Thick Film Capacitive Sensors

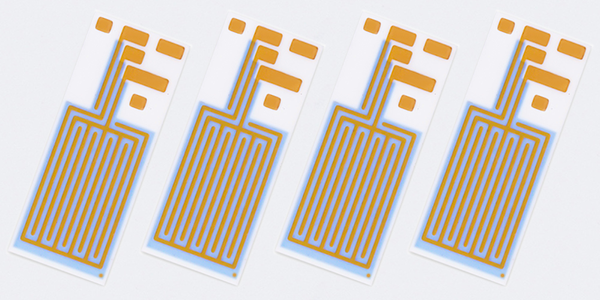

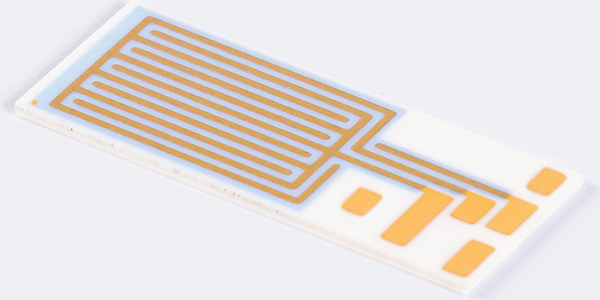

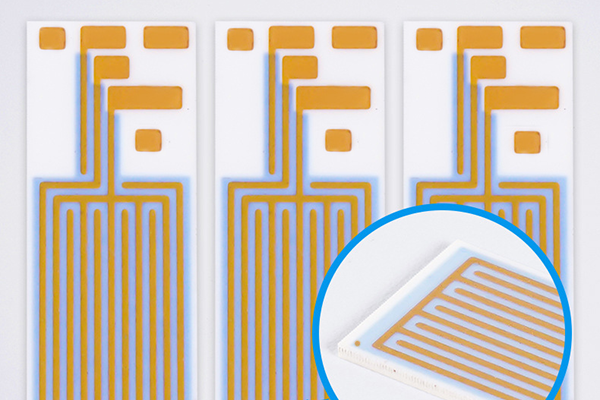

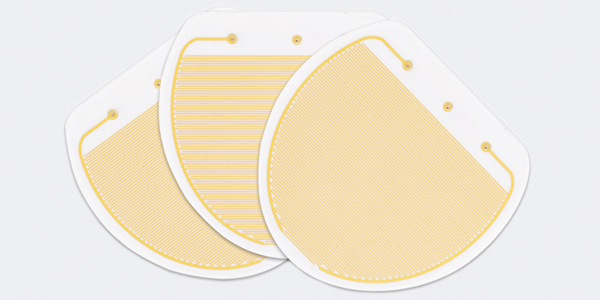

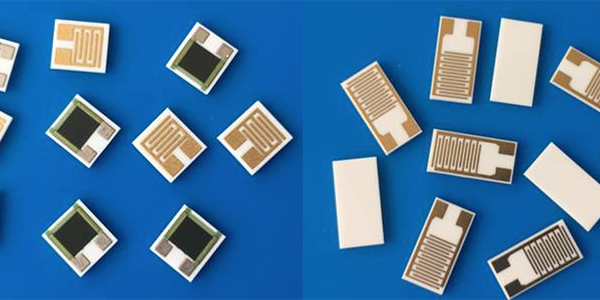

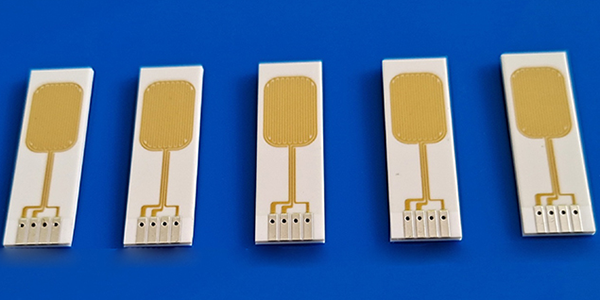

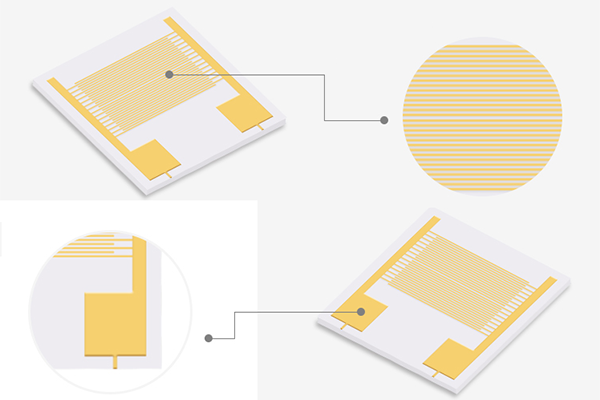

Thick Film Capacitive Sensors, also called Printed Capacitive Sensors are produced using advanced thick film technology, which involves applying electrode, conductive, and insulating materials onto a ceramic substrate through a printing process to create a sensor structure with specific shapes and functions, where the electrode design often features interdigitated patterns to increase the sensing area and enhance sensitivity, while the ceramic substrate, known for its excellent high-temperature resistance and insulation properties, ensures stability for reliable sensor performance in harsh environments.

Thick Film Capacitive Sensors operate based on the detection of changes in capacitance. When external objects or environmental conditions, such as humidity, oil quality, or temperature, change, the electric field around the sensor is altered, leading to a change in capacitance. The interdigitated electrode structure creates a sensing field, and when an object approaches or touches the sensor, it modifies the field distribution, causing a variation in capacitance. The sensor’s circuitry detects these minor capacitance changes and converts the signals, producing measurement data that reflects the changes in the monitored object or environment.

Printed Capacitive Sensors have a wide range of applications. For instance, oil quality sensors are used to monitor the quality and composition of edible oils, detecting changes in oil properties through capacitance variations. Meteorological rain sensors measure precipitation by detecting capacitance changes caused by raindrops. Flat capacitive sensors are commonly used in touchscreens and touchpads, where they sense touch inputs through capacitance changes. Humidity sensors detect environmental moisture variations, often used in environmental monitoring and smart home devices. With their high sensitivity, stability, and broad application range, Printed Thick Film Capacitive Sensors are essential components in modern smart products and environmental monitoring systems.

Characteristics of Thick Film Capacitive Sensors :

● High Sensitivity: Capacitive sensors can accurately detect even the slightest changes in the electric field, making them highly sensitive to external objects or environmental changes. They are especially effective in touch sensing and environmental monitoring, where they can detect subtle variations.

● Strong Stability: The ceramic substrates used in printed thick-film capacitive sensors have excellent high-temperature resistance and good insulation properties, ensuring stable performance in harsh environments, unaffected by temperature fluctuations or humidity.

● Low Power Consumption: Thick Film Capacitive Sensors typically operate with low power, making them ideal for low-power devices, such as smart home products, wearable devices, and more.

● Contactless Operation: Thick Film Capacitive Sensors can detect changes by sensing the proximity or touch of objects, offering a highly effective contactless operation. This is particularly important in applications like touchscreens and other sensor-based devices.

● High Integration: The use of printing technology allows for high integration in the manufacturing process, improving production efficiency and reducing costs. Additionally, this technology allows sensors to be lighter, thinner, and flexible, making them adaptable to different application scenarios.

● Wide Range of Applications: Capacitive sensors are widely used across various fields, including touchscreens, humidity sensing, oil quality detection, meteorological monitoring, and more. They meet the needs of a diverse range of industries such as consumer electronics, environmental monitoring, and industrial applications.

● Durability: The design and materials of printed thick-film capacitive sensors provide high durability, making them resistant to wear and ensuring that they maintain stable performance and accuracy over extended use.

These characteristics make Thick Film Capacitive Sensors an essential component in modern smart devices, environmental monitoring systems, and other high-performance applications.

Thick Film Capacitive Sensors in Edible Oil Monitoring :

Thick Film Capacitive Sensors are increasingly used in the food industry, particularly for monitoring the quality and condition of edible oils. These sensors are incorporated into food quality control systems, and their key applications include:

● Oil Quality Monitoring: Thick Film Capacitive Sensors can detect changes in the dielectric properties of edible oils. The dielectric constant of oil changes based on factors like temperature, moisture, and contamination. The printed thick-film capacitive sensors are designed to sense these changes, providing real-time data on oil quality. This is especially useful in cooking oil monitoring where the oil's degradation level can be tracked, helping to maintain quality and safety.

● Moisture Content Detection: In the context of edible oils, moisture content plays a significant role in their quality. Capacitive sensors can detect the presence of water or other contaminants in the oil. As moisture affects the dielectric constant, the sensor can signal when the oil has absorbed excess moisture, indicating reduced quality or potential spoilage.

● Oil Reusability Detection: Capacitive sensors help determine whether cooking oil has been used beyond its optimal limit. Since oil quality degrades with repeated use, the sensor can monitor the change in dielectric properties to assess the oil's condition. This allows users to determine when to replace the oil to ensure safe cooking.

Printed Capacitive Sensors in Rainfall Monitoring :

In meteorology, Printed Capacitive Sensors are utilized in rainfall monitoring for their precision and reliability. These sensors are employed in weather stations and environmental monitoring systems to measure rainfall and humidity. Specific applications include:

● Rainfall Detection: Printed Capacitive Sensors can be used in rain gauges to detect the presence and intensity of rainfall. The sensor is often designed to monitor the dielectric changes caused by the accumulation of water. As water accumulates on the sensor surface, the change in the capacitive value is used to estimate the amount of rainfall. These sensors are lightweight, durable, and can provide accurate data even in harsh weather conditions.

● Humidity Sensing: Printed Capacitive Sensors can also detect humidity levels in the air. Changes in humidity affect the dielectric properties of the environment, and by monitoring these changes, capacitive sensors can provide insights into local atmospheric conditions. This is useful for weather forecasting and determining the likelihood of precipitation.

● Integration with Weather Stations: Thick Film Capacitive Sensors are easily integrated into automated meteorological systems for continuous monitoring of rainfall and humidity. Their compact size and low power consumption make them ideal for integration into remote or outdoor monitoring devices, where reliable, long-term operation is needed.

Applications of Thick Film Capacitive Sensors :

Thick Film Capacitive Sensors also find important applications in industries like food (oil) monitoring, weather monitoring, and blood testing due to their ability to detect small changes in physical properties and their high sensitivity.

1. Food (Oil) Monitoring

● Oil Quality Monitoring: In the food industry, especially in deep frying or oil-based cooking processes, thick film capacitive sensors are used to monitor the quality of oils. These sensors can detect changes in oil composition, such as degradation or contamination, by measuring properties like dielectric constant and capacitance. When oil undergoes chemical changes due to heating or use, the sensor can detect these changes and alert operators to filter or replace the oil, ensuring food quality and safety.

● Moisture Content Detection: In addition to oil quality, capacitive sensors can also be used to monitor moisture content in food products. For example, sensors can detect the moisture levels in food during processing, packaging, and storage, ensuring consistency and quality. This is particularly useful in baking, snack production, or packaging to preserve freshness.

2. Weather Monitoring

● Humidity and Moisture Measurement: Thick film capacitive sensors are used in weather monitoring systems to measure humidity levels. Capacitive humidity sensors work by measuring the change in capacitance as moisture in the air affects the dielectric properties of the sensor's material. This allows for accurate monitoring of atmospheric humidity, which is vital in weather forecasting, climate studies, and environmental monitoring.

● Rainfall and Soil Moisture Sensing: These sensors can also be applied in environmental monitoring for detecting rainfall or soil moisture levels. By detecting changes in capacitance as the moisture content in the soil increases or decreases, capacitive sensors provide valuable data for agricultural and meteorological studies.

● Temperature Monitoring: Some advanced capacitive sensors are designed to monitor temperature as well, often in combination with humidity sensors. These devices help weather stations monitor changes in temperature and humidity, which are critical data points for accurate weather predictions.

3. Blood Testing and Medical Applications

● Blood Glucose Monitoring: In medical diagnostics, thick film capacitive sensors are used in portable blood glucose meters for diabetes management. These sensors can detect the dielectric properties of blood, which change as glucose levels fluctuate. Capacitive sensors provide a non-invasive and quick method to monitor glucose levels by analyzing the interaction of glucose with the sensor's surface.

● Point-of-Care Diagnostics: Capacitive sensors are increasingly used in point-of-care medical devices for rapid diagnostics. For example, they are used in biosensors to detect the presence of specific biomolecules or pathogens in blood samples. By measuring changes in capacitance, these sensors can help identify conditions such as infections or other blood-related abnormalities.

● Hemoglobin Measurement: In blood tests, capacitive sensors can also measure the amount of hemoglobin present by detecting changes in the blood's dielectric properties, which are influenced by hemoglobin concentration. This allows for quick and accurate detection of anemia or other blood disorders.

● Biochemical Sensing: Capacitive sensors are used in various biochemical sensing applications to detect the presence of specific ions, proteins, or other molecules in blood or bodily fluids. These sensors work by detecting the changes in capacitance caused by the interaction of these molecules with the sensor's surface, providing valuable diagnostic information.

Thick Film Capacitive Sensors are highly sensitive and can detect minute changes in dielectric properties, making them ideal for monitoring processes where small variations matter, such as oil degradation, moisture content, or blood components, these sensors are robust, reliable, and capable of withstanding harsh conditions, which is critical in applications like food processing, weather monitoring, and medical diagnostics. These applications highlight the versatility and precision of thick film capacitive sensors in diverse sectors, making them indispensable tools for improving quality, safety, and efficiency in various industries.

For more information, Please refer to Thick Film Sensors.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

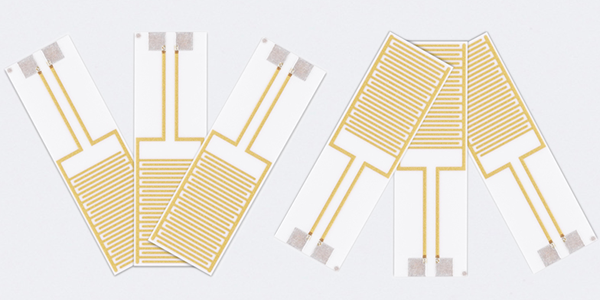

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB