remote monitoring of gas tank levels, enabling users to check the current levels without needing to physically inspect the tanks, which adds convenience and safety.

● Real-Time Data Transmission: Remote Ready Dial Ceramic PCB continuously sends real-time data about the liquid or gas level to a central monitoring system or control unit, ensuring users are kept up-to-date on the status of the tank.

● Alarm and Alert Integration: It can be integrated with alarm systems that notify users when the gas levels approach critical thresholds, preventing risks such as running out of fuel, overpressure, or gas leaks.

● Durability and Reliability: Designed to withstand harsh environments, the Remote OHM Sender PCB is built to function reliably even in extreme temperatures and challenging conditions, ensuring long-term performance.

● Accuracy and Precision: The sensor provides highly accurate readings of the gas levels, ensuring that the monitoring system delivers reliable data for operational decision-making.

● Energy Efficiency: Many Remote Ready Dial Ceramic PCBs are designed with low power consumption in mind, allowing them to operate efficiently over extended periods, especially in remote or off-grid locations.

● Flexible Integration: The system can easily integrate with other monitoring and control systems, such as SCADA (Supervisory Control and Data Acquisition) or IoT platforms, for centralized control and automation.

● Compact and Lightweight: The design is often compact and lightweight, making it easy to install and integrate into existing LP gas tank infrastructure without taking up much space.

● Cost-Effectiveness: By reducing the need for manual inspections and enabling predictive maintenance, the system can reduce operational costs and increase safety, which is particularly beneficial for businesses that rely on large numbers of gas tanks.

These features make the Remote Ready Dial Ceramic PCB a crucial component in the modern management of LP Gas Tanks, ensuring both operational efficiency and safety.

Applications of Remote Ready Sender Ceramic PCB :

Remote Ready Sender Ceramic PCBs are used in various industries and applications where monitoring and managing gas levels remotely are essential. Some of the key applications include:

1. LP Gas Distribution and Storage:

● Tank Monitoring: Used in LP gas storage tanks and distribution systems, the Remote Ready Sender Ceramic PCB continuously monitors gas levels, ensuring timely refills and preventing disruptions in service.

● Safety Alerts: Triggers alarms or notifications when gas levels are dangerously low or if there is a risk of overpressure, helping prevent safety hazards such as leaks or tank rupture.

2. Industrial Applications:

● Manufacturing Plants: In factories where LP gas is used for heating or as an energy source, the Remote Ready Sender Ceramic PCBs help monitor tank levels to ensure consistent energy supply without interruptions.

● Chemical Plants: Used for monitoring gas supply levels in plants that rely on LP gas for various processes, ensuring smooth operations and safety.

3. Residential and Commercial LPG Supply:

● Home Heating Systems: In homes that use LP gas for heating, cooking, or hot water, Remote Ready Sender Ceramic PCBs provide real-time data to ensure that users are alerted when gas levels are low, reducing the risk of running out of fuel unexpectedly.

● Restaurants & Hotels: Establishments that rely on large volumes of gas for cooking and heating can use this system to monitor multiple tanks at once, optimizing usage and preventing outages.

4. Off-Grid Energy Systems:

● Remote Locations: For homes, businesses, or facilities located in remote areas without access to natural gas pipelines, Remote Ready Sender Ceramic PCBs help monitor LP gas levels, ensuring that fuel is available when needed and reducing unnecessary trips for manual inspections.

● Renewable Energy Backup: Used in hybrid systems where LP gas may be a backup energy source in conjunction with solar or wind power, allowing for efficient monitoring and usage management.

5. Transportation and Mobile Applications:

● RV and Marine Gas Tanks: In recreational vehicles (RVs), boats, and yachts that use LP gas for cooking, heating, or refrigeration, the Remote Ready Sender Ceramic PCB allows users to monitor their gas levels while on the move.

● Fleet Management: Used in the transportation sector for monitoring gas levels in delivery trucks or vehicles that rely on LP gas or autogas (LPG) as an alternative fuel.

6. Agricultural Applications:

● Greenhouses and Farms: Remote monitoring of LP gas used in heating systems for greenhouses or farm operations ensures efficient use of fuel and prevents the risk of running out of gas during critical times.

● Irrigation Systems: In rural or agricultural settings that use LP gas-powered irrigation pumps or other equipment, the PCB helps monitor fuel levels, minimizing downtime.

7. Oil & Gas Industry:

● Storage Facilities: In large-scale oil and gas storage facilities, Remote Ready Sender Ceramic PCBs are used to monitor LP gas or other fuels stored in tanks, enabling continuous inventory tracking and reducing the likelihood of stockouts or overflows.

● Safety and Compliance: Regular and accurate monitoring of gas levels is critical to comply with safety regulations and avoid risks associated with the volatile nature of LP gas.

8. Emergency Response and Disaster Relief:

● Mobile Gas Supplies: In disaster relief operations, where portable gas tanks are used for cooking, heating, or generating power, the system can ensure that tanks are properly managed and refilled as necessary.

● Temporary Camps or Shelters: For temporary shelters using LP gas for cooking and heating, the Remote Ready Gauge Ceramic PCB helps maintain a safe and consistent gas supply.

9. Automated Smart Homes and IoT Applications:

● Smart Home Integration: In smart homes, the system can be integrated with other IoT devices to automatically monitor and manage LP gas usage, alerting homeowners when they need to reorder or refill gas.

● Building Automation Systems: Used in commercial buildings to automate and optimize energy use, the system can be integrated into larger BAS for gas usage management.

10. Energy Management and Optimization Systems:

● Predictive Maintenance: In any setting where LP gas tanks are used, the Remote Ready Gauge Ceramic PCB can help identify patterns in gas consumption and predict when a tank will need refilling, reducing downtime and optimizing energy usage.

● Fleet Fueling Systems: Used in fleet fuel management systems where multiple gas tanks need to be monitored and managed efficiently.

11. Mining and Industrial Equipment:

● Remote Monitoring in Harsh Environments: In mining operations where LP gas is used for equipment fueling, the system helps monitor the gas levels of tanks in remote or hazardous locations, improving both safety and operational efficiency.

In all these applications, the Remote Ready Gauge Ceramic PCB plays a critical role in ensuring the safe, efficient, and cost-effective use of LP Gas, preventing potential hazards and ensuring a continuous supply when it's needed most.

For more information, Please refer to Thick Film Ceramic Resistors.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB