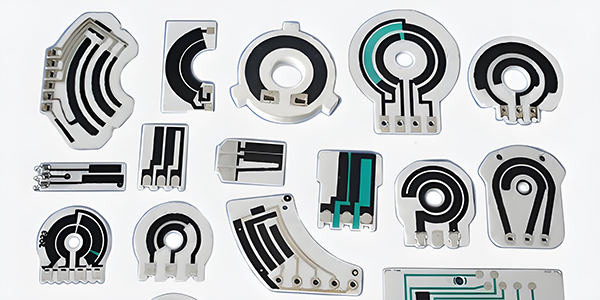

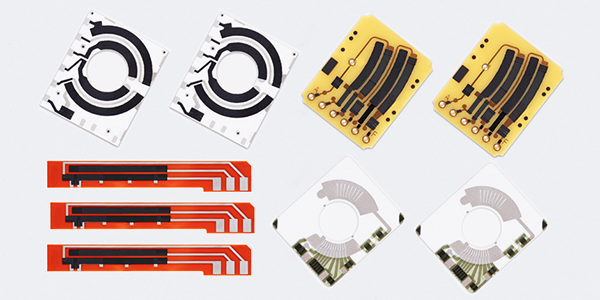

Variable Resistor Carbon PCB

Variable Resistor Carbon PCBs, also called Variable Resistor PCBs, are electronic components designed using thick film resistor technology, incorporating resistive elements that respond to external environmental factors such as temperature, humidity, pressure, or light, and are constructed using screen printing technology that applies conductive, resistive, and insulating pastes onto substrates like FR4, flexible PI, or ceramics, with the resulting resistive elements exhibiting linear resistance variation, enabling the circuit board to function as both a resistor and a sensor for precise environmental measurements.

Variable Resistor Carbon PCBs are manufactured using high-precision Thick Film Resistor Technology. The process involves applying specialized pastes onto selected substrates, followed by curing at high temperatures to form resistive elements. These resistors can be fine-tuned in terms of length, width, and material properties, ensuring high precision and stability in resistance variation. This results in a circuit board capable of delivering precise measurements by altering resistance in response to environmental stimuli, making it crucial for sensor-based applications.

Variable Resistor PCBs play an integral role in various sensor applications across industries that require accurate environmental detection. Commonly used in devices such as temperature sensors, humidity sensors, pressure sensors, and light sensors, these PCBs are applied in smart home systems, automotive electronics, medical devices, industrial automation, and environmental monitoring. By responding to changing environmental conditions, these PCBs provide real-time monitoring, alerting, and fault diagnosis, making them essential in systems that rely on precise feedback and quick responses to external changes.

Advantages of Variable Resistor PCB :

Variable Resistor PCBs are components that allow the adjustment of resistance through variable resistors installed on the circuit boards. This design offers many advantages in electronic products, including:

● Precise Adjustment:

Variable Resistor PCBs allow users to precisely adjust the resistance value to meet different circuit needs. This is particularly important for devices that require flexible adjustment of voltage, current, or signal strength, such as audio systems, temperature control devices, and sensor circuits.

● Space Saving:

By integrating the variable resistor into the PCB design, the need for external adjustment devices is reduced, saving design space. This is especially valuable in small or compact devices where space is limited.

● Simplified Manufacturing Process:

Variable Resistor PCBs can be directly integrated with other components on the circuit board, simplifying the production process and reducing the complexity of assembly and soldering. This reduces the need for additional external components, lowering production costs.

● Stability and Reliability:

Variable resistors on PCBs offer better mechanical stability because they are securely fixed to the circuit board and are less susceptible to external vibrations or interference. Compared to traditional mechanical adjustable resistors, they offer higher reliability over long-term use.

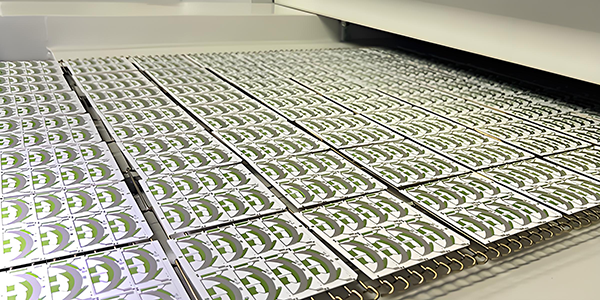

● Automation in Production:

Variable Resistor PCBs support automated assembly and production processes, enabling large-scale production while ensuring consistency and high quality. This is a significant advantage for products that require mass production.

● Cost-Effectiveness:

Using variable resistor PCBs can reduce the number of parts used, lowering the overall cost. Additionally, the integrated design reduces assembly time and labor costs, further improving the product's cost-effectiveness.

● Wide Range of Applications:

Variable Resistor PCBs are widely used in audio adjustment, power management, sensor calibration, display brightness adjustment, and various other electronic devices. They offer good adaptability and multifunctionality.

Variable Resistor PCBs, with their advantages of precise adjustment, space-saving, simplified production, increased reliability, and cost-effectiveness, have become essential components in modern electronic devices, with applications across various fields.

Applications of Variable Resistor Carbon PCB :

Variable Resistor Carbon PCBs have wide applications in many fields, thanks to its ability to precisely sense environmental changes and convert them into electrical signals. Below are some specific application areas:

● Temperature Sensors:

Variable Resistor Carbon PCBs are commonly used in temperature detection devices. When the temperature changes, the resistance value on the PCB changes, which in turn affects the current and voltage signals. By measuring these changes, the temperature can be accurately monitored and controlled, commonly used in air conditioning, household appliances, industrial equipment, and automotive systems.

● Humidity Sensors:

Variable Resistor Carbon PCBs can also be used in humidity sensors. Changes in humidity cause variations in resistance, which affect the circuit output. Humidity sensors are widely used in climate control systems, agricultural environmental monitoring, smart homes, and more.

● Pressure Sensors:

In industrial automation and medical devices, variable resistor carbon PCBs can be used for pressure detection. As pressure changes, the resistance in the PCB also changes, providing accurate pressure data, suitable for gas and liquid pressure measurement as well as liquid level monitoring.

● Light Sensors:

Variable Resistor Carbon PCBs can detect changes in ambient light intensity. For example, when light intensity changes, the resistance will vary, which is suitable for automatically adjusting lighting systems, outdoor environmental monitoring, and light detection in solar panels.

● Automotive Electronics:

Variable Resistor Carbon PCBs are widely used in various electronic systems in vehicles, such as temperature control systems, seat position adjustments, air conditioning systems, and speed control. These sensors provide accurate real-time data to ensure the efficient operation of the systems.

● Medical Equipment:

In the medical field, variable resistor carbon PCBs are used in devices such as heart rate monitors, blood pressure meters, and body temperature monitors. They can accurately detect physiological signals from the human body and convert them into electrical signals for real-time analysis, assisting doctors in making judgments.

● Smart Home Systems:

In smart home devices, variable resistor carbon PCBs are commonly used to detect environmental changes, such as indoor temperature and humidity monitoring, air quality detection, and automatic control of curtains or lights. These sensors provide data to support intelligent device control.

● Environmental Monitoring:

Variable Resistor Carbon PCBs are also widely used in environmental monitoring fields to detect parameters such as air quality, temperature, humidity, and pressure. This data can be used in environmental protection, disaster warning systems, and other applications to enable timely responses.

● Industrial Automation:

In industrial production, variable resistor carbon PCBs can be used for equipment status monitoring, such as vibration sensing, flow sensing, and temperature monitoring. These sensors enhance the precision and efficiency of production processes and enable fault diagnosis and early warnings.

● Consumer Electronics:

In many consumer electronic products, such as smartwatches, health monitoring devices, and smart temperature control devices, variable resistor carbon PCBs are used to detect parameters like temperature, humidity, and pressure, providing users with convenient operation and data feedback.

Through these applications, Variable Resistor Carbon PCBs can provide accurate environmental sensing for various devices, meeting the needs of intelligence, automation, and precise monitoring.

Variable Resistor Carbon PCB For LP Gas Tank Gauges :

Variable Resistor Carbon PCBs are widely used in LP (Liquefied Petroleum) gas tank gauges to measure the remaining gas level. The working principle can be understood through the following steps:

● Float and Resistance Variation:

Inside the LP gas tank, a float (usually a small floating marker) moves up or down with the change in the liquid level of the gas inside the tank. The movement of the float is directly connected to the variable resistor sensor. The core component of this sensor is a variable resistor, and as the float moves, the resistance value changes.

● Relationship Between Resistance Change and Electrical Signal:

When the float rises or falls with the liquid level, the resistance of the resistor changes accordingly. This change is converted into an electrical signal, usually in the form of voltage or current. By monitoring these changes, the liquid level of the gas inside the tank can be determined.

● Sensor Output and Display Connection:

This electrical signal is connected to a display device (such as a digital screen, analog pointer gauge, or other monitoring devices). The display shows the remaining gas level in real-time, helping users monitor gas usage and avoid running out of gas.

● Calibration and Accuracy:

The variable resistor sensor usually needs to be calibrated during installation to ensure that it accurately reflects changes in the liquid level. By precisely adjusting the resistor range, the readings displayed can be made accurate for different gas levels.

Variable Resistor Carbon PCBs in an LP gas tank gauge works by the float's movement, which drives changes in the resistance, converting these changes into electrical signals to be displayed, thus helping users monitor the remaining gas level. This technology is reliable, cost-effective, and easy to maintain, making it widely used in household, industrial, and automotive gas monitoring applications.

Variable Resistor PCB For Automotive Sensors :

Variable Resistor PCBs are increasingly used in automotive sensors due to their ability to provide precise signal adjustment and sensing functions. They are applied in various automotive systems. Below are some common automotive sensor applications:

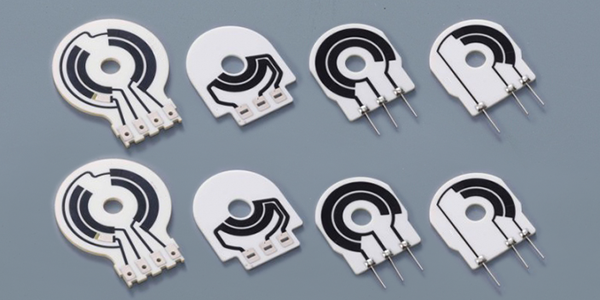

● Throttle Position Sensor (TPS):

Throttle position sensor is used to detect the throttle's opening degree and transmit data to the vehicle's Engine Control Unit (ECU). It uses the variable resistor principle to sense the changes in throttle position, helping the engine control system optimize fuel injection and air intake, ensuring efficient engine operation.

● Accelerator Pedal Position Sensor:

Accelerator pedal position sensor detects the driver's pedal pressure and converts this signal into an electrical signal sent to the ECU. The variable resistor PCB accurately reflects even slight changes in pedal position, enabling the engine control system to adjust the throttle response promptly, enhancing acceleration performance and driving experience.

● Fuel Tank Level Sensor:

Fuel tank level sensor measures the fuel level in the tank and sends the data back to the vehicle's control system. Sensors using the variable resistor principle can precisely detect the liquid level changes, ensuring the fuel measurement system accurately displays fuel levels, helping the driver monitor the remaining fuel and avoid running out.

● Temperature Sensors:

Temperature sensors in vehicles, such as engine temperature sensors and cabin temperature sensors, often use variable resistor PCBs. By measuring temperature changes, the sensor adjusts its resistance value, transmitting the temperature data to the vehicle control system, ensuring both engine performance and interior comfort and safety.

● Pressure Sensors:

The use of variable resistor PCBs in pressure sensors is also common, especially for measuring the pressure in automotive components like tires, fuel systems, and air compression systems. By changing the resistance, pressure sensors can precisely reflect pressure data and transmit it to the vehicle's electronic systems in real time.

By using Variable Resistor PCB Technology, automotive sensors can achieve higher performance, precision, and reliability, improving the intelligence and stability of the entire vehicle's electronic system. This technology is an indispensable part of modern automotive design.

For more information, Please refer to Thick Film Sensors.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB