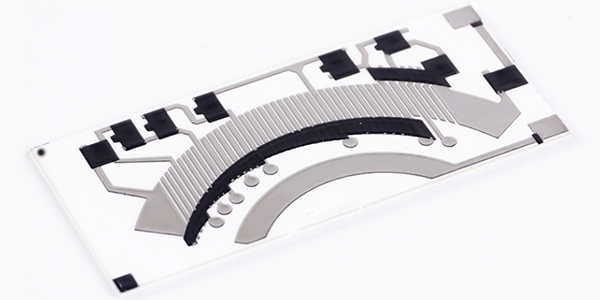

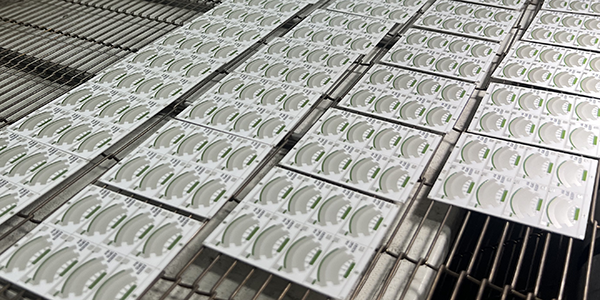

Oil Level Sensor PCB

Oil Level Sensor PCBs, also called Oil Level Sender PCBs, are high-performance circuit boards designed for precise measurement and monitoring of oil levels, utilizing thick-film technology combined with ceramic substrates to detect changes in electrical properties when the substrate comes into contact with oil, providing reliable oil level readings and ensuring that mechanical systems in automotive, industrial, and aerospace applications receive critical oil information, which is essential for maintaining safe operation and extending the lifespan of equipment.

Oil Level Sensor PCBs are produced through a detailed and precise manufacturing process. The first step involves preparing the ceramic substrate to meet the required dimensions and thickness. Next, screen printing technology is employed to apply thick-film conductive pastes onto the substrate, creating the necessary circuit patterns. The printed layers are then subjected to a high-temperature sintering process (typically between 850°C and 1000°C) to ensure strong adhesion to the ceramic substrate. Afterward, various sensing components, such as resistors and capacitors, are integrated into the circuit, followed by the assembly of electronic components. Finally, the sensor undergoes sealing and rigorous testing to ensure its accuracy and reliability in diverse operating conditions.

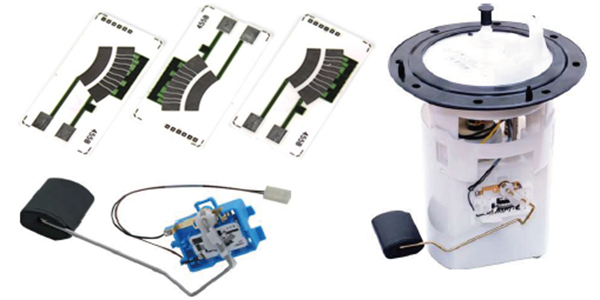

Oil Level Sender PCBs are widely utilized in a range of industries, including automotive, industrial machinery, aerospace, marine, and oil & gas. In the automotive sector, these sensors are used to monitor oil levels in engines and transmissions, contributing to vehicle maintenance and performance. In industrial applications, Oil Level Sensor PCBs are found in compressors, pumps, turbines, and hydraulic systems. For aerospace and marine environments, they provide accurate monitoring of oil levels in high-temperature and high-pressure conditions. Additionally, their durability and corrosion resistance make them ideal for use in the oil and gas industry, where they are employed in monitoring oil levels in drilling equipment and offshore platforms. These sensors offer crucial attributes such as high thermal resistance, electrical insulation, and chemical resistance, ensuring long-term stability and reliable operation in demanding environments.

Advantages of Oil Level Sensor PCB :

● High Precision and Accuracy: Oil Level Sensor PCBs provide accurate oil level measurements by detecting changes in electrical properties when the ceramic substrate interacts with the oil, ensuring precise monitoring of oil levels even in challenging environments.

● Durability and Reliability: The use of ceramic substrates and thick-film technology enhances the durability of these sensors, enabling them to withstand high temperatures, pressure, and harsh chemicals, making them highly reliable for long-term use in demanding conditions.

● Corrosion and Wear Resistance: Oil Level Sensor PCBs are highly resistant to corrosion, ensuring consistent performance even in corrosive environments such as those found in the oil and gas industry, marine applications, and high-moisture areas.

● Compact and Robust Design: These sensors feature a compact design that is ideal for tight spaces, while the robust construction ensures they can handle mechanical stress and vibrations typically encountered in automotive engines, industrial machinery, and aerospace systems.

● Energy Efficiency: Oil Level Sensor PCBs are designed to operate with minimal power consumption, making them energy-efficient and suitable for integration into systems where power usage is a concern.

● Wide Range of Applications: Due to their versatility, Oil Level Sensor PCBs are widely used in various fields, including automotive oil monitoring, industrial hydraulics, aerospace systems, and marine engines, providing a reliable solution for diverse monitoring needs.

● Cost-Effectiveness: The manufacturing process of Oil Level Sensor PCBs is cost-effective, providing an affordable solution for oil level monitoring without compromising on performance, making them an economical choice for large-scale applications.

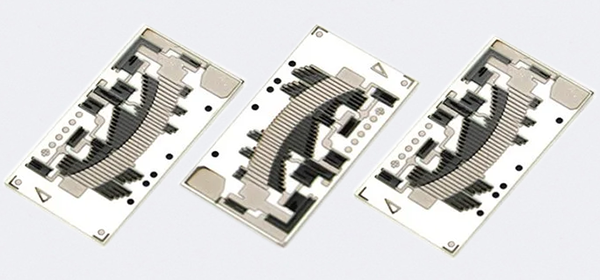

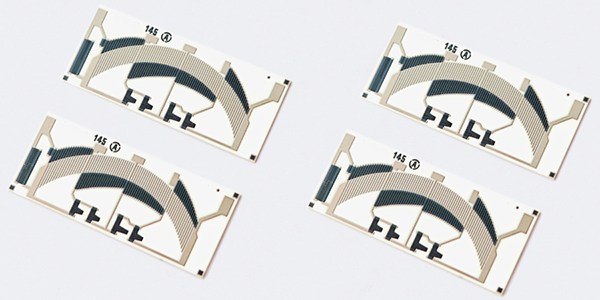

● Customizability: Oil Level Sensor PCBs can be customized to meet specific requirements, such as size, shape, and performance specifications, allowing manufacturers to tailor the sensors to the unique needs of different applications, offering greater flexibility and versatility in product design.

Applications of Oil Level Sensor PCB :

● Automotive Industry: In vehicles, the Oil Level Sensor PCB is crucial for monitoring engine oil levels to prevent engine damage due to insufficient lubrication.

● Industrial Machinery: Machinery in various industries such as manufacturing, mining, and construction rely on the Oil Level Sensor PCB to ensure the proper functioning of hydraulic systems and gearboxes.

● Aerospace: Aircraft and spacecraft utilize these sensors to monitor critical fluid levels for engines and other systems, ensuring safety and reliability during operation.

● Marine Applications: Ships and submarines use Oil Level Sensor PCBs to monitor the levels of various fluids, including engine oil, ensuring the smooth operation of marine engines.

● Power Generation: Power plants use these sensors to monitor the oil levels in turbines and generators, preventing equipment failure and ensuring continuous power supply.

● Medical Equipment: In the medical field, the Oil Level Sensor PCB can be used in devices that require precise fluid management, such as infusion pumps and diagnostic equipment.

Manufacturing Processes of Oil Level Sender PCB :

● Ceramic Substrate Preparation:

The process begins with selecting and preparing a ceramic substrate, which serves as the foundation for the PCB. The ceramic material must meet specific dimensional and thickness requirements to ensure optimal performance. The ceramic is cut, cleaned, and prepped for the next steps.

● Screen Printing of Conductive Layers:

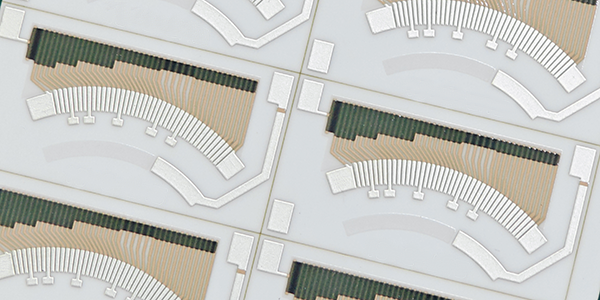

Once the ceramic substrate is ready, a screen printing technique is used to apply thick-film conductive pastes onto the surface of the substrate. These conductive pastes form the electrical pathways or circuits required for the sensor’s functionality. The printing process must be precise to ensure uniformity and accuracy in the layout.

● High-Temperature Sintering:

After the conductive pastes are applied, the substrate undergoes a high-temperature sintering process, typically between 850°C and 1000°C. This process fuses the conductive materials to the ceramic substrate, ensuring strong adhesion and stability. Sintering also enhances the electrical and thermal properties of the sensor.

● Integration of Sensing Elements:

Once the conductive layers are set, various sensing components, such as resistors and capacitors, are integrated into the circuit. These elements are placed with high precision to enable accurate monitoring of oil levels. The integration of these components is a critical step to ensure reliable sensor performance.

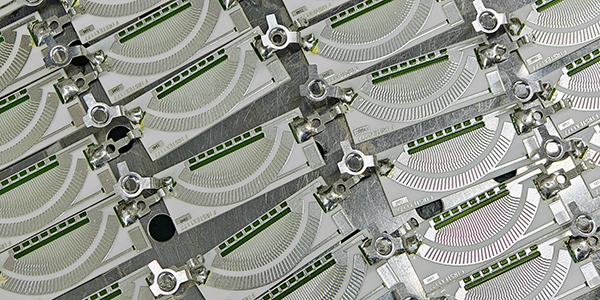

● Assembly of Electronic Components:

Following the integration of sensing elements, electronic components such as connectors, transistors, and resistors are assembled onto the Oil Level Sender PCB. This step requires fine-pitch placement to ensure the components fit within the compact space of the sensor design.

● Encapsulation and Sealing:

To protect the PCB from environmental factors like moisture, dust, and chemicals, the sensor undergoes an encapsulation and sealing process. This step ensures the longevity of the sensor by providing a durable protective layer that prevents damage to the electronic components.

● Testing and Calibration:

Once assembled, the Oil Level Sender PCBs undergo rigorous testing and calibration. This stage ensures that the sensors function accurately and reliably across a range of conditions. Each sensor is tested for performance characteristics such as sensitivity, response time, and electrical resistance. Any sensor that does not meet the required specifications is discarded or reworked.

● Final Inspection and Quality Control:

The final step involves a thorough inspection of the completed Oil Level Sender PCBs. The sensors undergo visual inspections to check for defects in the assembly, as well as more technical assessments to ensure that the sensors meet the standards for functionality, durability, and accuracy. Only those sensors that pass this rigorous quality control process are packaged for shipment.

Design Considerations of Oil Level Sensor PCB :

When designing Oil Level Sensor PCBs, several important factors must be taken into account to ensure the sensors' performance, durability, and accuracy in various applications. Below are the key design considerations:

● Material Selection:

The choice of materials for the PCB, especially the ceramic substrate and thick-film conductive pastes, is critical. The ceramic substrate must be chosen for its thermal stability, electrical insulation, and chemical resistance, ensuring it can withstand the challenging environments in which the sensor will be used. The conductive pastes should provide good adhesion and conductivity, ensuring the sensor's long-term reliability.

● Sensor Sensitivity:

The sensitivity of the sensor must be optimized to accurately detect oil level changes. The design of the conductive circuits and the integration of sensing elements, such as resistors and capacitors, should ensure that even small changes in oil level result in measurable electrical changes, providing precise oil level readings.

● Temperature and Pressure Resistance:

Oil Level Sensor PCBs are often used in environments with extreme temperature and pressure fluctuations. The design must ensure that the materials and components used can withstand high temperatures (ranging from 850°C to 1000°C during sintering) and pressure variations, particularly in automotive, aerospace, and industrial applications.

● Corrosion and Chemical Resistance:

The design must take into account the potential exposure to corrosive substances, such as oil, gas, and other chemicals. The ceramic substrate and the sensor's protective coatings should be resistant to corrosion to maintain the sensor's functionality over time, especially in industries like oil and gas, marine, and industrial machinery.

● Mechanical Stress and Vibration Resistance:

Given that Oil Level Sensor PCBs are often used in engines and machinery subject to vibrations and mechanical stress, the design must ensure that the sensor is robust enough to resist these forces without degrading performance. The design should include features that help mitigate the effects of vibrations, such as reinforcing the PCB structure or choosing materials with inherent durability.

● Compact and Space-Efficient Design:

Oil Level Sensor PCBs are often used in compact spaces, particularly in automotive and aerospace applications. The design must prioritize compactness while maintaining the necessary functionality and robustness. This requires careful planning of the component placement and the use of small, efficient electronic components.

● Energy Efficiency:

The design of Oil Level Sensor PCBs must also consider power consumption. The sensors should be designed to consume minimal energy, making them suitable for integration into systems with low-power requirements. This is particularly important for applications in remote or battery-powered systems.

● Customization for Specific Applications:

Design flexibility is crucial, as Oil Level Sensor PCBs may need to be customized for different applications. Factors such as the size of the sensor, the environmental conditions it will operate in, and the specific oil monitoring requirements should be considered. Customization can involve adjusting the layout, materials, or components to meet the specific needs of the customer.

● Sealing and Encapsulation:

The design must ensure that the PCB is adequately sealed and protected from environmental factors like moisture, dust, and chemicals. This includes considering the type of encapsulation material to be used, which should offer high durability while not interfering with the sensor's functionality.

● Testing and Calibration:

Designers must plan for testing and calibration of the PCB sensor. This involves designing the PCB to be easily testable to ensure accurate readings across different conditions. It also means providing the necessary testing points and connections that facilitate the calibration process.

For more information, Please refer to Thick Film Sensors.

Custom Thick Film Sensors

- Custom Thick Film Sensor Elements

- Fuel Level Sensor PCB

- Fuel Level Sensor Ceramic PCB

- Oil Level Sensor Ceramic PCB

- Motorcycle Fuel Level Sensor PCB

- Throttle Position Sensor PCB

- Throttle Position Sensor FR4 PCB

- Throttle Position Sensor Ceramic PCB

- Throttle Position Sensor Flexible PCB

- Accelerator Pedal Sensor PCB

- Accelerator Pedal Position Sensor PCB

- Pedal Position Sensor Carbon PCB

- Potentiometer PCB

- Linear Potentiometer Carbon Track PCB

- Rotary Potentiometer Carbon Track PCB

- FR4 Potentiometer Carbon PCB

- Ceramic Potentiometer Carbon PCB

- Flexible Potentiometer Carbon PCB

- Logarithmic Taper Potentiometer PCB

- Position Sensor PCB

- FR4 Position Sensor Carbon PCB

- Ceramic Position Sensor Carbon PCB

- Flexible Position Sensor Carbon PCB

- Flexible Sensor PCB

- Printed Flexible Electronic PCB

- Printed Carbon PCB

- Ceramic Pressure Sensors

- Ceramic Thick Film Pressure Sensors

- Engine Oil Pressure Sensor PCB

- Gold Coated Ceramic Substrates

- Gold Coated Thick Film Substrates

- Metallized Ceramic Substrates

- Multilayer Thick Film Substrates

- Thick Film Metallization Technology

- Thin Film Metallization Technology

- Thin Film Ceramic PCB

- Variable Resistor Carbon PCB

- Remote Ready Sender Ceramic PCB

- LP Gas Tank Gauges Ceramic PCB

- Thick Film Capacitive Sensors

- Thick Film Capacitive Pressure Sensors

- Thick Film Edible Oil Quality Sensors

- Thick Film Meteorological Rainfall Sensors

- PI Interdigital Electrodes (Flexible)

- Air Door Actuator PCB

- HVAC Blend Door Actuator PCB