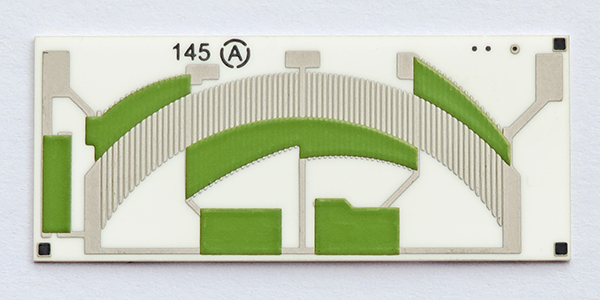

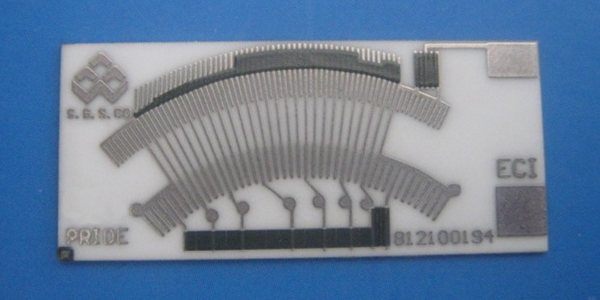

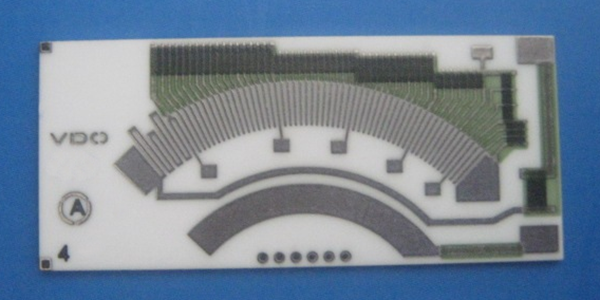

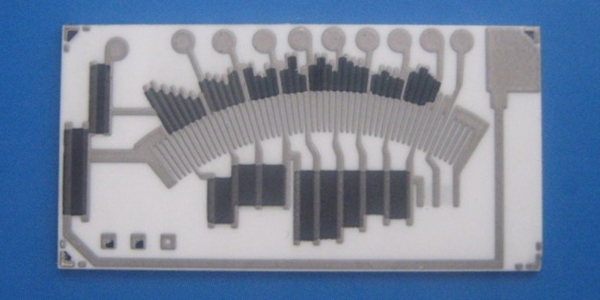

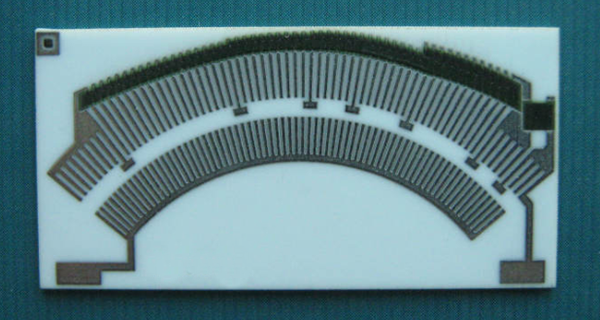

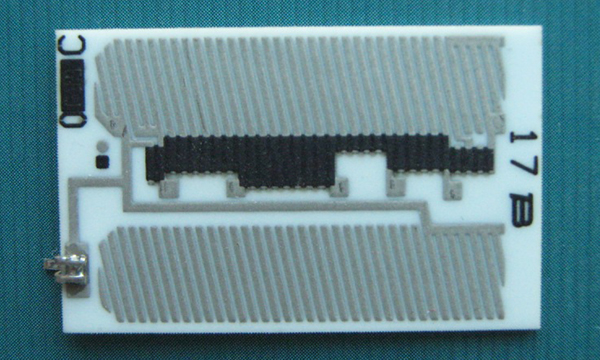

Oil Level Sensor Ceramic PCB

Oil Level Sensor Ceramic PCBs are specially designed circuit boards for the precise measurement and monitoring of oil levels, utilizing thick film hybrid technology combined with ceramic substrates to detect oil levels by monitoring the electrical performance changes between the ceramic substrate and oil, and are typically installed in fuel tanks to provide real-time oil level readings, ensuring the proper operation of vehicles and industrial equipment, especially in high-precision environments where safe and efficient operation is critical.

Oil Level Sensor Ceramic PCBs employ advanced thick film technology and ceramic substrates in their production, ensuring high stability and durability in extreme environments. The thick film process combines conductive materials with ceramic substrates to create circuits that are resistant to high temperatures and corrosion. The ceramic substrate also provides superior thermal stability and excellent electrical performance. This production process enables the oil level sensor ceramic PCBs to function reliably in extreme temperatures, pressures, and oil environments, making them ideal for challenging applications.

Oil Level Sensor Ceramic PCBs are known for their high durability, long lifespan, and precision. The ceramic substrate offers exceptional thermal stability and corrosion resistance, while the thick film technology ensures stable electrical performance. These sensors are essential in automotive, industrial, and aerospace applications, providing accurate oil level monitoring and contributing to the safe and efficient operation of machinery. Their compact design also makes them suitable for space-constrained environments, establishing them as key components in liquid level monitoring systems across various industries.

Oil Level Sensor Ceramic PCBs have broad applications across various industries, particularly in the automotive, machinery, and aerospace sectors. They are used to monitor oil levels, liquid levels, and other critical fluid changes, ensuring system reliability and performance. In demanding environments, the high precision, reliability, and durability of these sensors are essential for maintaining the proper function of complex systems. These sensors are found not only in conventional vehicles but also in military aviation, aerospace, and specialized industrial equipment, offering stable and reliable solutions for liquid level monitoring in a range of applications.

Features of Oil Level Sensor Ceramic PCB :

● High Durability: Ceramic PCBs are highly resistant to high temperatures, making them ideal for use in oil-level sensors, which operate in harsh environments.

● Compact Design: Oil Level Sensor Ceramic PCBs are thinner than traditional PCBs, allowing for smaller and more efficient sensor designs, perfect for tight spaces in machinery or vehicles.

● Electrical Insulation: Ceramic material provides excellent electrical insulation properties, ensuring safe operation and preventing short circuits in oil-level sensors.

● Thermal Conductivity: Oil Level Sensor Ceramic PCB offer superior thermal conductivity, ensuring the sensor performs well even in extreme temperatures, reducing the risk of overheating.

● Chemical Resistance: Oil Level Sensor Ceramic PCBs are resistant to chemicals, oils, and other harsh fluids, which makes them ideal for use in oil-level sensors that interact with different types of oils and liquids.

● High Precision: They provide high accuracy in sensing oil levels, making them crucial in industrial and automotive applications for reliable performance.

● Long Lifespan: Thanks to their resilience to wear and environmental stress, ceramic PCBs contribute to the sensor's long-term reliability.

Applications of Oil Level Sensor Ceramic PCB :

● Automotive Industry:

Ceramic PCBs are widely used in oil-level sensors for engines and transmissions. The high heat resistance and durability make them suitable for monitoring oil levels in automotive systems, ensuring optimal engine performance and preventing damage due to low oil levels.

● Industrial Machinery:

In industries such as manufacturing, energy production, and heavy machinery, Oil Level Sensor Ceramic PCBs are essential for monitoring lubrication systems. These sensors help ensure that equipment runs smoothly by detecting oil levels in compressors, pumps, turbines, and hydraulic systems.

● Aerospace and Aviation:

In aircraft, the precision and reliability of oil level sensors with ceramic PCBs are crucial for maintaining safe operations. These sensors monitor critical systems like engines and hydraulic fluid levels, preventing malfunction in high-pressure and temperature environments.

● Marine Applications:

Boats and ships, particularly in engines and gearboxes, utilize oil-level sensors with ceramic PCBs to track lubrication fluid levels. The sensors' resistance to corrosion and harsh marine conditions ensures the longevity of critical engine components.

● Oil and Gas Industry:

The oil and gas industry uses these sensors in drilling equipment and offshore platforms to monitor oil levels in various machinery. The robust nature of ceramic PCBs withstands the demanding environment of drilling rigs and refineries.

● Renewable Energy:

Wind turbines and solar power systems use oil-level sensors to monitor lubrication in their mechanical components. Oil Level Sensor Ceramic PCBs offer long-lasting performance in these systems where equipment uptime is critical.

● Heavy Equipment and Construction:

Oil level sensors with ceramic PCBs are crucial for heavy-duty construction machinery like excavators, bulldozers, and cranes. These sensors ensure the proper functioning of engines and hydraulic systems by detecting low oil levels, which could otherwise cause equipment failure.

● Medical Devices:

Some medical devices, such as diagnostic machines and pumps, use oil-level sensors to monitor the fluid levels of critical moving parts, ensuring precision and reliability in their operation.

● Power Generation:

Power plants that utilize generators, turbines, or hydraulic systems often incorporate oil-level sensors with ceramic PCBs to ensure smooth and reliable operations, minimizing the risk of equipment breakdowns.

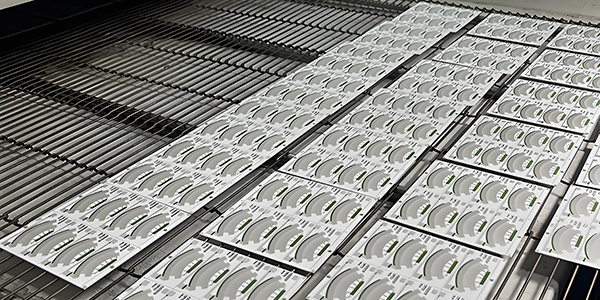

Manufacturing of Oil Level Sensor Ceramic PCB :

1. Substrate Preparation:

● Materials: The process begins with the preparation of a ceramic substrate, which forms the base of the PCB. The substrate is typically made from materials such as alumina or beryllia, chosen for their excellent thermal conductivity, electrical insulation, and chemical resistance. The ceramic material is cut to the required thickness and dimensions based on the design specifications.

● Surface Treatment: The substrate undergoes surface cleaning and conditioning to enhance the adhesion of the subsequent layers. This may include abrasive blasting or chemical etching to achieve the desired surface roughness.

2. Circuit Patterning:

● Screen Printing: Thick-film conductive pastes, usually silver, gold, or copper-based, are screen-printed onto the prepared ceramic substrate. This forms the electrical circuit pattern that will connect various components in the sensor. The pastes are precisely applied to create the necessary traces and pads for component placement.

● Design Precision: The circuit design is carefully crafted to meet the sensor’s functional requirements. This step demands high precision, as the integrity of the circuit directly influences the sensor’s performance.

3. Firing (High-Temperature Sintering):

● Sintering: The printed patterns are then fired in a high-temperature oven, typically between 850°C to 1000°C. This step allows the thick-film paste to fuse onto the ceramic surface, ensuring strong adhesion and conductivity. The firing process also ensures that the conductive layers are securely bonded to the ceramic substrate.

● Temperature Control: The firing process is meticulously controlled to ensure that the thick-film paste is cured uniformly, preventing any defects in the circuit patterns.

4. Sensing Element Integration:

● Component Integration: The sensing elements, such as resistors, capacitors, and thermistors, are integrated into the circuit. These components are crucial for the sensor’s functionality, as they help detect oil levels by responding to changes in electrical resistance or capacitance. The integration is done with precision, ensuring that each element is placed accurately to maintain sensor reliability.

● Advanced Materials: In some cases, specialized materials, such as piezoelectric or thermocouples, may be integrated depending on the type of oil level sensor being manufactured.

5. Assembly of Electronics:

● Component Placement: Once the circuit pattern and sensing elements are in place, additional electronic components like microchips, connectors, and leads are mounted onto the ceramic PCB. This step ensures that the sensor has the necessary interfaces to communicate with external systems or controllers.

● Soldering: The components are soldered using advanced soldering techniques to ensure a reliable and robust connection. In some cases, automated soldering machines are used for precision.

6. Encapsulation and Protection:

● Environmental Protection: The PCB may be encapsulated with a protective coating to shield it from environmental factors such as moisture, dust, or chemicals. This is especially important in industrial, automotive, and aerospace applications where sensors are exposed to harsh conditions.

● Hermetic Sealing: For critical applications, the sensor may undergo hermetic sealing to ensure that no contaminants affect the internal components, enhancing the sensor’s lifespan and reliability.

7. Testing and Calibration:

● Performance Testing: Each ceramic PCB sensor undergoes rigorous testing to verify its functionality. This includes checking the accuracy of oil level detection, electrical conductivity, and response time to ensure it meets specifications.

● Calibration: The sensor is calibrated to detect a range of oil levels with high precision. Calibration ensures that the sensor gives consistent and accurate readings under varying conditions, including temperature fluctuations.

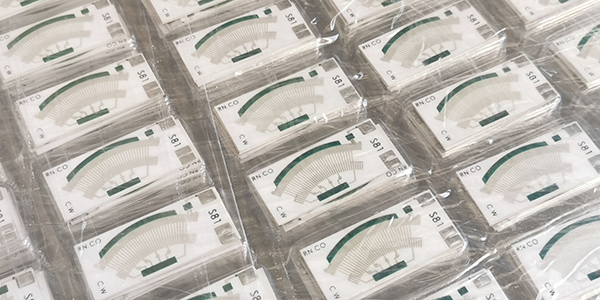

8. Final Inspection and Quality Control:

● Visual Inspection: The final product is thoroughly inspected for any visual defects, such as cracks, misaligned components, or irregular solder joints. Automated optical inspection (AOI) systems may be used for enhanced accuracy.

● Reliability Testing: The sensors undergo environmental testing, such as thermal cycling, vibration, and chemical exposure, to simulate the conditions in which they will operate. This helps ensure that the sensor will perform reliably under real-world conditions.

Specifications of Oil Level Sensor Ceramic PCB :

● Ceramic Substrate: Can be 96% or 98% Alumina (Al2O3), Aluminum Nitride, or Beryllium Oxide (BeO), thickness range can be 0.25, 0.38, 0.50mm, 0.635mm, 0.76mm, 1.0mm, (default thickness). Thicker thickness such as 1.2mm, 1.6mm or 2.0mm can be customized too.

● Conductor layer materail: Silver-palladium, Gold-palladium, or Mo/Mu+Ni (for Ozone).

● Thickness of conductor: 12um+/-5um normally, and Max can be 20um (0.02mm).

● Min trace width and space: can be 0.30mm/0.30mm for volume production , and 0.20mm/0.20mm is also okay, but cost will be higher, 0.15mm/0.20mm only available for prototype.

● Tolerance for final trace layout: to be +/-10% normally, Resistor value +/-1.0 ohm (or +/-1.0%) with laser trimming.

● Both gold and silver palladium is workable for gold-wire bonding, but customer need to mention that so that we will use special silver palladium which is suitable for that artwork.

● Gold palladium is much more expensive than silver palladium, about 5~10 times higher.

● More different resistors designed on the same board, more expensive the board will be.

● Normally, ceramic PCB layer can be 1-Layer and 2-Layers (with plated through hole (PTH), and plated material is the same like the one used for conductor).

● Soldermask (overglazes or called glass glaze) is also available upon request, working temperature >500 C, and color can be green, blue, black, and semi-transparent.

For more information, Please refer to Thick Film Ceramic PCB.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB