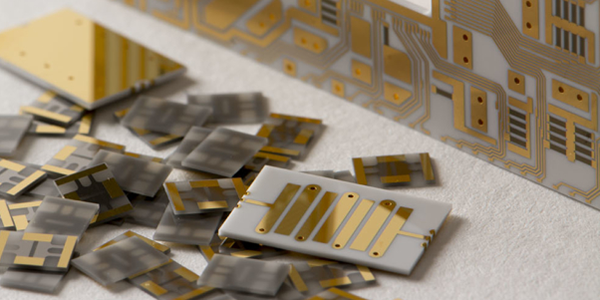

HTCC / LTCC Metallization Technologies

HTCC (High-Temperature Co-fired Ceramic) and LTCC (Low-Temperature Co-fired Ceramic) are ceramic metallization technologies, differentiated by sintering temperatures and applications. HTCC, sintered at 1400°C–1600°C, is suited for high-power, high-temperature applications with fewer layers (3-5), offering better temperature stability. LTCC, sintered at 850°C–900°C, is ideal for high-frequency, high-density circuits, supporting more layers (6-20+ layers) and fine interconnections, commonly used in RF and sensor applications.

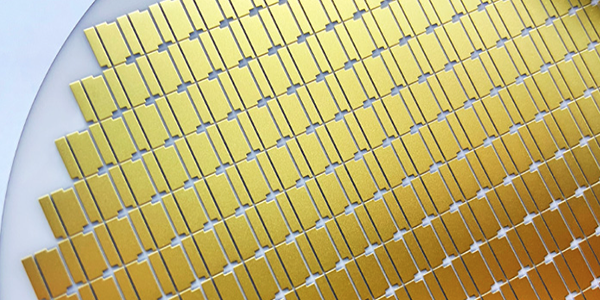

HTCC (High-Temperature Co-fired Ceramic) is a manufacturing process that utilizes high-temperature sintering technology to co-sinter ceramic substrates and metal materials together. In the HTCC process, ceramic substrates and metal circuits are typically sintered at temperatures ranging from 1400°C to 1600°C. The main feature of this process is that the ceramic substrate and metal circuit are tightly bonded through co-sintering, resulting in strong mechanical strength and thermal stability. HTCC is widely used in high-power, high-frequency electronic components, such as RF modules and power amplifiers, which require high performance.

LTCC (Low-Temperature Co-fired Ceramic) is a manufacturing process that differs from HTCC by using a lower sintering temperature, typically ranging from 850°C to 1000°C, to co-sinter metals and ceramics. The ceramic substrates used in LTCC are typically made from low-temperature co-fired ceramic materials (such as glass ceramics), which allows for compatibility with a wider range of metal materials. Due to the lower sintering temperature, the LTCC process can achieve more detailed circuit designs and higher integration levels. It is particularly suitable for applications requiring complex multilayer structures and precise circuits, and is widely used in fields such as communications, medical devices, and automotive electronics.

HTCC and LTCC differ in several key product characteristics. HTCC-processed ceramic substrates typically offer higher thermal conductivity, mechanical strength, and resistance to high temperatures, making them suitable for high-power, high-temperature environments. However, due to the higher sintering temperature, material options are more limited, and the manufacturing process is more complex. In contrast, LTCC, with its lower sintering temperature, provides greater design flexibility, enabling more precise circuit layouts, especially for multilayer structures and high-density packaging. LTCC products generally offer better electrical performance, lower loss, and higher integration and miniaturization, making them ideal for high-frequency, high-speed circuits.

Comparison of HTCC and LTCC :

HTCC (High-Temperature Co-fired Ceramic) and LTCC (Low-Temperature Co-fired Ceramic) are two common co-fired ceramic technologies. They differ significantly in production processes, product applications, advantages, and disadvantages.

1. Manufacturing Process:

HTCC:

● Sintering Temperature: HTCC has a high sintering temperature, typically ranging from 1400°C to 1600°C.

● Material Selection: HTCC commonly uses high-temperature ceramics such as alumina (Al₂O₃) or aluminum nitride (AlN), which offer good high-temperature stability and thermal conductivity.

● Processing Complexity: Due to the high sintering temperature, material selection and processing are more complex. The metal circuits and ceramic substrates must have good thermal expansion matching.

LTCC:

● Sintering Temperature: LTCC has a lower sintering temperature, typically between 850°C and 1000°C.

● Material Selection: LTCC typically uses low-temperature co-fired ceramic materials (such as glass-ceramics or lead titanate ceramics), which can sinter at lower temperatures and are compatible with metal materials.

● Processing Complexity: With a lower sintering temperature, LTCC allows for greater flexibility in manufacturing, enabling finer circuit designs and multi-layer structures.

2. Product Applications:

HTCC:

● High-Power Electronics: HTCC is used for high-power, high-frequency applications, such as RF modules, microwave devices, power amplifiers, lasers, satellite communications, etc.

● High-Temperature Environments: It is suitable for high-temperature environments, especially for applications requiring high thermal conductivity and temperature resistance, such as aerospace and automotive electronics.

LTCC:

● Multi-Layer Integrated Circuits: LTCC is widely used for manufacturing multi-layer circuit boards, particularly in fields like communication, automotive electronics, and medical devices. It is ideal for applications requiring miniaturization, high-density integration, and precise circuit design.

● High-Frequency, High-Speed Circuits: LTCC is also well-suited for high-frequency, high-speed circuits (e.g., 5G base stations and power electronics) that require low loss and good electrical performance.

3. Advantages and Disadvantages Comparison:

Advantages of HTCC:

● Good High-Temperature Performance: HTCC offers excellent high-temperature performance, making it suitable for high-power and high-temperature applications.

● High Mechanical Strength: HTCC materials typically have high mechanical strength and good thermal stability due to the high sintering temperature.

● High Thermal Conductivity: Some HTCC materials, like aluminum nitride, have high thermal conductivity, which aids in heat dissipation.

Disadvantages of HTCC:

● High Sintering Temperature: The high sintering temperature requires special equipment and can be challenging in terms of material selection and process control.

● Lower Design Flexibility: Due to the high sintering temperature, design flexibility may be limited, and circuit structure and dimensions may face constraints.

● Higher Costs: Due to the complexity of the process and the materials, HTCC typically has higher production costs.

Advantages of LTCC:

● Low Sintering Temperature: LTCC's low sintering temperature allows for more material compatibility, and the manufacturing process is more flexible, supporting multi-layer integrated designs.

● Finer Circuit Design: The lower sintering temperature allows for more precise circuit layouts and higher-density integration, which is ideal for complex, multi-layer circuits.

● Higher Integration: LTCC supports high-density packaging and multi-layer circuit designs, making it suitable for modern applications like communications, medical devices, and automotive electronics.

● Lower Cost: Compared to HTCC, LTCC has lower sintering temperatures and process complexity, leading to a more cost-effective production process.

Disadvantages of LTCC:

● Poor High-Temperature Performance: LTCC is not suitable for high-temperature environments, making it less ideal for high-power applications.

● Lower Thermal Conductivity: LTCC typically has lower thermal conductivity than HTCC, which limits its use in high-power devices where heat dissipation is critical.

● Electrical Performance Variability: While LTCC works well for high-frequency applications, its electrical performance may be inferior to HTCC in high-voltage, high-power scenarios.

HTCC is suitable for high-temperature, high-power environments, while LTCC is better for applications requiring high integration, miniaturization, and cost-efficiency. The choice between the two depends on the specific needs of the application.

Multilayer Circuits of HTCC VS LTCC :

HTCC and LTCC technologies have distinct differences in their capabilities for achieving multi-layer circuits, due to their different sintering temperatures, material properties, and process requirements. Here's an overview of their capabilities regarding multi-layer circuit designs.

1. HTCC (High-Temperature Co-fired Ceramics) :

● Number of Layers: HTCC technology is typically used for packaging at higher temperatures, with sintering temperatures ranging from 1400°C to 1600°C. Due to the high sintering temperature, the multi-layer circuit designs are generally simpler, supporting fewer layers. In general, HTCC technology typically supports 3 to 5 layers of circuitry.

● Reasons:

● The high sintering temperature of HTCC limits the number of layers that can be stacked.

● HTCC materials are often harder and more brittle, which makes it difficult to achieve fine interconnects and complex circuit designs, limiting its use in more complex multi-layer circuits.

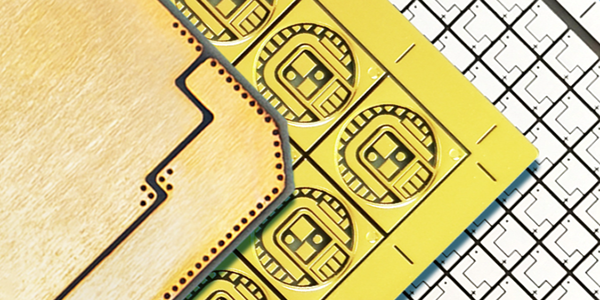

2. LTCC (Low-Temperature Co-fired Ceramics) :

● Number of Layers: LTCC technology can support a greater number of layers, typically allowing for 6 to 20 layers of circuitry. In some high-end applications, it can even achieve 30+ layers. This is especially true for complex microwave circuits and high-frequency applications.

● Reasons:

● LTCC uses materials that sinter at lower temperatures (approximately 850°C to 900°C), which enables the stacking of more layers in a multi-layer circuit.

● LTCC's multi-layer circuits are made possible by connecting different ceramic layers with interconnections, which allows for higher integration and more complex circuit designs.

● LTCC is more compatible with fine interconnects and higher circuit densities, making it suitable for multi-layer designs in high-frequency, microwave, and sensor applications.

HTCC: Typically supports 3 to 5 layers of circuitry, ideal for high-temperature, high-power, and high-frequency applications, with an emphasis on reliability and thermal stability.

LTCC: Can support 6 to 20 layers of circuitry, and in some cases even more, making it suitable for high-density, multi-layer circuits and high-frequency, RF applications, commonly used in microwave and sensor-based designs.

If higher circuit integration and multi-layer designs are needed, LTCC is the better choice, while HTCC is more suitable for circuits that require high-temperature and high-power packaging.

For more information, Please refer to Thick Film Substrates.

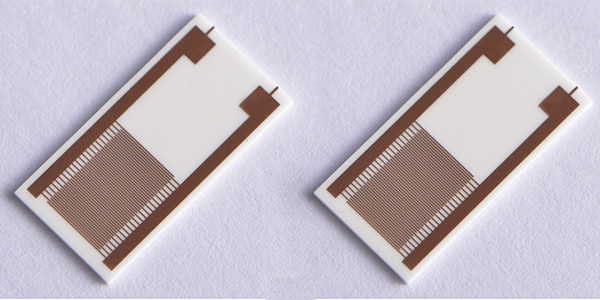

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

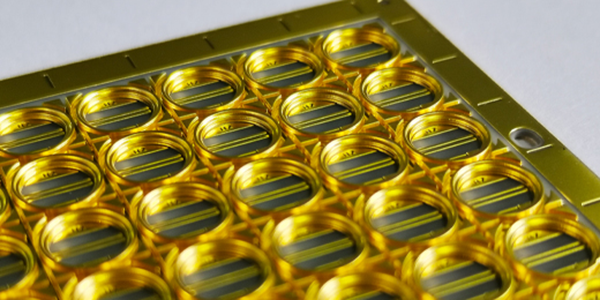

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

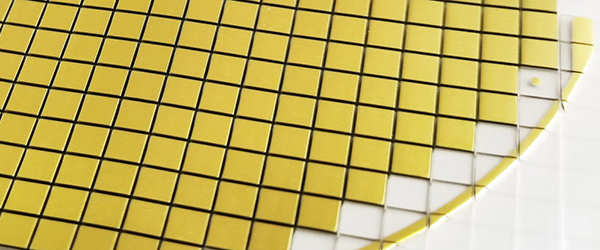

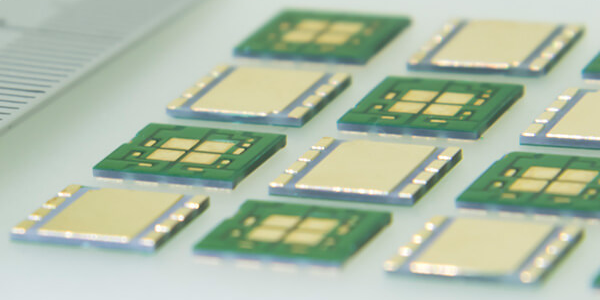

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

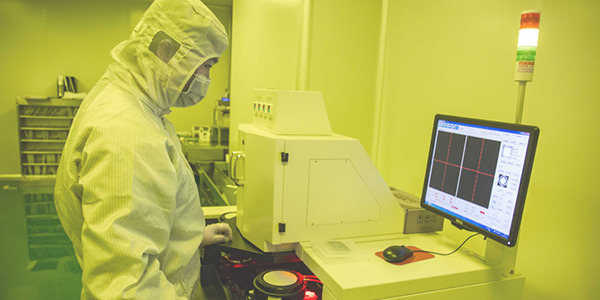

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB