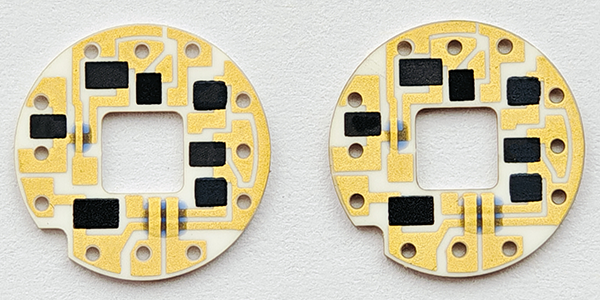

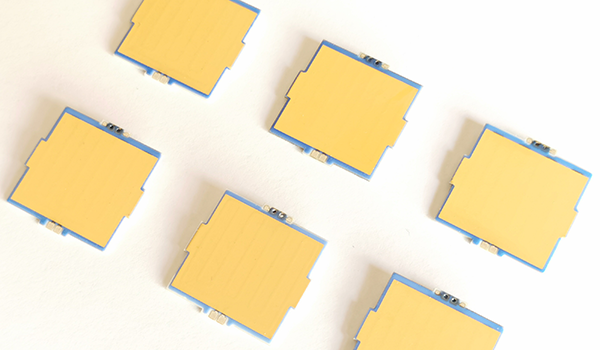

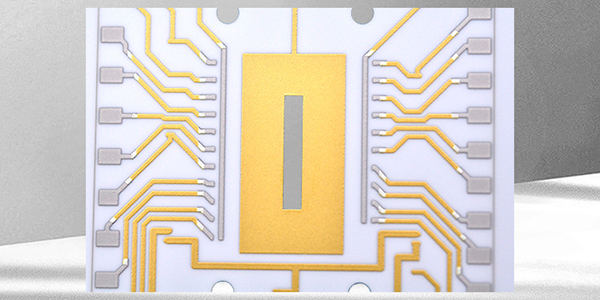

Gold Coated Ceramic Substrates

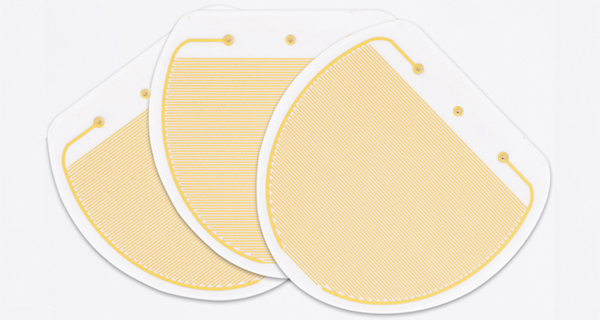

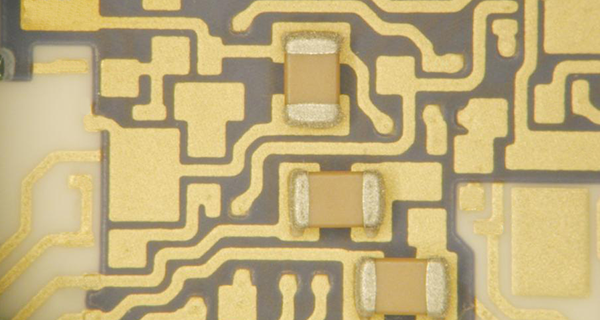

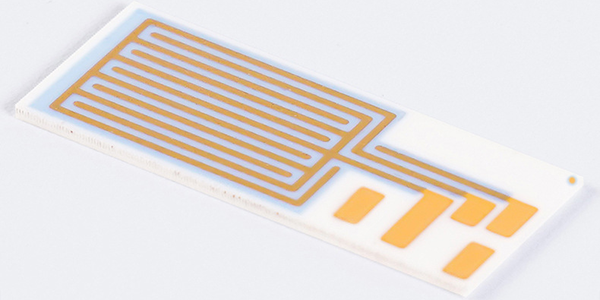

Gold Coated Ceramic Substrates, also called Gold Coated Substrates, are high-performance materials created by applying a thick layer of gold onto ceramic substrates such as aluminum oxide, aluminum nitride, and beryllium oxide through a screen printing process using gold paste, followed by firing and laser trimming to achieve the desired thickness and uniformity, which enhances the material's overall performance for specialized applications and offers a robust solution for high-tech industries.

Gold Coated Ceramic Substrates provide several key benefits, including superior electrical conductivity, corrosion resistance, and biocompatibility. These features make them highly reliable in environments requiring both performance and durability. The adhesion and interfacial properties of the gold coating are essential for ensuring the material's functionality. Furthermore, the gold layer enhances heat resistance and reduces wear, making these substrates ideal for high-temperature and harsh environments.

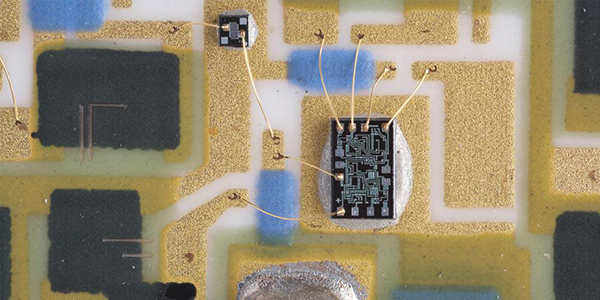

Gold Coated Substrates are widely used in the electronics industry, particularly in applications where high conductivity and durability are essential. They are commonly found in semiconductor devices, high-frequency circuits, and optoelectronics. Additionally, due to their biocompatibility, they are employed in medical devices, while their resilience under extreme conditions makes them suitable for aerospace and automotive sectors. This unique combination of gold and ceramic offers versatility for a range of advanced applications.

Features of Gold Coated Ceramic Substrates :

● High Thermal and Chemical Stability: Gold Coated Ceramic Substrates exhibit excellent resistance to thermal and chemical degradation, ensuring reliability in harsh environments.

● Electrical Conductivity: Gold layer provides excellent electrical conductivity, making these substrates suitable for high-frequency applications.

● Optical Properties: They reflect a broad spectrum of light, with the capability to reflect UV to VIS wavelengths similarly to a gold mirror, which is vital for optical applications.

● Adherence Mechanism: Adherence of the gold layer to the ceramic substrate is facilitated by the formation of an interfacial layer, such as a solid solution of Au-ZrSiO4, and diffusion processes that occur during high-temperature treatments.

● Morphology: The gold films have a granular morphology with grain sizes varying as a function of the film composition, contributing to the film's reflective properties and adherence.

Applications of Gold Coated Substrates :

Gold Coated Substrates have a wide range of potential applications in the electronics industry due to their unique combination of properties. Here are some of the key applications:

● Military and Aerospace: Used in electronic systems due to their stability and performance under extreme conditions.

● Industrial Applications: Suitable for high-temperature and high-reliability applications in various industries.

● Automotive: Employed in sensors and electronic control units that require stable performance.

● Chemical Industry: Used in chemical sensors and other components that need to resist chemical corrosion.

● Biochemical Sensors: Their properties make them ideal for use in sensors that require high sensitivity and stability.

● High-Frequency Applications: Excellent electrical conductivity and thermal stability of gold-coated ceramic substrates make them suitable for high-frequency devices and circuits.

● Microwave Communications: Gold Coated Substrates are used in microwave communication systems due to their good electrical properties, which meet the requirements for high reliability and stability.

● Catalytic Applications: Gold nanoparticles, which can be deposited on ceramic substrates, have exceptional reactivity and broad applicability in catalysis. They are used in various research fields, including energy conversion and medicine.

● Optics and Sensors: Optical properties of gold coatings, such as their ability to reflect a broad spectrum of light, make these substrates useful in optical applications and sensors.

● Magnetic Materials: Gold Coated Substrates can be employed in the development of magnetic materials, which have applications in various electronic devices.

● Electronics Packaging: Due to their excellent thermal conductivity and dimensional stability, these Gold Coated Substrates are used in the packaging of electronic components, including power electronics and multi-chip modules.

● Hybrid Microelectronics: Gold Coated Substrates are utilized in hybrid microelectronics for their ability to provide stable and reliable performance in harsh environments.

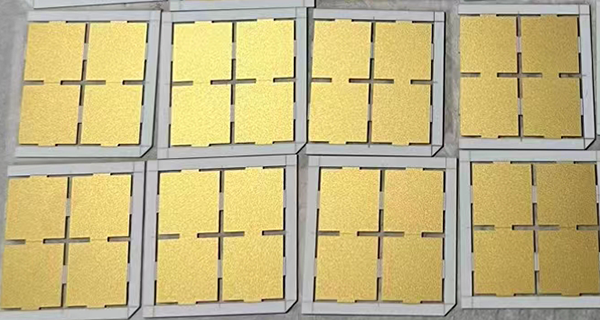

Gold Coated Substrates are designed and manufactured for both low and high volume production, offering a cost-effective solution for a wide range of technical applications where the combination of ceramic and gold properties is beneficial.

Manufacturing Challenges of Gold Coated Ceramic Substrates :

● Adhesion of Conductive Layer: Adhesion strength between the gold film and the Gold Coated Ceramic Substrate is one of the key technical issues. To improve adhesion, techniques like Active Metal Brazing can be employed, which involves adding active elements to the brazing alloy to lower the bonding temperature between the metal and ceramic, thereby enhancing the bonding strength.

● Thermal Expansion Coefficient Matching: Mismatch in the thermal expansion coefficients of the gold film and the ceramic substrate can lead to thermal stress and delamination. Solutions include selecting appropriate ceramic materials such as aluminum oxide (Al2O3), aluminum nitride (AlN), or silicon nitride (Si3N4), which have different thermal expansion coefficients and can better match the gold film.

● Thermal Management: Ceramic substrates need to have good thermal management capabilities for high-power applications. Using materials with high thermal conductivity, such as aluminum nitride ceramic substrates with a thermal conductivity of up to 170 W/m K, can help.

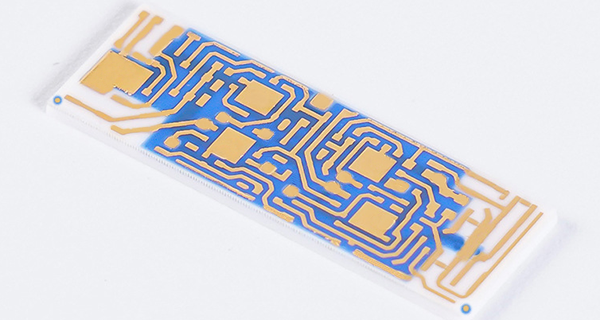

● Precision of Circuit Patterns: Achieving high-precision circuit patterns on ceramic substrates is challenging. Thin-film technology or Direct Plating Copper (DPC) techniques can be used to create fine circuit patterns, where DPC technology uses electrochemical processing to deposit conductive copper and functional film layers, achieving high-precision graphic circuits.

● Manufacturing Cost: The manufacturing cost of Gold Coated Ceramic Substrates is typically high. Thick-Film metallization technology can reduce costs; this technique uses screen printing to apply conductive paste onto the ceramic substrate, followed by high-temperature sintering to bond the metal layer to the ceramic substrate.

● Environmental Protection and Sustainability: With increasing environmental awareness, there is a need to develop more environmentally friendly manufacturing processes. This may include improving electroplating processes, reducing the use of harmful chemicals, and developing recyclable or biodegradable materials.

● Signal Integrity in High-Frequency Applications: Maintaining signal integrity in high-frequency applications is a challenge. Using ceramics with a low dielectric constant and low loss, such as Low Temperature Co-fired Ceramic, can optimize signal transmission and reduce signal delay.

Gold Plated VS Gold Coated Ceramic Substrates :

The terms "Gold-Plated Ceramic Substrates " and "Gold-Coated Ceramic Substrates" refer to different methods of applying gold to a substrate, and there are important differences between these methods, especially in the context of ceramic substrates.

1, Gold Plated Ceramic Substrates :

● Plating Process: Gold plated involves depositing a thin layer of gold onto the substrate using an electrochemical process. This is typically done by immersing the ceramic substrate in a solution containing gold salts and applying an electric current, which causes gold ions to deposit onto the substrate.

● Thickness: Gold plated generally results in a thin layer of gold, often in the range of a few micrometers (µm) or less. The thickness can be controlled to suit specific applications and performance requirements.

● Applications: Gold plating is commonly used in electronic components to provide excellent electrical conductivity, reduce signal loss, and protect against corrosion. It is particularly useful where fine details and precision are required.

● Gold Plating: Generally involves a thin, controlled layer of gold deposited electrochemically. It is used for its precise, thin, and conductive properties in electronics and other high-tech applications.

2, Gold Coated Ceramic Substrates :

● Coating Process: Gold coating can refer to various methods of applying a gold layer to a substrate, not necessarily involving an electrochemical process. This could include techniques like thick film printing circuit (TFPC), physical vapor deposition (PVD), chemical vapor deposition (CVD), or sputtering.

● Thickness: Thickness of gold coating can vary widely depending on the method used and the intended application. Gold coatings can be much thicker than gold plating, potentially in the range of tens to hundreds of micrometers, depending on the needs of the application.

● Applications: Gold coating might be used in applications requiring a more substantial gold layer for enhanced protection or durability. It is used in various industries, including electronics, optics, and decorative applications, where a thicker gold layer might be beneficial.

● Gold Coating: Refers to various methods of applying a gold layer that can be thicker and applied using different techniques. It may be used for more substantial protection or specific functional requirements in different applications.

Both methods aim to enhance the properties of ceramic substrates, but the choice between them depends on the specific requirements of the application, including thickness, durability, and performance needs.

For more information, Please refer to Thick Film Substrates.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

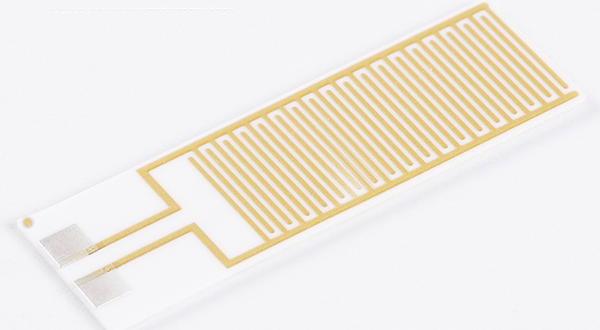

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB